When deciding how to protect printed materials, lamination and coating are two popular options. Both methods shield prints, but they differ in durability, cost, and application.

- Lamination applies a plastic film for strong protection against moisture, wear, and heavy handling. It’s ideal for menus, ID cards, and outdoor signage.

- Coating uses a liquid layer that hardens directly on the paper. It offers a sleek finish with moderate protection, making it suitable for brochures, business cards, and indoor marketing materials.

Each method has its strengths, so your choice depends on factors like exposure to elements, handling frequency, budget, and desired appearance.

Quick Comparison

| Feature | Lamination | Coating |

|---|---|---|

| Moisture Protection | High (waterproof) | Moderate |

| Durability | Strong (resists tears, wear) | Moderate (scratches, smudges) |

| Thickness Added | Noticeable | Minimal |

| Flexibility | Limited | High |

| Cost | Higher | Lower |

| Best For | Outdoor use, heavy handling | Indoor use, light handling |

For long-lasting durability in harsh conditions, choose lamination. For a cost-effective solution with a polished look, coating is the way to go.

UV Coating vs Lamination

What Is Lamination

Lamination is a finishing technique that involves bonding a thin plastic film to printed materials. This film acts as a protective layer, shielding documents, photos, or marketing items from wear, moisture, and frequent handling. Once applied, the film becomes a permanent part of the material.

This method is widely used in commercial printing because it helps extend the life of printed items. Let’s take a closer look at how the process works.

How Lamination Works

Lamination relies on heat and pressure to activate an adhesive on the plastic film. During the process, printed materials pass through heated rollers (typically between 180°F and 300°F), which activate the adhesive and create a strong bond between the film and the paper.

There are two primary methods for applying lamination:

- Hot lamination: This uses heat to activate the adhesive and is the most common option for commercial purposes.

- Cold lamination: Instead of heat, this method relies on pressure-sensitive adhesives, making it ideal for heat-sensitive materials like photographs.

Laminating films come in various thicknesses, usually ranging from 1.5 to 10 mils (0.0015 to 0.01 inches). Thicker films offer greater rigidity and protection, while thinner films are more flexible and budget-friendly for basic needs.

Now that we’ve covered the process, let’s dive into the different finishes and their uses.

Lamination Types and Uses

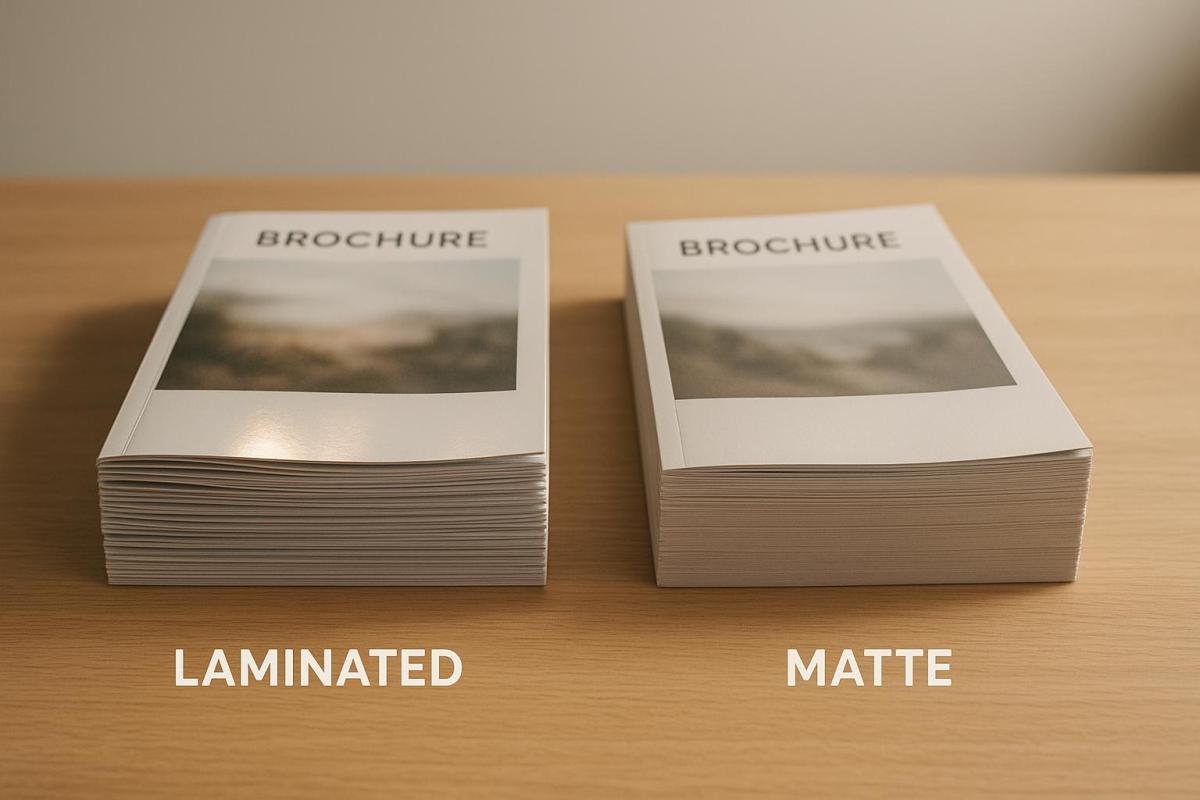

- Gloss lamination: This finish provides a shiny, reflective surface that enhances color vibrancy, making it perfect for marketing materials like brochures, book covers, and presentation folders. It also offers excellent moisture protection.

- Matte lamination: With a smooth, non-reflective finish, matte lamination reduces glare and gives a polished, professional look. It’s a popular choice for business cards, menus, and educational materials, especially where readability is key. Plus, it hides fingerprints better than gloss finishes.

- Soft-touch lamination: This finish adds a velvety, luxury feel to printed materials while still offering durability. It’s a go-to for high-end brochures, premium product packaging, and book covers. The soft texture also provides a better grip, making items easier to handle.

Lamination is commonly used for ID cards and badges, as it ensures durability and adds security. Restaurant menus benefit from its spill resistance and easy cleaning, while outdoor signage gains protection from UV rays and weather. In classrooms, educational materials like charts and guides are laminated to withstand frequent handling.

This process is ideal for materials that need to endure heavy use or exposure to the elements, combining durability with a polished, professional appearance.

What Is Coating

Coating involves applying a liquid solution that hardens into a protective layer over printed materials, enhancing both their appearance and durability without adding noticeable thickness. This makes it particularly effective for items that require flexibility, such as brochures, direct mail pieces, and multi-page documents. Additionally, many coatings are designed to be recyclable and produce lower levels of volatile organic compounds (VOCs), offering environmental benefits.

Let’s take a closer look at how this process turns a liquid into a durable finish.

How Coating Works

The coating process begins with a liquid solution that penetrates the paper fibers and then cures – using heat, air, or ultraviolet (UV) light – into a protective layer. The curing method depends on the type of coating being used.

- UV Coating: This method uses ultraviolet light to cure the liquid almost instantly, typically within 0.1 to 0.3 seconds. The UV light triggers a chemical reaction that solidifies the coating into a durable surface, allowing for immediate handling and further processing.

- Aqueous Coating: This water-based solution dries through heat and air evaporation. Known for its environmentally friendly properties, it emits low levels of VOCs and is recyclable.

Both methods bond with the paper, becoming part of the material rather than sitting on top of it. The performance and applications of these coatings depend on their specific properties, as explained below.

Coating Types and Uses

Each type of coating serves different purposes, offering distinct benefits and limitations.

- UV Coating: Known for its exceptional resistance to scratches, moisture, and UV damage, this coating is available in finishes like high-gloss, matte, satin, and textured. Recognized by the EPA as a "Best Available Control Technology" (BACT), UV coatings help reduce VOCs, CO₂ emissions, and energy use. Tests have shown that UV-coated materials retain their quality even after three years of use. This makes it ideal for business cards, catalogs, retail packaging, and food packaging – particularly for items subjected to frequent handling or moisture exposure. However, UV coatings are less flexible and may crack when folded, limiting their use for materials that require creasing.

- Aqueous Coating: This eco-friendly option provides protection against fingerprints and minor abrasions. Its standout feature is flexibility – aqueous coatings remain pliable even after drying, making them perfect for brochures, folded menus, and direct mail pieces that need to be scored or folded. Additionally, they are biodegradable and can be recycled without requiring separation from the paper. While not as durable as UV coatings, they still offer sufficient protection for many applications.

| Coating Type | Best Applications | Benefits | Limitations |

|---|---|---|---|

| UV Coating | Business cards, retail packaging, catalogs, food packaging | Instant curing, high durability, multiple finish options | May crack on folds, higher cost |

| Aqueous Coating | Brochures, folded menus, direct mail, multi-page documents | Flexible, eco-friendly, cost-effective | Less durable than UV coating |

Choosing between UV and aqueous coating depends on factors like durability needs, budget, and whether the material will be folded or creased. Each option has its strengths, tailored to specific use cases.

sbb-itb-ce53437

Protection and Durability Comparison

When deciding between lamination and coating, it’s important to weigh their protective qualities to determine which finish aligns best with your project’s needs. Each option has its strengths, depending on how much protection is required and the purpose of your printed materials.

Protection Levels

Lamination wraps your prints in a plastic film that shields them from moisture, tears, and heavy wear. In contrast, coating bonds directly with the paper, offering resistance to fingerprints, light scratches, and minor moisture exposure.

If your project involves items like outdoor signage, restaurant menus, or materials that are frequently handled, lamination tends to provide a more durable solution. Coating, on the other hand, works well for print pieces that need a more natural paper feel and flexibility, such as brochures or marketing materials used in controlled settings. Let’s explore how these finishes handle environmental challenges.

Weather and UV Resistance

Both lamination and coating offer UV protection, but lamination provides stronger moisture resistance, making it better suited for outdoor use. The plastic film not only blocks moisture but also minimizes UV penetration, creating a robust waterproof barrier. Coatings, while effective at preventing color fading, offer limited moisture protection.

Temperature changes also impact these finishes differently. Laminated materials may become less flexible in colder conditions and expand slightly in heat, though the protective layer remains intact. Coated materials, however, retain their flexibility across temperature ranges but may lose durability if exposed to extreme conditions over time.

Side-by-Side Comparison

Here’s a quick breakdown of the key differences between lamination and coating:

| Feature | Lamination | Coating |

|---|---|---|

| Moisture Protection | Fully waterproof | Light moisture resistance |

| Resistance to Physical Damage | Excellent for tears and heavy use | Moderate protection against scratches and wear |

| UV Resistance | Strong with UV-resistant films | Effective, but less moisture protection |

| Flexibility | Can become rigid in cold or crack with sharp folds | Maintains flexibility |

| Thickness Added | Noticeable bulk | Minimal change to paper feel |

| Environmental Impact | Can complicate recycling | Often easier to recycle |

| Cost | Higher due to materials and labor | More budget-friendly |

| Processing Time | Takes longer due to additional steps | Quicker with UV curing |

| Best Applications | Outdoor signs, ID cards, high-use materials | Brochures, business cards, marketing materials |

| Longevity | Ideal for heavy use and long-term durability | Better for lighter, short-term use |

Ultimately, your choice between lamination and coating will depend on the level of protection you need, your budget, and how the materials will be used. Each option has its place, so consider these factors carefully to make the best decision for your project.

How to Choose the Right Finish

When deciding on the best finish for your project, it all comes down to specific needs like how often the material will be handled, exposure to the elements, budget, desired look, and production timelines.

What to Consider

Handling Frequency plays a big role. If your materials will be touched often – think restaurant menus, ID cards, or reference guides – lamination is your go-to. The protective plastic film shields against oils, smudges, and repeated folding, keeping everything intact. On the other hand, coating works well for items like brochures or flyers that won’t see heavy use.

Environmental Exposure is another key factor. For outdoor materials, such as signs, parking permits, or event banners, lamination provides excellent waterproofing and UV protection. Indoor items like business cards, presentation folders, or marketing brochures can rely on coating for lighter protection since they’re less exposed to harsh conditions.

Budget Constraints are important to weigh. Coating is generally more affordable because it involves less complex processes and materials. It’s a great choice for large print runs where durability isn’t the top priority, offering a polished look without breaking the bank. However, keep in mind that materials needing frequent replacement due to damage may end up costing more in the long run compared to investing in lamination upfront.

Appearance Preferences depend on how you want your project to look and feel. Lamination adds a glossy shine and thickness, giving off a high-end vibe, but it can make writing on the surface difficult. Coating, on the other hand, maintains the paper’s natural texture while subtly enhancing colors. Your choice depends on whether you need lamination’s durability and shine or coating’s understated, flexible finish.

Timeline Requirements can also influence your decision. UV coating cures quickly, making it ideal for tight deadlines. Lamination, while offering more durability, involves extra steps that can extend production time.

Custom Solutions with Miro Printing & Graphics Inc.

Miro Printing & Graphics Inc. specializes in both lamination and coating finishes, helping businesses make the right choice based on their unique needs. With in-house bindery services, they offer a wide range of finishing options tailored to your project’s requirements and budget.

Their team carefully evaluates each project, considering factors like usage, exposure, and longevity, to recommend the most effective finish. They’ve worked with a variety of industries, from healthcare facilities needing durable signage to restaurants looking for waterproof menus.

Thanks to their advanced digital and offset printing capabilities, Miro Printing & Graphics Inc. ensures a seamless process from start to finish. Whether you’re creating business cards that benefit from coating’s sleek look or outdoor banners needing lamination’s weatherproofing, their expertise ensures consistent quality.

For projects with unique needs – like die-cut designs, specialty materials, or high-volume production – Miro Printing & Graphics Inc. adapts their finishing methods to meet your goals. They help determine when investing more in lamination makes sense for long-term durability versus choosing coating for an affordable, quicker option. Their approach ensures your finish aligns with both immediate and future project demands.

Conclusion

Choosing between lamination and coating comes down to your specific needs – how much protection you require, how often the material will be used, and your budget. Lamination stands out for its durability and ability to shield materials from weather and frequent handling, making it a great choice for items like menus or outdoor signage. On the other hand, coating offers a polished look with moderate protection, making it a cost-effective option for lighter, indoor use.

The key is to align the finish with the material’s purpose and expected lifespan. Lamination is perfect for items exposed to moisture or heavy handling, while coating works well for enhancing the appearance of materials used in less demanding environments.

At Miro Printing & Graphics Inc., we’re here to help you make the right choice. Our In-House Bindery services provide a wide range of finishing options, from durable laminated signs to various coating techniques. With extensive Post-Press & Bindery services, including cutting, creasing, folding, and binding, we deliver customized solutions tailored to your project’s needs. Whether you prioritize lamination’s toughness or coating’s sleek finish, our expert team ensures top-quality results that fit your budget.

FAQs

How do I decide between lamination and coating for my printed materials?

When choosing between lamination and coating, think about how much protection and durability your project needs. Lamination adds a thicker, sturdy layer that shields against water, UV rays, and scratches. This makes it a solid option for items like menus, business cards, or other materials that get handled a lot. Plus, it offers a sleek, polished finish that holds up over time.

Coating, on the other hand, is a thinner, more budget-friendly solution. Options like UV or liquid coatings provide decent protection while enhancing the look of your prints with finishes like glossy, matte, or soft-touch. Coatings work well for short-term projects or materials where appearance and fast production are key.

Your decision should come down to factors like how the material will be used, how durable it needs to be, your budget, and the overall look you want for your printed pieces.

What’s the difference in environmental impact between lamination and coating?

Lamination tends to have a greater environmental impact than coating, largely because most laminates are made from non-biodegradable plastics like PET. These materials can take hundreds of years to decompose and are a major contributor to plastic pollution. On the other hand, coatings – particularly water-based ones – are often seen as a more eco-friendly option. They are typically biodegradable and easier to recycle.

While there are newer laminates made from sustainable, recyclable, or biodegradable materials, traditional plastic laminates still present significant environmental challenges. In comparison, coatings generally leave a lighter environmental footprint, making them a more environmentally conscious choice for many printing applications.

When should you choose lamination over coating, or vice versa?

Lamination stands out as the go-to option when you need long-lasting durability and top-tier protection. It’s perfect for items like packaging, ID cards, or materials that will endure frequent handling, spills, or even exposure to UV light. Beyond its protective qualities, lamination adds a polished, professional touch that elevates the look and feel of your project.

Coating, on the other hand, shines in projects that demand a fast turnaround, enhanced color vibrancy, or specific finishes such as gloss or matte. It’s an excellent choice for short-term or less demanding applications, offering an affordable way to protect your materials while keeping design and production flexible.

Related Blog Posts

- UV Printing vs. Lamination: Which Protects Better?

- Ultimate Guide to Glossy Coatings for Printing Projects

- Ultimate Guide to Varnish Coatings in Printing

- Matte vs Gloss Lamination: Key Differences

https://app.seobotai.com/banner/banner.js?id=68c78f53119e7220d7f06356