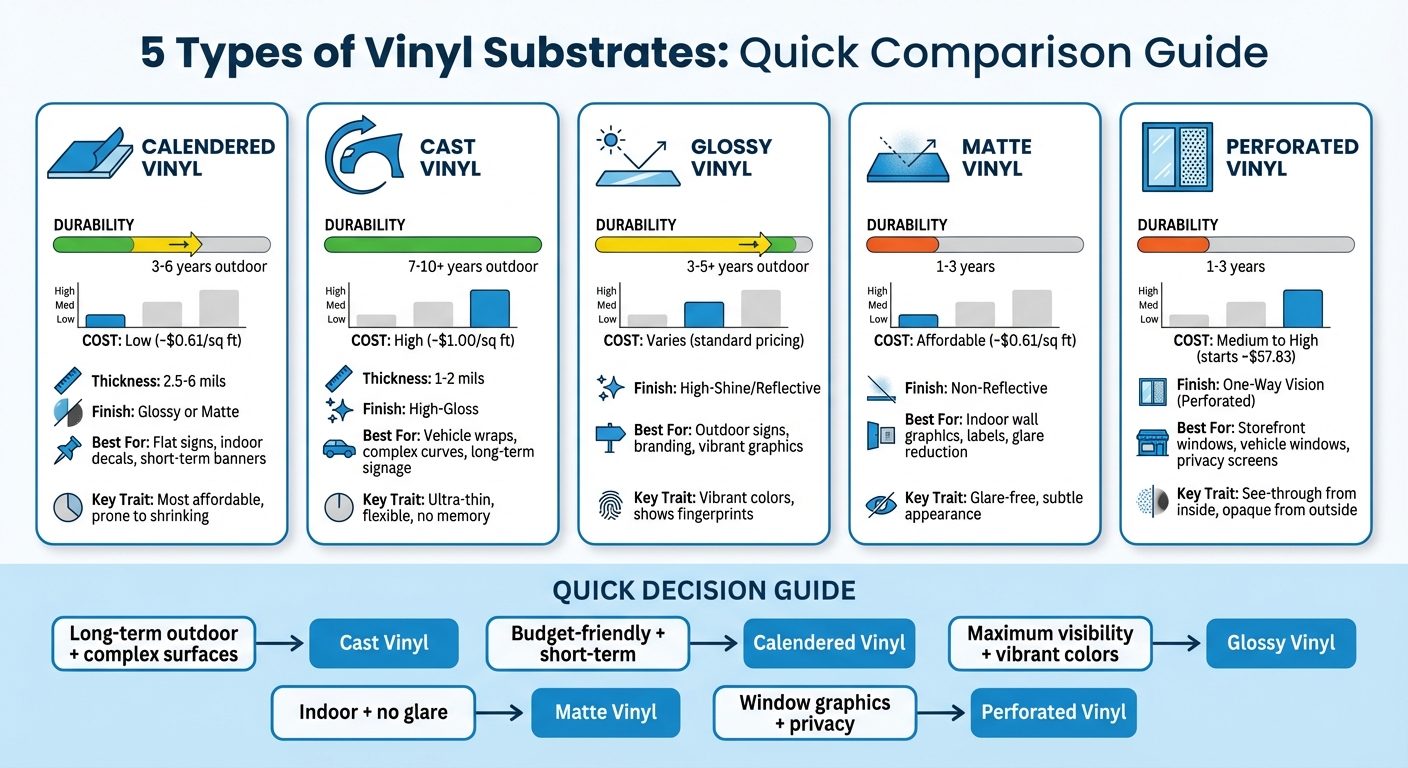

Vinyl substrates are a go-to material for printing projects due to their durability, flexibility, and ability to adhere to various surfaces. Choosing the right type of vinyl can make or break your project, whether it’s for short-term signage or long-term vehicle wraps. Here’s what you need to know:

- Calendered Vinyl: Affordable and great for flat surfaces or short-term use, but less durable and prone to shrinking over time.

- Cast Vinyl: Thin, flexible, and long-lasting, ideal for complex surfaces like vehicle curves, but comes at a higher cost.

- Glossy Vinyl: Reflective and vibrant, perfect for attention-grabbing designs, though it may show fingerprints or glare.

- Matte Vinyl: Non-reflective and glare-free, best for indoor use or subtle visuals.

- Perforated Vinyl: Designed for windows, offering one-way visibility while maintaining vibrant graphics.

Quick Tip: For long-term outdoor projects or intricate surfaces, invest in cast vinyl. For budget-friendly, short-term needs, calendered vinyl is a solid choice.

Quick Comparison

| Vinyl Type | Durability (Outdoor) | Cost | Finish Type | Best Use Cases |

|---|---|---|---|---|

| Calendered | 3–6 years | Low (~$0.61/sq ft) | Glossy or Matte | Flat signs, indoor decals, short-term banners |

| Cast | 7–10+ years | High (~$1.00/sq ft) | High-Gloss | Vehicle wraps, complex curves, long-term signage |

| Glossy | 3–5+ years | Varies | High-Shine | Outdoor signs, branding, vibrant graphics |

| Matte | 1–3 years | Affordable | Non-Reflective | Indoor wall graphics, labels, glare reduction |

| Perforated | 1–3 years | Medium to High | One-Way Vision (Perforated) | Storefront windows, vehicle window graphics |

The right vinyl depends on your project’s surface, budget, and lifespan requirements. Read on for a detailed breakdown of each type.

Vinyl Substrate Types Comparison: Durability, Cost, and Best Uses

Roland BN20/20A Media Guide | What Material Do I Use?

sbb-itb-ce53437

1. Calendered Vinyl

Calendered vinyl is made by pressing molten PVC through heavy rollers, which results in a thicker and more rigid film, typically ranging from 2.5 to 6 mils in thickness. For comparison, cast vinyl is usually around 2 mils thick. This manufacturing process also means the material tends to shrink when exposed to heat.

Cost

When it comes to affordability, calendered vinyl stands out as the budget-friendly choice. It can cost up to four times less than cast vinyl. Within this category, monomeric films are the most affordable and are perfect for entry-level needs, while polymeric films provide better durability and performance.

"If cast vinyl is king, then calendared vinyl is the prince of vinyl… Less expensive than cast vinyl, it is ideal for interior signage as well as short term outdoor banners and signs."

Durability

The outdoor lifespan of calendered vinyl varies depending on the type. Monomeric films typically last 2–4 years, while polymeric films can endure for 5–8 years. However, the material’s tendency to shrink over time can affect its long-term reliability.

"Calendared film tends to shrink over time, resulting in less resistance to the elements. However, it is more economically efficient, making it perfect for shorter term signs and banners."

- Alexandra LaPorta, Grimco

These durability traits make calendered vinyl a solid option for short- to medium-term projects.

Ideal Applications

Calendered vinyl works best on flat surfaces or areas with gentle curves. It’s a great fit for point-of-purchase displays, indoor wall graphics, floor murals, and temporary promotional signage. It’s also suitable for partial vehicle graphics on flat-sided vehicles like box trailers or pickup trucks.

However, it’s not recommended for complex surfaces like deep recesses, corrugated areas, or intricate curves. In these situations, the material’s memory can cause issues like lifting or adhesive lines. Always pair calendered vinyl with a compatible laminate, and avoid using cast laminates unless specifically advised by the manufacturer.

2. Cast Vinyl

Cast vinyl is created by pouring a liquid mixture onto a casting sheet and then baking it to evaporate the solvents. This process leaves behind a relaxed, ultra-thin film (just 1–2 mils thick) with no memory, unlike calendered vinyl. The result is a highly flexible material with a smooth, professional finish.

Durability

When it comes to longevity, cast vinyl stands out. It offers outdoor durability ratings ranging from 7 to 10 years, with some premium options lasting up to 12 years. The casting process gives it excellent dimensional stability, helping it resist fading, cracking, and UV damage far better than lower-grade alternatives.

"Cast vinyls are more durable than calendered vinyl, with many cast products rated at seven or more years of outdoor durability."

This durability makes it a go-to choice for challenging applications on intricate surfaces.

Ideal Applications

The thin and flexible nature of cast vinyl makes it perfect for complex surfaces. It conforms easily to curves, rivets, and deep recesses without lifting or bubbling. This makes it an excellent choice for full vehicle wraps, fleet graphics, marine applications, and architectural graphics on textured surfaces. It’s also ideal for high-end outdoor signage and premium branding projects where a flawless finish is essential.

Popular products in this category include 3M 1080, Avery SW900, and Briteline WrapCAST. To maximize performance, always pair cast vinyl with a cast over-laminate. Mixing it with a calendered laminate is not recommended and may even void warranties.

Cost

While cast vinyl delivers exceptional performance, it comes at a higher price. It typically costs two to three times more than calendered vinyl. However, for long-term projects, the higher upfront cost often pays off. Cast vinyl lasts longer, retains its appearance, and is easier to remove after years of use. It’s best suited for projects expected to last 7 years or more or for applications requiring superior conformability, which justifies the premium price.

3. Glossy Vinyl

Glossy vinyl stands out with its smooth, reflective surface that delivers vibrant colors and a high-shine finish. This eye-catching material is perfect for promotional materials, retail displays, and vehicle wraps, where grabbing attention is the goal.

"Glossy vinyl is a high-performance, custom-shaped sticker that you can apply to almost anything, from a storefront window to the side of a company van."

- Emma Davis, Content Writer, 4over4

Finish Type

The glossy finish amplifies light reflection, creating a polished, vibrant appearance. Its specialized substrates are designed with an exceptional white point and high ink capacity, ensuring accurate color reproduction and photorealistic prints. While this finish is perfect for bold, attention-grabbing graphics, it does have some drawbacks. Its reflective surface can highlight fingerprints and may cause glare in bright lighting.

Durability

Glossy vinyl comes in two main types: cast and calendered, each offering a different lifespan. Cast glossy vinyl is built to last, with an outdoor durability of 8 to 10 years . On the other hand, calendered glossy vinyl is more budget-friendly but typically lasts between 2 and 6 years outdoors. To extend the life of glossy vinyl, adding a clear laminate or coating is recommended. This extra layer protects against UV rays, scratches, and weather damage.

Ideal Applications

Glossy vinyl shines in commercial uses like vehicle wraps and fleet graphics, where visibility is key. It’s also a great choice for storefront window decals, product labels, and backlit displays. For personal projects, glossy vinyl works well for custom laptop stickers, water bottles, and heat transfer vinyl (HTV) designs for apparel. HTV applications can usually endure 30 to 50 wash cycles, making them practical for everyday use.

Cost

The cost of glossy vinyl varies depending on its type. Cast glossy vinyl, known for its superior durability and flexibility, costs around $1.00 per square foot. Meanwhile, ultra-calendered options are more affordable, priced at about $0.61 per square foot, with entry-level rolls starting at approximately $7.90 . The higher price of cast vinyl reflects its advanced manufacturing process, making it ideal for long-term, high-visibility projects .

Up next, we’ll dive into matte vinyl, which offers a more subdued, non-reflective finish.

4. Matte Vinyl

Matte vinyl stands out with its non-reflective finish, designed to reduce glare in bright settings. Unlike its glossy counterpart, matte vinyl ensures graphics stay crisp and easy to view from various angles, even under direct lighting.

"Selection should be based on visual esthetics and lighting conditions to ensure a balance of ‘optimal viewing’ of the displayed image."

- AGL Inc.

Finish Type

The matte finish not only minimizes glare but also elevates the overall presentation of graphics. It delivers a polished, uniform look by deepening colors and ensuring consistency across the design. Matte white vinyl, in particular, is engineered for excellent color accuracy and can be paired with high-gloss or matte overlaminates to provide added protection from UV rays and abrasion .

Durability

When it comes to durability, standard matte vinyl typically lasts about four years in vertical applications. Premium-grade versions, however, can endure six to eight years, even in varying conditions . Most matte vinyl options use a 3-mil film with a 1-mil adhesive and feature micro-channel air egress technology, which helps eliminate bubbles during installation.

Ideal Applications

Matte vinyl is a versatile choice for both indoor and outdoor signage, especially in areas with strong overhead lighting. Its non-glare surface makes it a great option for wall graphics, murals, trade show displays, retail point-of-purchase stands, storefront windows, and custom decals. With options for permanent, removable, or repositionable adhesives, it can accommodate everything from long-term installations to temporary marketing campaigns.

Cost

One of the most appealing aspects of matte vinyl is its affordability. Ultra-calendered matte vinyl averages about $0.61 per square foot, while premium cast matte vinyl is priced around $1.00 per square foot. This cost-effective solution is ideal for projects where durability beyond five years isn’t a priority .

Next, explore perforated vinyl to see how it excels in window applications.

5. Perforated Vinyl

Perforated vinyl takes the matte vinyl concept a step further by offering a clever solution specifically for windows. Its standout feature? A unique one-way view effect. From the outside, the printed design looks solid and opaque, while from the inside, it acts like a tinted window – allowing natural light to filter through and providing a clear view outside .

"Perforated vinyl allows you to see an opaque design from outside the building, but see right through it from the inside."

Finish Type

This material is designed with a white print surface to deliver vibrant, eye-catching colors and a black adhesive backing to enhance the one-way vision effect. Standard perforated vinyl measures 0.016 inches thick – about the same as four sheets of paper – and is made from calendered adhesive vinyl. It comes in various punch patterns, such as the common 50/50 pattern, which removes half the surface area, and the 80/20 pattern, which offers more print area for sharper graphics and better readability .

Durability

When installed and cared for properly, perforated vinyl can last 3 to 5 years. It’s built to handle tough conditions like rain and UV rays, making it both weatherproof and waterproof. For vehicles, laminating the vinyl is highly recommended to prevent dirt and water from clogging the tiny holes, which could reduce visibility from the inside .

Ideal Applications

Perforated vinyl shines in scenarios where maintaining visibility from one side is crucial. It’s a go-to choice for storefront graphics, turning windows into advertising space without sacrificing interior light. It’s also popular for vehicle windows, offering mobile branding opportunities, and as privacy screens for glass-walled conference rooms. For vehicle windows, a 50/50 punch pattern balances visibility and design, while a 60/40 pattern works better for storefronts, providing a smoother, more polished graphic. Inside-mount options, with adhesive on the printed side, add an extra layer of protection against vandalism in busy areas .

Cost

Custom perforated window vinyl begins at about $57.83, placing it in the mid-range price category. Though it shares a calendered base with more affordable monomeric vinyl, its specialized micro-perforation process and one-way vision capability make it a more tailored and advanced option.

Comparison Table

Here’s a quick summary of the key features of different vinyl types. This table compares their durability, cost, finish, and best use cases, making it easier to decide which one fits your needs.

| Vinyl Type | Durability (Outdoor) | Typical Cost | Finish Type | Best Use Cases |

|---|---|---|---|---|

| Calendered Vinyl | 3–6 Years | Low to Medium (~$0.61/sq ft) | Glossy or Matte | Flat signs, banners, indoor decals, short-term projects |

| Cast Vinyl | 7–10+ Years | High (~$1.00/sq ft) | High-Gloss | Vehicle wraps, complex curves, long-term outdoor signage |

| Glossy Vinyl | 3–5+ Years (varies by base) | Standard | High-Shine | Outdoor signs, branding, vibrant graphics |

| Matte Vinyl | 1–3 Years (varies by base) | Standard | Non-Reflective | Indoor wall graphics, labels, glare reduction |

| Perforated Vinyl | 1–3 Years | Medium to High | One-Way Vision (Perforated) | Storefront windows, vehicle window graphics, privacy screens |

Cast vinyl stands out for its durability and ability to handle complex surfaces like curves and rivets. It lasts 7–10+ years outdoors but comes at a higher cost of about $1.00 per square foot. On the other hand, calendered vinyl, priced at approximately $0.61 per square foot, offers a more budget-friendly option with a shorter lifespan of 3–6 years. Perforated vinyl, known for its one-way vision design, is moderately priced and works well for privacy screens or window graphics, though it has a shorter outdoor lifespan.

"Cast vinyl is recommended for complex surfaces with curves, rivets, and corrugations. These films typically last 7+ years outdoors."

- Alexandra LaPorta, Grimco

When choosing between glossy and matte finishes, consider the environment and desired look. Glossy finishes create vibrant, eye-catching designs, while matte finishes reduce glare, making them ideal for indoor spaces or subtle visuals. For outdoor projects requiring durability and flexibility, cast vinyl is worth the investment. Meanwhile, calendered vinyl is a practical choice for short-term or indoor applications where cost is a priority.

This breakdown should help you pick the right vinyl for your project.

Conclusion

Choosing the right vinyl substrate starts with understanding your project’s specific requirements. For flat, short-term applications, calendered vinyl is a cost-effective option at around $0.61 per square foot. On the other hand, cast vinyl, priced at approximately $1.00 per square foot, offers superior durability and flexibility, making it ideal for projects involving complex curves. If you’re aiming for vibrant outdoor graphics, a glossy finish enhances color saturation, while matte vinyl works best indoors by reducing glare. For unique applications like storefronts or vehicle windows, perforated vinyl provides one-way visibility, balancing functionality and aesthetics.

It’s also essential to consider surface complexity and environmental factors when selecting vinyl. For instance, while calendered vinyl is affordable and effective for indoor or temporary outdoor use, it can shrink under heat due to its "memory", with a lifespan of 2 to 6 years. Meanwhile, cast vinyl is better equipped to handle long-term exposure and challenging surfaces.

The finish plays a crucial role in the final appearance and usability of your project. Glossy finishes amplify colors for striking visuals, while matte finishes ensure clear, glare-free indoor displays.

To see these options in action, companies like Miro Printing & Graphics Inc. in Hackensack, NJ, specialize in tailoring vinyl solutions to local business needs. Their expertise ensures that the chosen materials align with environmental conditions and aesthetic goals, delivering high-quality results without overspending.

Whether you’re working on vehicle wraps, window displays, or indoor wall art, selecting the right vinyl type ensures your project not only looks professional but also holds up for as long as you need.

FAQs

What’s the difference between cast and calendered vinyl?

Cast and calendered vinyl are distinct in their manufacturing processes, which directly influence their flexibility, durability, and best-suited applications.

Cast vinyl is made by pouring liquid PVC onto a casting sheet, forming a thin film around 1–2 mils thick. This process results in a highly flexible material that easily conforms to complex shapes like curves, rivets, and corrugations. It’s built to last, with outdoor durability exceeding 7 years, and it resists both fading and shrinkage. However, this premium quality comes with a higher price tag.

Calendered vinyl, in contrast, is produced by rolling solid PVC into thicker sheets, typically 2.5–4 mils thick. While it’s less flexible, it works well for flat or simple surfaces like indoor signs or temporary banners. It’s a more budget-friendly option but offers a shorter lifespan, generally lasting 3–6 years outdoors. Over time, exposure to heat can cause it to shrink.

To put it simply: opt for cast vinyl when working on intricate or long-term projects, and go with calendered vinyl for cost-effective, short-term needs on flat surfaces.

How can I choose the best vinyl finish for my printing project?

Choosing the right vinyl finish comes down to a few key factors: the surface you’re working with, the environment, and how long you need the project to last. Start by evaluating the surface. Smooth surfaces like glass or metal are great for removable vinyl, while rough or outdoor surfaces often need permanent vinyl to ensure it sticks properly.

For outdoor projects or anything exposed to sunlight and weather, cast vinyl is a solid choice – it’s durable and resistant to UV rays. On the other hand, calendared vinyl is a more budget-friendly option that works well for short-term indoor projects.

Think about the finish you want, too. A gloss finish makes colors pop, matte minimizes glare, and satin gives you a middle-ground look. If your project involves curved surfaces, cast vinyl is the way to go because of its flexibility. For flat surfaces, calendared vinyl does the job just fine.

Need help deciding? The experts at Miro Printing & Graphics Inc. can guide you to the perfect vinyl finish for your project. Their professional advice ensures you’ll get the best results for your specific needs.

What makes perforated vinyl a great choice for window graphics?

Perforated vinyl is a clever material with tiny holes that let light pass through, creating a unique effect. It’s perfect for window graphics because it allows people outside to see the printed design clearly, while those inside can still enjoy natural light and an open view. This makes it a smart and stylish choice for storefronts, office spaces, and even vehicle windows.

Related Blog Posts

- Substrate Selection for Digital Printing

- Top 5 Substrates for Multi-Climate Printing

- Large Format Paper Types Explained

- Guide to Substrate Lifespan in Large Format Printing

https://app.seobotai.com/banner/banner.js?id=6969a7b60a871bef4ad1a448