Fogra certification is a trusted standard in the printing industry, proving a provider’s ability to deliver consistent, high-quality, and color-accurate results. Recognized globally, it ensures compliance with ISO standards like ISO 12647 (process control) and ISO/TS 15311 (digital printing). For print professionals, this certification builds credibility, improves workflows, and attracts clients who prioritize precision.

Key Steps to Achieve Fogra Certification:

- Technical Knowledge: Master color management, ISO standards, and PDF/X workflows.

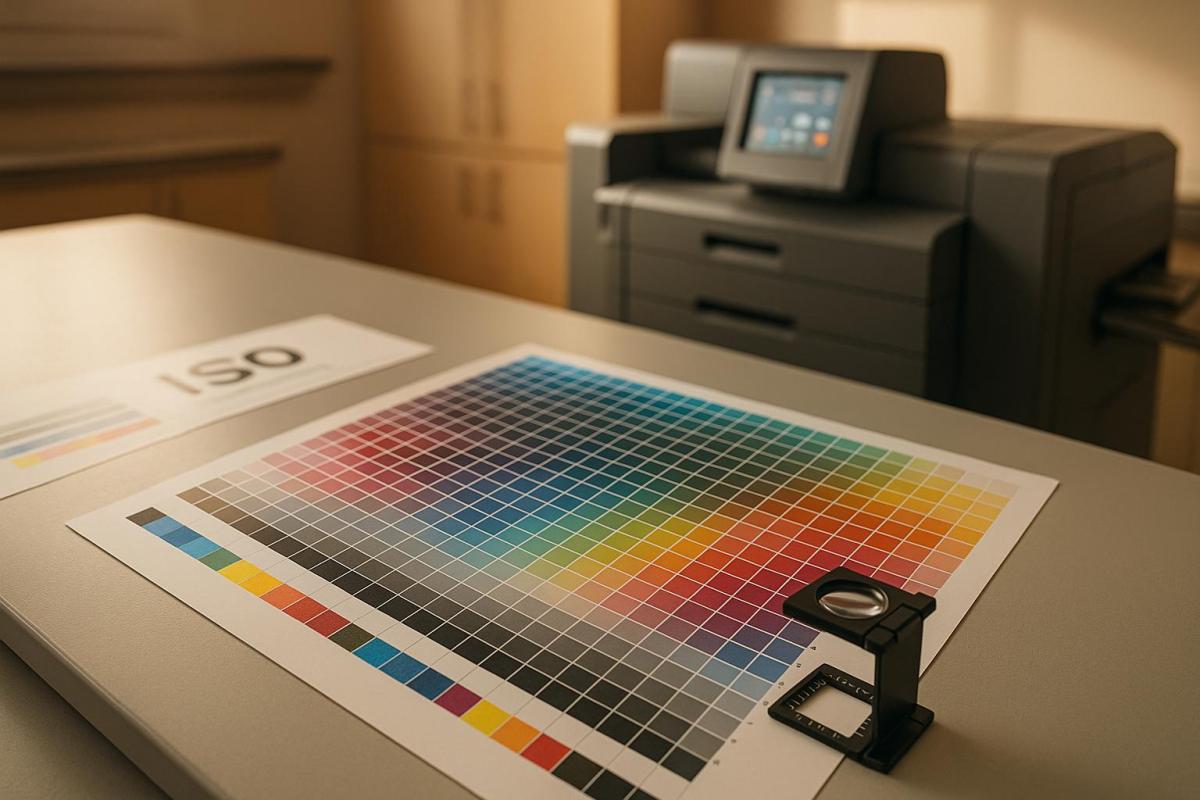

- Equipment Requirements: Use calibrated tools like spectrophotometers, Fogra-certified proofing systems, and ISO 3664-compliant lighting.

- Training: Enroll in Fogra-approved programs to gain necessary skills.

- Application Process: Prepare documentation, conduct internal reviews, and submit materials to Fogra.

- Audit & Examination: Undergo an on-site audit and demonstrate compliance with Fogra’s standards.

Benefits:

Certified businesses experience improved efficiency, reduced waste, and better print quality. Certification is valid for two years, with a renewal process ensuring continued adherence to standards.

Whether you’re a small print shop or a large operation, Fogra certification signals a commitment to precision and quality in a competitive industry.

de FOGRA 39 a FOGRA 51. APRENDE, CONVIERTE y MIGRA a la nueva ISO 12647 de IMPRESIÓN

Requirements for Fogra Certification

To achieve Fogra certification, print professionals must meet specific technical and equipment-related criteria. Below, we break down the essential requirements.

Required Technical Knowledge and Skills

A strong understanding of color management is a must for anyone pursuing Fogra certification. This includes expertise in color spaces, profiling techniques, and calibration processes that ensure consistent and accurate color reproduction across various devices and materials. These skills are vital to meet Fogra’s high standards for color consistency.

Familiarity with ISO standards is another key requirement. For those in offset printing, ISO 12647 is the standard to master, while digital printing professionals need to be well-versed in ISO/TS 15311. These standards serve as the foundation for Fogra’s certification guidelines, covering everything from quality control to process management.

Another critical area is print data preparation. Professionals must be skilled in creating and reviewing PDF/X-compliant files, often using preflighting tools. The Altona Test Suite, widely used for PDF validation, is a common part of Fogra certification assessments, making familiarity with this tool highly beneficial.

For some certification programs, like the Fogra PSD Digital Print Professional, candidates are required to have prior technical experience and a background in color management before enrolling. This ensures participants can fully engage with the training and meet certification standards.

Equipment and Process Requirements

Beyond technical skills, achieving Fogra certification requires the right equipment and standardized workflows.

A Fogra-certified proofing system is mandatory. This system must consistently deliver accurate color reproduction and undergo regular calibration to maintain performance.

Professionals also need calibrated spectrophotometers for precise color measurements throughout the production process.

On the software side, tools for color transformation and PDF/X preflighting are crucial to support standardized workflows. Additionally, digital printing operations must use a licensed Fogra MediaWedge CMYK to evaluate color accuracy and maintain production consistency.

Workspaces must include ISO 3664-compliant norm light booths. These controlled lighting environments ensure accurate color evaluations, regardless of ambient lighting conditions, by adhering to standardized light conditions.

Standardized PDF/X workflows and detailed process documentation are also essential. This includes creating internal quality control checklists in line with Fogra standards and conducting regular audits to maintain compliance.

For digital printing certification, the entire workflow – from file preparation to final output – must be fully auditable and repeatable. Clear documentation of color management practices, process stability checks, and quality control measures is crucial for meeting Fogra’s rigorous audit requirements.

Take, for example, a print shop like Miro Printing & Graphics Inc., which offers digital, offset, and large-format printing services. To achieve Fogra certification, they would need to implement all these equipment and process standards across their operations. While this requires an investment in tools and documentation, it ultimately enhances efficiency and customer satisfaction.

How to Apply for Fogra Certification

Once your facility meets the necessary technical and equipment requirements, the next step is to navigate the application process. This involves targeted training and compiling thorough documentation to demonstrate your readiness.

Finding and Enrolling in Fogra-Approved Training

Fogra Academy and Web Academy are the go-to platforms for certification training. These programs cover essential areas like color management, print quality control, workflow standardization, and adherence to ISO standards such as ISO 12647 and ISO 15311. For digital print professionals, Fogra offers fully online certification programs that are self-paced – perfect for busy print shops looking to minimize downtime. However, a solid understanding of color management basics is highly recommended before starting these courses.

In addition to Fogra’s own platforms, regional partners and authorized trainers also provide approved courses. For instance, APTEC offers both onsite and virtual sessions tailored to the PSD Digital Print Professional certification. To find the right training, visit Fogra’s official website. You can explore courses by skill level, preferred learning format, and the specific certification you’re aiming to achieve.

After completing your training, the next step is to gather the necessary documentation and submit your application.

Completing the Application Process

Before you formally apply, conduct an internal review of your processes and equipment to ensure they align with Fogra standards. This includes compiling detailed documentation, such as process descriptions, quality control checklists, and records of staff training, to support your application.

Additionally, verify that your equipment is properly calibrated and that your software meets Fogra’s requirements. Some certifications may also require you to demonstrate compliance with ISO 3664 lighting conditions and PDF/X-ready preflighting capabilities.

Once all documentation is prepared, submit your training certificates and supporting materials directly to Fogra or through an authorized partner. Be sure to check Fogra’s website for up-to-date submission guidelines, as fees and procedures can vary depending on the certification type and your location.

Morgan Manning of Heidelberg USA, Inc. maintained Fogra Digital Print Professional certification in 2016. Manning utilized the certification’s principles to educate clients and enhance both digital and offset workflows. According to Manning, Fogra’s guidance was invaluable in addressing technical challenges.

For instance, a print shop like Miro Printing & Graphics Inc. in Hackensack, NJ, could enroll key staff in Fogra-approved training programs and upgrade their equipment to meet Fogra standards before applying. Achieving certification not only reinforces their reputation for quality but also attracts clients who prioritize certified color accuracy and process control.

The timeline for certification varies depending on your facility’s preparation and the type of certification you’re pursuing. Key steps include completing training, preparing and submitting documentation, undergoing an on-site audit, and, upon successful review, receiving your certification.

sbb-itb-ce53437

Certification Audit and Examination

Once your application is submitted, Fogra arranges an on-site audit to ensure your print operation meets their stringent standards.

On-Site Audit Process

During the on-site audit, Fogra representatives visit your facility to evaluate your production processes in real-time. This hands-on review allows them to see how your workflow performs under actual working conditions. Key areas of focus include output control, color accuracy, and workflow consistency. Auditors will assess your handling of PDF/X data, verify ISO 3664-compliant lighting, and check that your measurement devices and color management software are functioning correctly. They also ensure compliance with standards such as ISO 12647 and ISO 15311.

Be prepared to provide documented process guidelines, quality control checklists, and audit records for their review.

The audit typically lasts several hours to a full day, depending on the size of your facility and the scope of the certification. During this time, auditors may observe multiple print runs, request test prints using standardized targets like the Fogra MediaWedge, and interview key staff members to gauge their knowledge of color management and workflow practices.

If any non-conformances are found, you’ll receive a detailed report highlighting the issues and suggesting corrective actions. Common problems include inconsistent color reproduction caused by improper calibration or outdated profiles. Once you’ve addressed these issues, you’ll need to provide evidence of the corrections. This audit lays the groundwork for the formal examination, ensuring your operations align with Fogra’s standards.

Examination Standards and Criteria

After clearing the audit, the examination phase evaluates both your facility’s performance and individual expertise. Building on the audit findings, this step confirms your ability to consistently meet Fogra’s rigorous performance benchmarks.

The examination focuses on measurable performance metrics to guarantee high-quality, reliable output. Key areas include color accuracy, print resolution, and the stability of results across multiple production runs. Color fidelity is particularly critical – auditors use standardized test forms and reference targets to compare your printed samples against defined colorimetric values, checking for deviations and ensuring your equipment maintains precise color tolerances.

For professional certification, individuals must pass a written exam that tests both technical knowledge and practical skills. For example, the Digital Print Professional exam requires a minimum score of 50 out of 100 to pass and can be taken online or on-site, depending on the certification type. Topics include output process control, color accuracy assessments, workflow standards, norm lighting conditions, and handling PDF/X data.

| Evaluation Area | Key Criteria | Assessment Method |

|---|---|---|

| Color Fidelity | Accuracy to reference values and consistency | Fogra MediaWedge measurements and colorimetric analysis |

| Print Resolution | Sharpness, detail reproduction, and dot gain control | Visual inspection and densitometric readings |

| Workflow Compliance | Adherence to ISO standards and documented processes | Process observation and review of documentation |

The examination also evaluates your facility’s ability to maintain these standards over time. Auditors will look for evidence of regular internal quality checks, adherence to equipment maintenance schedules, and staff training records – all of which demonstrate a commitment to ongoing quality.

For print shops like Miro Printing & Graphics Inc., earning Fogra certification is a testament to their expertise in color management and workflow excellence. This certification not only enhances credibility but also provides a competitive edge when vying for projects that require certified print partners. It’s a clear signal of dedication to international quality standards, which can help attract clients and secure high-value contracts.

Keeping Your Fogra Certification Current

Achieving Fogra certification is a significant milestone, but maintaining it requires ongoing effort to ensure your operations consistently meet international benchmarks.

Certification Duration and Renewal Process

Fogra certifications, including PSD Digital, are valid for two years, encouraging professionals to stay aligned with evolving standards.

The renewal process starts well before your certification expires. To keep your certified status, you’ll need to submit a renewal application and pay the associated administration fee. For instance, renewing the PSD Digital Print Professional certification costs approximately $450 (HK$3,500/CNY3,500), while the Fogra PSO Professional certification requires around $900 (HK$7,000) for each four-year term.

It’s important to prepare your renewal application in advance. This includes identifying and addressing any compliance gaps, gathering necessary documentation, and scheduling audits. During the renewal process, Fogra representatives conduct re-certification audits to verify that your facility continues to meet the required standards. These audits focus on ongoing compliance rather than starting the certification process anew. Once renewed, maintaining compliance becomes an ongoing priority.

Maintaining Compliance Standards

Renewing your certification is just the beginning. To retain it, your print operation must adhere to Fogra standards consistently throughout the certification period – not just during audits.

Regular internal audits are essential. Use Fogra’s evaluation criteria to assess your operation, including checks for color accuracy with tools like the Fogra MediaWedge CMYK. Verify that your equipment remains calibrated and workflows are documented thoroughly. Scheduling these reviews at regular intervals ensures you stay on track with compliance.

Staff training is another critical element. Enroll key team members in courses offered by Fogra Academy or Web Academy to keep them informed about the latest standards and best practices.

Keep your equipment and software up to date. This includes maintaining valid licenses for tools like the Fogra MediaWedge CMYK, calibrating hand-held measurement devices regularly, and updating color transformation software as needed. Additionally, ensure your lighting conditions meet ISO 3664 standards throughout the certification period.

Documentation plays a pivotal role in demonstrating compliance. Maintain detailed records of internal audits, staff training sessions, equipment calibrations, and any corrective actions taken. Consistently applying Fogra-aligned quality control checklists will help you stay organized and prepared for audits.

Letting your certification lapse can have serious consequences. Losing certification can erode customer confidence and diminish your competitive edge. If your certification expires or standards are not maintained, you may need to restart the entire certification process – a time-consuming and resource-intensive undertaking. Certified print shops signal a strong commitment to quality, which can help secure contracts that require accredited partners.

Finally, stay informed by monitoring updates from Fogra and its partners. These updates often include changes to standards or certification requirements. Implementing any revisions promptly will help ensure continuous compliance and minimize potential gaps.

Conclusion

Achieving Fogra certification is more than just a formal process; it’s a strategic step that can elevate a print business. From internal assessments to training, documentation, audits, and the final application, following a clear path ensures success.

The costs involved, such as around $2,050 for training and $450 for administrative fees, are investments that can lead to noticeable improvements in quality and efficiency. Print professionals should also account for potential equipment updates, including hand-held measurement tools, color transformation software, and lighting that complies with ISO 3664 standards.

As highlighted earlier, Fogra certification brings tangible benefits: better print quality, streamlined operations, and cost reductions. It also strengthens a business’s competitive edge by showcasing its commitment to high standards and expertise in print processes. This certification not only reassures customers of service reliability but also fosters a culture of excellence that benefits both teams and clients alike.

Take Miro Printing & Graphics Inc. in Hackensack, NJ, as an example. This full-service print shop has used Fogra certification to reinforce its dedication to quality, ensuring consistent performance across various printing disciplines.

With a validity of two years, the certification encourages businesses to stay aligned with evolving industry standards and fosters continuous improvement. While the process may be demanding, the rewards – enhanced quality, operational efficiency, and customer satisfaction – are well worth the effort.

Ultimately, maintaining Fogra certification requires a steadfast commitment to excellence. Those who embrace this challenge gain not only the recognition of a respected institution but also the ability to guide their customers effectively across both digital and offset workflows.

FAQs

What are the key benefits of Fogra certification for small print shops?

Fogra certification provides a range of benefits for small print shops aiming to boost their credibility and improve how they operate. Earning this certification signals a dedication to top-tier printing standards and confirms that your processes align with globally recognized benchmarks. This not only strengthens client confidence but also distinguishes your business in a crowded market.

On top of that, Fogra certification can streamline your workflows by ensuring your equipment and procedures are fine-tuned for consistent, high-quality results. It can also open up new opportunities, as many clients and industries prefer working with certified providers who can deliver dependable and professional services.

What steps should print professionals take to prepare for the Fogra certification audit and exam?

To prepare for the Fogra certification audit and exam, it’s crucial to start by familiarizing yourself with Fogra’s detailed requirements and standards. Make sure your equipment is calibrated correctly and that your processes are running consistently before you even submit your application.

Take the time to fully understand the certification criteria and collect any required documentation or evidence of compliance. Running internal audits or trial tests can be a smart way to pinpoint and fix any potential problems ahead of time. A thorough preparation approach not only boosts your confidence but also improves your chances of a successful audit and exam outcome.

How can print professionals maintain their Fogra certification and stay compliant during the two-year certification period?

To keep your Fogra certification intact over the two-year period, there are a few important steps you should follow. Start by ensuring your printing processes consistently align with Fogra standards. This means scheduling regular quality checks and staying informed about any changes to the certification requirements. Calibrating your equipment regularly and following strict color management protocols are also critical for ongoing compliance.

It’s also a good idea to maintain detailed records of your production processes, including any adjustments you make over time. These records can be incredibly useful during audits or reviews. If you ever feel uncertain about meeting compliance standards, reaching out to a professional service like Miro Printing & Graphics Inc. could be a smart move. They specialize in advanced printing techniques and quality control, offering the expertise needed to support your business.

Related Blog Posts

- Soft Proofing Techniques for Accurate Colors

- ISO 2846: Ink Color Standards Explained

- Proofing Standards in Printing: Key ISO Guidelines

- Fogra Standards for Consistent Print Results

https://app.seobotai.com/banner/banner.js?id=68f037611019c13c0b247de7