ISO 17972 is a standard that ensures accurate color communication in the printing industry. While its adoption offers benefits like improved color consistency and reduced errors, many businesses encounter challenges, such as:

- Workflow Issues: Miscommunication between brands and printers often leads to errors and inefficiencies.

- Technology Gaps: Legacy systems and software incompatibility with ISO 17972 can hinder implementation.

- Training Needs: Teams often lack the knowledge to interpret spectral data and use the standard effectively.

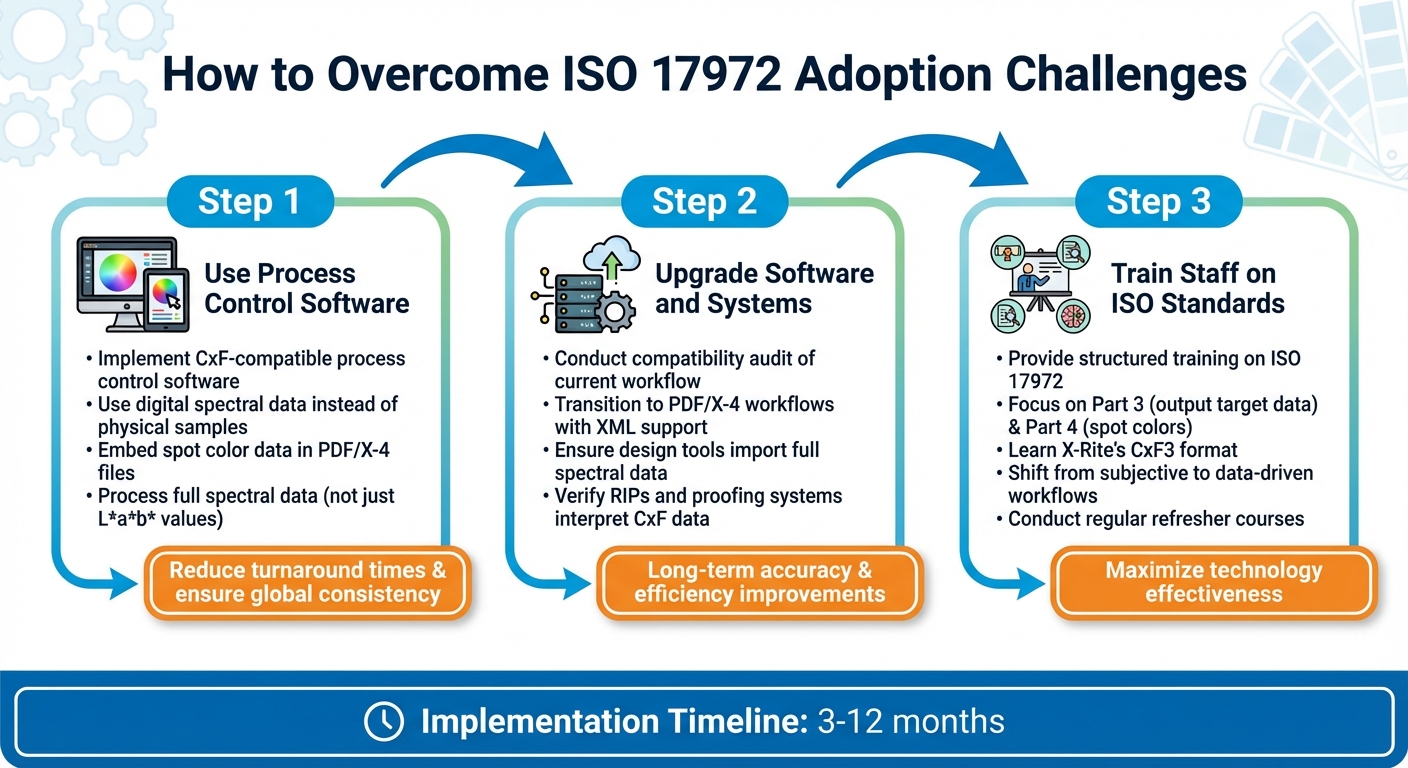

To overcome these obstacles, businesses should upgrade to compatible systems, invest in process control software, and provide structured training for their teams. Though implementation may take 3–12 months, the long-term gains include better color precision, fewer reprints, and stronger client relationships.

Beyond ISO 12647: New ISO standards for the printing industry Webinar

Common Challenges in Adopting ISO 17972

ISO 17972 aims to improve color communication, but adopting it isn’t always straightforward. Print businesses often face technical and organizational obstacles that can slow down implementation. Understanding these challenges is key to navigating them effectively. Below, we break down the main hurdles and offer practical insights.

Inconsistent Workflow Communication

A major issue lies in fragmented communication between printers and brands. The use of varied tools and file formats often leads to manual data entry, increasing the likelihood of errors. On top of that, print requirements are frequently described in vague terms like "superior quality", which leaves room for inconsistent interpretations among stakeholders. This lack of clarity can result in costly physical proofs and production delays. Cindy Cooperman, VP of Brand Global Strategic Accounts at X-Rite, highlights the burden of this process:

"The sample and proofing process is burdensome and cost prohibitive, as the requirements continue to expand. Costs can quickly add up when considering the expense to produce, ship, evaluate, and store hundreds and thousands of print proofs and samples."

To tackle these issues, standards like the Print Requirements Exchange (PRX, ISO 20616-1) and Print Quality Exchange (PQX, ISO 20616-2) have been introduced. These frameworks help standardize how print requirements flow from buyers to printers and how quality attributes are reported back for review.

Software and Hardware Compatibility Problems

Technical limitations also pose a challenge. Many legacy systems and proprietary formats lack native XML support, which is essential for ISO 17972. Additionally, the wide range of color management tools available – each with its own methods for data handling – complicates integration. Some measurement tools and software currently in use don’t even support ISO 17972.

Specific parts of the standard, like ISO 17972-4:2018 for spot color characterization, have their own constraints. For instance, it applies only to isotropic (paper-like) substrates and requires precise ink and paper combinations from the characterization process, limiting its use in complex packaging environments. While vendors like Chromachecker, MeasureColor, Techkon, and X-Rite provide solutions aligned with these standards, upgrading existing systems often demands significant investment and careful planning.

Training and Knowledge Gaps

One of the most underestimated challenges is the human factor. ISO 17972 defines file formats but doesn’t specify the processes or methodologies needed to interpret the data. This lack of direction can confuse teams transitioning from manual workflows to more objective, data-driven ones. Eddy Hagen, an independent consultant and author at Insights4print.ceo, emphasizes the importance of clear communication:

"If you want your print jobs to be executed perfectly to your wishes, you need to communicate those wishes clearly and unambiguously. Communicating your brand colors is best done scientifically: as Lab-values or even spectral values."

Without adequate training and guidance, teams often struggle to replace subjective press checks with objective workflows based on spectral and XML data. These knowledge gaps can slow down adoption and lead to mistakes that compromise the benefits of standardization. Bridging these gaps is crucial for achieving the consistent results promised by ISO 17972.

How to Overcome ISO 17972 Adoption Challenges

3-Step Guide to Overcoming ISO 17972 Adoption Challenges

Adopting ISO 17972 can feel overwhelming, but the right strategies – upgrading technology, refining workflows, and ensuring proper training – can bridge the gaps in communication, compatibility, and skills.

Use Process Control Software

Process control software that supports the Color Exchange Format (CxF) is a game-changer for streamlining workflows and cutting reliance on physical samples. By using digital spectral data, you ensure consistency and enable global sharing, which can significantly reduce turnaround times.

Software aligned with ISO 17972-4 (CxF/X-4) allows you to embed spot color data directly into PDF/X-4 files. This creates a secure "job bag" that retains all essential color information during file transmission. As Ray Cheydleur, Printing and Imaging Product Portfolio Manager at X-Rite, explains:

"X-Rite’s CxF3, and now ISO CxF, ensures an accurate and efficient exchange of digital standards, measurements and metadata."

Advanced tools like the ORIS CxF Toolbox and CxF CLOUD can even predict ink behavior during overprinting or sequence changes. When choosing software, make sure it processes full spectral data instead of just L*a*b* values to maximize accuracy.

Upgrade Software and Systems

Older systems often fall short when it comes to supporting ISO 17972. Many legacy tools lack native XML support, making it crucial to transition to PDF/X-4 workflows. Unlike earlier PDF versions, PDF/X-4 fully supports the spot color and overprint features defined by the standard.

Start by conducting a thorough compatibility audit of your workflow. Ensure that your design tools can import full spectral data – many older applications are limited to handling L*a*b* values. Similarly, confirm that your RIPs and proofing systems can accurately interpret and reproduce embedded CxF data. This includes ensuring proper communication of device settings, filter adjustments, and substrate details.

While upgrading systems does require upfront investment, the improvements in accuracy and efficiency often justify the cost in the long run.

Train Staff on ISO Standards

Even the best technology won’t deliver results if your team doesn’t know how to use it effectively. ISO 17972 defines file formats but doesn’t specify how to interpret the data, making structured training essential. Laurel Brunner, Managing Director of Digital Dots Limited, emphasizes this point:

"With the adoption of ISO 17972-1:2015, a new dimension has now been added to standards compliance that will help everyone in the color workflow more easily produce color quality within expected tolerances."

Tailor training programs to your specific workflow needs. For example, focus on Part 3 for output target data and Part 4 for spot colors. Staff should also develop a strong understanding of X-Rite’s Color Exchange Format version 3 (CxF3), which serves as the backbone of ISO 17972. This knowledge helps shift workflows from subjective, manual methods to objective, data-driven processes based on spectral and XML data.

Consider collaborating with industry organizations or vendors that offer certification programs in color management and ISO standards. Hands-on training that covers practical scenarios – like interpreting spectral data, setting up measurement conditions, and resolving compatibility issues – can be especially effective. Pairing training with workflow audits ensures that both technical and operational improvements are reinforced. Regular refresher courses can also keep your team’s skills sharp as technologies and standards evolve.

At Miro Printing & Graphics Inc., ongoing training and workflow audits play a critical role in maintaining quality and consistency for every project.

sbb-itb-ce53437

Benefits of Adopting ISO 17972

Adopting ISO 17972 can bring meaningful improvements to print businesses. While implementing the standard may pose initial challenges, it ultimately reshapes how companies manage color, collaborate with stakeholders, and stand out in a competitive industry. These advancements directly affect both operational efficiency and client satisfaction.

Improved Color Accuracy and Consistency

ISO 17972 takes color precision to the next level by using spectral measurement data rather than relying solely on Lab or CMYK values. This approach captures the entire visible spectrum of a color, providing a more comprehensive profile. Unlike physical swatches that can fade or get damaged, digital spectral definitions remain intact and are embedded directly into PDF/X-4 or PDF/X-6 files, ensuring long-term reliability.

This level of accuracy has a noticeable impact on production. Traditional CMYK can only match about 55% of PANTONE Spot colors, while digital CMYK raises that to 65%. By incorporating Extended Gamut Printing (ECG) – which adds orange, green, and violet to the CMYK palette – businesses can achieve up to 90% accuracy in matching PANTONE Spot colors. This reduces waste, reprints, and rejected jobs. Dan Gillespie, Director of Technical Services at Alder Technology, highlights the importance of spectral definitions:

"We need the spectral definitions – we can’t continue to use named colors with variable target values and we can’t accurately print spot color tints and overprints without them."

Enhanced Communication Between Stakeholders

ISO 17972 creates a standardized framework for color communication, ensuring that brand owners, designers, and print providers are all on the same page. Ray Cheydleur, Printing and Imaging Product Portfolio Manager at X-Rite Pantone, explains its significance:

"ISO CxF/X (ISO 17972-1:2015) with additional parts provides a framework for exchanging everything from target data to spot color tone values. It ensures an accurate and efficient exchange of digital standards, measurements, and metadata."

This universal approach eliminates confusion in the production process. All relevant color data – such as spot colors, tolerances, substrate specifications, and measurement conditions – is securely included in the digital job file. With everyone working from the same data, disputes over color matching are minimized, and production timelines improve. INX Subject Matter Experts emphasize this benefit:

"The ability to achieve color faster means less waste, fewer minutes (or hours) spent adjusting color, more productive time for presses, the ability to do color-consistent reorders."

This clarity not only boosts efficiency but also strengthens your competitive edge.

Competitive Market Advantage

Once businesses overcome the initial hurdles of adopting ISO 17972 – such as compatibility, training, and communication – they are well-positioned to thrive in the market. Certification signals a commitment to quality and reliability, which resonates with clients. In a printing industry projected to be worth $494.53 billion in 2023, adhering to internationally recognized standards can set a business apart.

Clients often prefer working with providers who meet global standards, as it reflects a dedication to excellence and best practices. ISO compliance also simplifies the process of competing for international contracts and building cross-border partnerships. Furthermore, the use of standardized color data ensures consistent reorders, which is essential for maintaining strong, long-term client relationships.

For print service providers like Miro Printing & Graphics Inc., adopting ISO 17972 can enhance production precision, streamline operations, and solidify their reputation in the competitive U.S. market.

Conclusion

Implementing ISO 17972 can be a challenging endeavor for print businesses, often involving hurdles like workflow communication gaps, software compatibility issues, and the need for staff training. However, with focused investments in technology, employee development, and process refinement, these challenges can be effectively addressed.

The process typically takes between 3 to 12 months to complete. To start, conduct a gap analysis to identify areas needing attention, then phase the implementation to prioritize critical aspects. This phased strategy not only helps manage financial constraints but also eases the learning curve for employees. As Fujifilm highlights:

"Achieving ISO certification can improve internal processes, enhance market competitiveness and build customer trust".

Strong leadership plays a pivotal role in ensuring a smooth transition. Top management must dedicate adequate resources and promote a culture of ongoing improvement. Designating an internal ISO champion to oversee the project ensures someone maintains a comprehensive perspective throughout the process. Additionally, involving employees early on is crucial – when staff understand how standardized workflows will simplify their roles, resistance to change often diminishes.

The rewards are considerable. Businesses can expect enhanced color accuracy, reduced waste, and stronger client relationships. For example, companies like Miro Printing & Graphics Inc. have seen significant improvements in operational efficiency and market positioning by adopting ISO 17972. Maintaining certification requires regular internal audits and management reviews over a three-year period. With proper preparation and dedication, the long-term advantages far outweigh the initial investment, setting the stage for sustained success.

FAQs

How can businesses enhance communication in their printing workflows?

To enhance communication within printing workflows, businesses can consolidate project details into a single, cloud-based platform accessible to all team members in real time. This approach keeps designers, production staff, sales teams, and clients on the same page, whether they’re working remotely or following flexible schedules. A strong management system that incorporates tools for file sharing, collaboration, and job tracking can significantly reduce errors, streamline proof approvals, and eliminate the back-and-forth of lengthy email threads.

Equally important is integrating software systems to ensure information flows smoothly. Linking tools like digital proofing platforms and automation modules allows production data, client feedback, and cost information to be shared automatically, minimizing manual tasks. Consistent file naming practices, regular cross-department check-ins, and aligning workflows with ISO 17972 standards can further cut down on miscommunication and help projects stay on schedule.

What steps can businesses take to make their legacy systems compatible with ISO 17972?

To bring legacy systems in line with ISO 17972 standards, start by thoroughly assessing your current hardware, software, and workflows. Compare them against the standard’s requirements, paying close attention to areas like color measurement, data exchange formats, and printing conditions. This evaluation will help pinpoint gaps that need addressing. Potential upgrades might involve incorporating ICC profile support, updating color measurement tools, or implementing middleware to ensure compatibility.

After making the necessary updates, integrate these new processes into your daily operations. Create clear workflows for essential tasks such as RGB-to-CMYK conversions, proof verification, and quality control checks. Ensure your team is well-trained on these updated procedures. To maintain compliance and deliver consistent, high-quality results, make regular equipment calibration and periodic audits a routine part of your operations. These steps will help your legacy systems meet ISO 17972 standards while continuing to provide the reliability your clients depend on.

Why is ISO 17972 training important for successful implementation?

Training on ISO 17972 plays a key role in helping employees grasp the technical requirements of the standard. This knowledge ensures the standard is applied correctly, minimizing errors and inconsistencies. Without proper training, businesses may encounter challenges like uneven processes, quality problems, or even resistance to new practices.

Providing thorough training helps organizations transition more smoothly, uphold high-quality print production standards, and establish more efficient workflows. The result? Improved operations and strengthened client trust through consistently dependable outcomes.

Related Blog Posts

- ISO 2846: Ink Color Standards Explained

- Proofing Standards in Printing: Key ISO Guidelines

- Ultimate Guide to Fogra Prepress Software Integration

- How ISO 12647 Ensures Print Quality

https://app.seobotai.com/banner/banner.js?id=696d77d30a871bef4ad391f3