Switching to lightweight materials can cut printing costs significantly. Here’s how:

- Cost Savings: Reducing material weight by 10% can lower manufacturing costs by 4%.

- Shipping Efficiency: Lighter materials reduce shipping costs and import tariffs.

- Production Benefits: Lightweight materials require less raw material, reduce ink usage, and minimize machine jams.

- Durability: Materials like PLA, PETG, and ABS offer high strength without added weight.

- Environmental Perks: Lighter shipments reduce fuel use and carbon emissions.

Quick Comparison: Lightweight vs. Heavy Materials

| Feature | Lightweight Materials | Heavy Materials |

|---|---|---|

| Cost | Lower | Higher |

| Shipping | Cheaper | Expensive |

| Durability | Moderate | High |

| Print Quality | Good but softer ink retention | Sharper and vibrant |

| Environmental Impact | Lower carbon footprint | Higher resource usage |

Lightweight materials are ideal for reducing costs while maintaining quality and sustainability. For tailored solutions, consult experts like Miro Printing & Graphics Inc..

Why Material Weight Affects Printing Costs

Understanding how material weight influences costs is key to making smart decisions about lightweight materials. The weight of your materials impacts everything – from production and shipping to storage and handling. Heavier materials not only cost more upfront but also lead to higher transportation and operational expenses. This makes selecting lighter materials an effective way to manage overall costs.

Production Costs

The weight of the paper you choose directly affects production expenses. Heavier paper requires more raw materials, which increases the base cost. Additionally, heavier paper often needs specific ink profiles. If these aren’t calibrated correctly, you could end up using more ink than necessary, cutting into your profits. On the other hand, lighter paper tends to be less prone to jams and works better for high-volume printing jobs.

For reference, standard bond paper comes in weights like 16, 20, 24, 28, 32, and 36 pounds, while text paper is typically available in 50, 60, 70, 80, and 100-pound options. Each weight has specific handling requirements and can affect the performance of your printing equipment. By optimizing your production processes, you can also unlock savings in shipping and handling down the line.

Shipping and Logistics Savings

Shipping costs are heavily influenced by material weight, especially for bulk orders or large-format prints. Shipping companies calculate charges based on either actual weight or dimensional weight – whichever is greater. For instance, in March 2025, DCL Logistics client Willow managed to cut shipping and labor costs by 50% by rethinking their packaging strategy and focusing on weight reduction.

Lighter materials also lead to lower import tariffs and create savings across the supply chain by reducing both product and shipping costs. James Scott from Printingblue highlights the importance of this approach:

"Custom product packaging, when designed correctly, can significantly lower storage, freight, and import costs. By optimizing the size and weight of each shipment, businesses can protect their margins, stay competitive, and operate more efficiently."

Packaging costs alone often make up at least 10% of a product’s retail price. Small reductions in weight can lead to big savings. For example, flexible packaging costs between $0.25–$0.75 per unit, while rigid boxes range from $8.50–$10.00 per unit when ordering 5,000–25,000 units. These savings in logistics contribute directly to smoother operations and better cost control.

Handling and Storage Efficiency

Lighter materials also improve efficiency when it comes to handling and storage. Employees can move lighter materials more quickly and with less effort, boosting productivity and reducing the risk of workplace injuries. Storage becomes simpler and more cost-effective, as lighter materials require less heavy-duty shelving and infrastructure. This allows businesses to store more units in the same space without exceeding weight limits.

Additionally, lightweight materials make internal transportation easier, enabling workers to carry larger quantities per trip. They also integrate seamlessly with automated systems, reducing the need for manual labor and further cutting labor costs. These advantages make lighter materials a practical choice for improving overall operational efficiency.

Benefits of Lightweight Materials for Printing

Using lightweight materials in printing offers a trio of advantages: reduced waste, lower costs, and preserved print quality. By selecting the right materials, you can achieve operational efficiencies while maintaining high standards in production.

Cost Reduction and Waste Minimization

Lightweight materials aren’t just about saving on raw materials – they can significantly cut manufacturing costs. For instance, reducing material weight by 10% can lower manufacturing expenses by 4%. Considering that nearly 44.3% of manufacturing costs stem from materials, even modest weight reductions can lead to noticeable financial savings.

This concept, often called "lightweighting", involves using fewer materials without compromising functionality. For example, swapping a heavier, lower-grade board for a stronger, lightweight option can lead to up to a 20% reduction in weight. One company achieved an 8% weight reduction by switching to a lighter cartonboard, saving 2.2 tons (about 4,850 lbs) of material, reducing transport needs by eight pallets, and cutting waste by 120 kg (approximately 265 lbs).

"Switching to a packaging material with lower grammage, but higher strength and stiffness, will save you money from every shipment down to every last package and single sheet." – Billerud

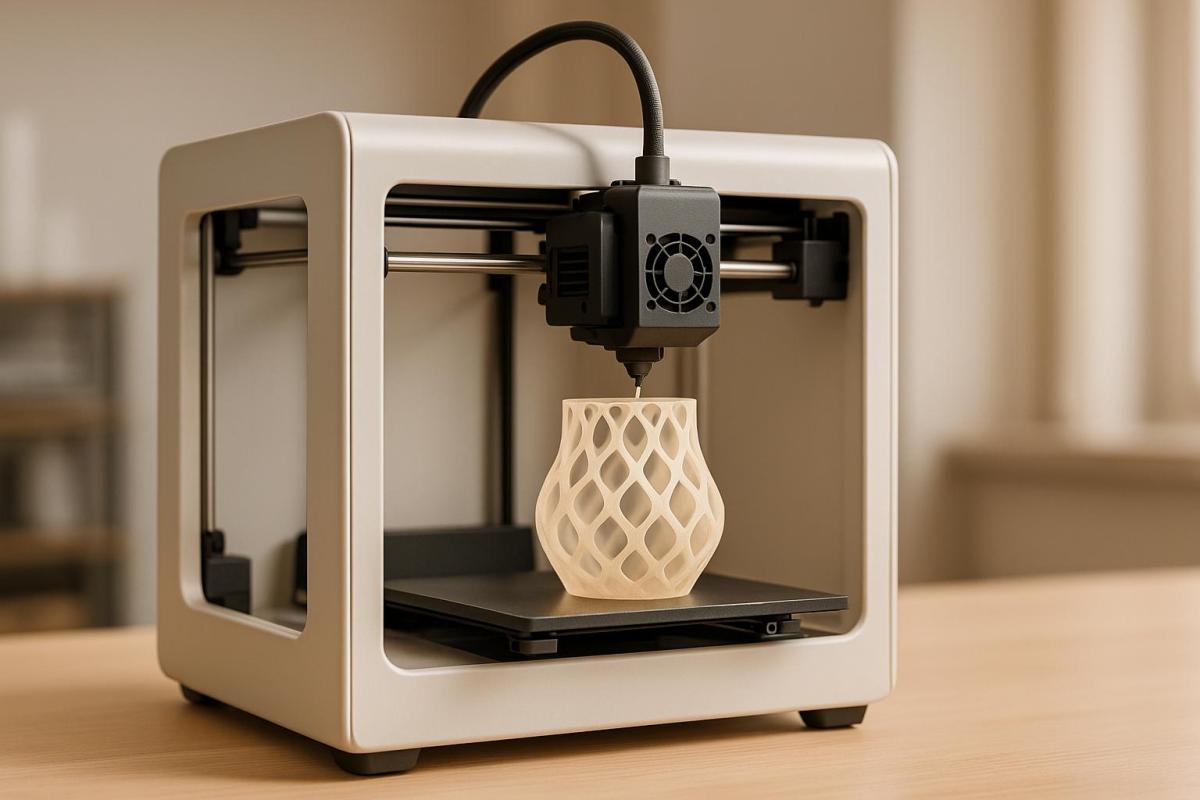

Advanced manufacturing methods like 3D printing amplify these savings. Unlike traditional methods that often waste material, 3D printing uses only what’s needed, reducing waste and material costs by nearly 90%. These efficiencies not only save money but also pave the way for more sustainable practices.

Environmental Benefits

Lightweight materials also contribute to greener operations. Lighter shipments consume less fuel, cutting carbon emissions and reducing energy use during production. Beyond transportation, lightweight materials often support better recycling practices. For example, Henkel redesigned a spray pump to use less plastic, saving more than 450 metric tons (roughly 992,000 lbs) of plastic annually.

JawsTec offers another compelling example. By optimizing their selective laser sintering process, the company eliminated 30% waste in thermoplastic powder usage, achieving full powder utilization. As Oscar Klassen, Co-Founder & CEO of JawsTec, explains:

"The QLS 230 printers give us the ability to use end-of-life powder from other SLS and MJF machines to produce high-quality parts while eliminating powder waste. On top of the operational sustainability, the smaller build volume of the QLS 230 allows for a much shorter build cycle and cooling cycle with zero negative effect on part accuracy or surface quality." – Oscar Klassen, Co-Founder & CEO, JawsTec

These sustainable practices don’t just help the planet – they also align with operational goals, all while maintaining the integrity of the final product.

Maintaining Print Quality

While cost and environmental benefits are essential, print quality remains a top priority. Lightweight materials, when chosen carefully, can deliver excellent results without compromising performance.

Modern lightweight materials are designed for precision and reliability. In printing, these materials allow for significant weight reductions while maintaining output quality. For example, advanced 3D printing techniques can optimize material structures for better performance. A real-world example is the Boeing 787, where a 20% weight reduction led to improved fuel efficiency, showcasing the broader advantages of lightweighting.

In printing applications, lighter materials also improve equipment handling. They move more smoothly through machinery, reducing jams and wear and tear, which ensures consistent print quality and fewer production disruptions. This smooth processing, combined with the ability to meet specific weight requirements, allows engineers to design products that not only perform well but also integrate additional functionality.

Selecting the Right Lightweight Materials

Picking the right lightweight materials is all about finding the sweet spot between cost and performance. This decision plays a big role in supporting the cost-saving strategies we’ve discussed earlier. The materials you choose directly affect print quality, durability, and the overall success of your project. Understanding your options is key to making informed choices that balance both budget and performance.

Common Lightweight Materials in Printing

The printing world offers a variety of lightweight materials, each suited to specific needs. Here are some common categories:

- Paper and cardstock: Ideal for everyday documents and premium items like business cards or postcards.

- Plastic substrates: Materials like PVC, polystyrene, and polyester are durable and can handle moisture and UV exposure, making them perfect for outdoor use.

- Metal substrates: Options like aluminum, steel, and brass deliver durability and a polished look, great for signage projects.

- Fabric materials: Choices like cotton, polyester, silk, and canvas provide a range of textures while keeping things lightweight.

- Eco-friendly alternatives: These materials combine lightweight properties with environmentally conscious production methods.

Once you’ve identified possible materials, it’s time to evaluate them against the specific needs of your project.

Factors to Consider

Choosing the right material means weighing several factors to ensure it meets both quality and budget requirements.

- Strength and durability: Think about how long the material needs to last and the conditions it will face, such as exposure to moisture or sunlight.

- Compatibility with printing technology: Not all materials work with every printing method. Make sure your choice aligns with your printing process, whether it’s offset, digital, or screen printing.

- Paper weight and thickness: Heavier materials feel more premium, but thinner options are lighter and can cut down on shipping costs.

- Paper finish: Gloss, matte, satin, or uncoated finishes can dramatically change the final look of your project. Match the finish to your design goals.

- Color and whiteness: The substrate’s color can influence how your design appears, so consider how it interacts with your chosen colors.

Here’s a quick comparison of some common materials to help with decision-making:

| Material Type | Strength | Flexibility | Durability | Heat Resistance | Cost |

|---|---|---|---|---|---|

| Lightweight Paper | Moderate | Low | Good | Low | Low |

| Cardstock | High | Moderate | Good | Moderate | Moderate |

| Plastic (PVC/Polyester) | High | Moderate | Excellent | Moderate | Moderate |

| Metal (Aluminum) | High | Low | High | High | High |

| Fabric (Polyester) | Low | High | Moderate | Low | Moderate |

Material and Process Compatibility

The next step is ensuring your chosen material works seamlessly with your printing process. Mismatched materials and processes can lead to issues like poor ink adhesion or deformation.

- Check that the ink and substrate are compatible in terms of surface tension and chemical properties.

- Make sure the ink’s drying method aligns with the heat or chemical resistance of the material to avoid damage.

- Adjust printing parameters as needed, such as temperature, print speed, or pressure, to suit the substrate’s characteristics.

- Some materials may require pre-treatment or special ink formulas to improve compatibility.

Don’t forget to consider the quantity of materials needed, as bulk orders can impact per-unit costs and availability. For outdoor projects, it’s worth checking if weather-resistant coatings or laminates are necessary to maintain durability and appearance.

Finally, testing prototypes with your selected materials can help you fine-tune the process and identify potential savings before jumping into full production.

sbb-itb-ce53437

Cost Optimization Strategies with Lightweight Materials

Once you’ve selected lightweight materials, the next step is to maximize cost efficiency without compromising quality. By implementing targeted strategies, you can ensure that every aspect of your project aligns to reduce expenses while maintaining performance. These approaches build on the interplay between material weight and cost, creating a harmonious process that prioritizes savings.

Optimize Material Thickness

One of the simplest ways to save money is by determining the ideal material thickness for your project. The goal is to use the least amount of material necessary while still meeting functional requirements. Techniques like hollowed sections, structural ribs, and efficient infill patterns (e.g., honeycomb or triangular designs) help reduce material usage while preserving strength. For 3D printing, adding escape holes in hollowed sections prevents trapped powder or resin during post-processing, further improving efficiency. Generative design software also offers a powerful solution, automatically distributing material only where it’s structurally needed.

Use Efficient Printing Processes

Your choice of printing process can significantly impact production costs. For smaller runs, digital printing offers a cost-effective and fast solution. For larger volumes, methods like LED UV printing – which uses UV lights to instantly dry ink – or flexography, ideal for lightweight substrates like thin films or light cardboard, provide efficient and scalable options.

When it comes to specific needs, inkjet printing delivers high-quality results but comes with a higher per-print cost. On the other hand, laser printing is faster but requires a more expensive setup. In the realm of 3D printing, affordable methods like Fused Deposition Modeling (FDM) are popular for general use, whereas Selective Laser Sintering (SLS) is preferred for creating precise and durable components for demanding applications. Matching the right printing process with your lightweight material strategy can lead to significant savings.

Minimize Material Waste

Reducing waste is another key to controlling costs. Start by optimizing print layouts to minimize offcuts, adopting minimalist designs to lower ink use, and implementing quality control measures early in production to catch defects before they turn into waste. Lean manufacturing principles can also drive continuous improvements in waste reduction.

For example, studies show that 45% of office-printed paper is discarded by the end of the day. Planning realistic print runs can prevent unnecessary waste, and recycling programs play a dual role in cost control and environmental responsibility. Yet, only 20–30% of toner waste is recycled globally. Conducting regular waste audits can help identify problem areas and set actionable goals for improvement.

"Sustainable print design is all about creating print materials in a way that minimizes environmental impact." – Greg Barber

Simple adjustments, like using minimalist designs and eco-friendly fonts, can also reduce ink usage while maintaining a professional look.

If you’re looking for expert assistance in applying these strategies to your projects, consider reaching out to Miro Printing & Graphics Inc. (https://bergencountyprinters.com). Based in Hackensack, NJ, they offer full-service printing solutions tailored to your needs.

Lightweight vs. Heavy Materials: A Comparison

When it comes to managing costs effectively, understanding the pros and cons of lightweight versus heavy materials is essential. Your choice should align with cost considerations, quality standards, and environmental goals. Each material type offers unique benefits and drawbacks that can influence overall expenses, print outcomes, and ecological impact. Here’s a breakdown to help you decide which is best for your needs.

Material costs make up more than 40% of manufacturing expenses. Opting for lightweight materials can reduce manufacturing costs by 4% for every 10% reduction in weight, as these materials often weigh up to 50% less than their metal counterparts. They also consume less energy during production, which helps minimize the carbon footprint.

However, the decision isn’t always straightforward. For instance, lightweight paper (20–24 lb) is cost-effective and works well for high-volume printing, but it may lead to ink spreading or smudging. On the other hand, heavier paper (32–80 lb) offers sharper prints and greater durability, making it ideal for premium projects. Lightweight paper tends to absorb more ink, resulting in a softer look, while heavier paper retains ink better, producing sharper and more vibrant results.

Comparison Table

Here’s a quick look at how lightweight and heavy materials stack up:

| Feature | Lightweight Materials | Heavy Materials |

|---|---|---|

| Cost | Lower costs due to reduced raw material usage | Higher costs because of greater material volume |

| Manufacturing Costs | 4% savings for every 10% weight reduction | Higher production costs tied to material volume |

| Shipping Expenses | Cheaper shipping due to lighter weight and compact packaging | Higher shipping costs, sometimes with oversized surcharges |

| Print Quality | Prone to ink spreading or smudging on very light papers | Produces sharper, more vibrant prints with better ink retention |

| Durability | Less durable, suited for short-term or disposable uses | More durable, better for long-term or frequent handling |

| Environmental Impact | Lower carbon footprint and waste | Higher impact due to increased material use |

| Storage Requirements | Easier to store and handle | Requires more storage space and sturdier handling |

| Professional Appearance | Best for everyday printing and mass distribution | Offers a high-end feel, great for business cards or marketing materials |

Ultimately, the choice boils down to your project goals, budget, and quality expectations. Lightweight materials are a smart pick for high-volume, cost-driven tasks, while heavy materials are worth the investment for projects that need to stand out or withstand frequent use.

Conclusion: Maximizing Savings with Lightweight Materials

Lightweight materials offer a smart way to cut costs while aligning with sustainability goals. A 10% reduction in material weight can lower manufacturing costs by 4%, making these materials a practical choice for managing expenses.

Success hinges on selecting the right materials and fine-tuning your processes. Focus on reducing material thickness where feasible without sacrificing strength, adopt efficient printing techniques that minimize waste, and ensure the materials you choose work seamlessly with your printing methods.

Maintaining quality control is crucial when using lightweight materials. Structured inspections – before, during, and after printing – can help you avoid expensive reprints and delays. These measures not only improve operational efficiency but also complement the environmental benefits of lightweight materials.

The environmental perks bring even more value. With consumers willing to pay 9.7% more for products made sustainably, lightweight materials can help your business stay competitive by meeting market expectations while keeping costs in check.

To fully capitalize on these advantages, working with experienced printing professionals can make a big difference. Miro Printing & Graphics Inc. provides expert guidance on material selection, process optimization, and quality control, helping you transition to lightweight materials while achieving exceptional results.

FAQs

How can using lightweight materials help lower shipping and logistics costs in printing?

Using lightweight materials in printing can make a big difference when it comes to shipping and logistics expenses. By reducing the overall weight and size of packages, you can cut down on transportation fees, as shipping providers often base their rates on these factors. Plus, lighter materials allow you to fit more products on each pallet or truckload, boosting efficiency and trimming freight costs.

Another advantage of lightweight materials is better space optimization during transit. This not only reduces handling expenses but also simplifies logistics. On top of the financial perks, using lighter materials supports more environmentally friendly shipping practices by cutting fuel usage and lowering emissions during transport.

What should I consider when choosing lightweight materials for printing projects?

When choosing lightweight materials for printing, prioritize durability, visual appeal, and cost-effectiveness. Opting for lighter materials can help cut down on shipping and handling costs while still delivering polished, professional results.

Think about the material’s flexibility, its ability to resist wear and tear, and its impact on the environment. It’s also important to match the material to your project’s unique demands – whether that means withstanding harsh weather or enduring frequent use. Selecting the right material ensures you can manage costs without sacrificing quality or functionality.

How can businesses use lightweight materials to reduce printing costs without sacrificing quality?

Using lightweight materials is a smart way to cut printing costs, but keeping the quality intact takes some careful planning. The first step is choosing the right lightweight materials – ones that are both durable and flexible. For example, lightweight PLA (LW-PLA) is a solid choice, offering reduced weight without sacrificing strength.

Next, it’s crucial to fine-tune your print settings to suit the material. Adjust settings like layer height, print speed, and temperature to get the best possible outcome. Regular printer calibration and prepping the print surface properly are also key to achieving consistent, high-quality results.

Finally, make sure to work with high-resolution design files and handle the materials carefully to avoid any flaws. By focusing on these details, businesses can trim costs with lightweight materials while still producing top-notch prints.

Related posts

- How to Choose Cost-Effective Printing Materials

- Cost Analysis: Traditional vs. Alternative Materials

- Cost-Saving Tips for Sustainable Paper Choices

- How to Save on Print Marketing Costs

https://app.seobotai.com/banner/banner.js?id=6854a8045559d477e75fa9c9