Fogra standards ensure accurate color reproduction in printing by providing measurable benchmarks. They align with ISO standards (like ISO 12647) to eliminate guesswork and disputes, making proofs legally binding and color-accurate. These standards cover various printing methods, including offset, digital, and textile printing. Fogra-certified workflows help maintain consistency, from proofing to final prints, by using tools like ICC profiles, spectrophotometers, and standardized lighting. As of 2026, over 430 companies and 1,600 systems are Fogra-certified globally.

Key takeaways:

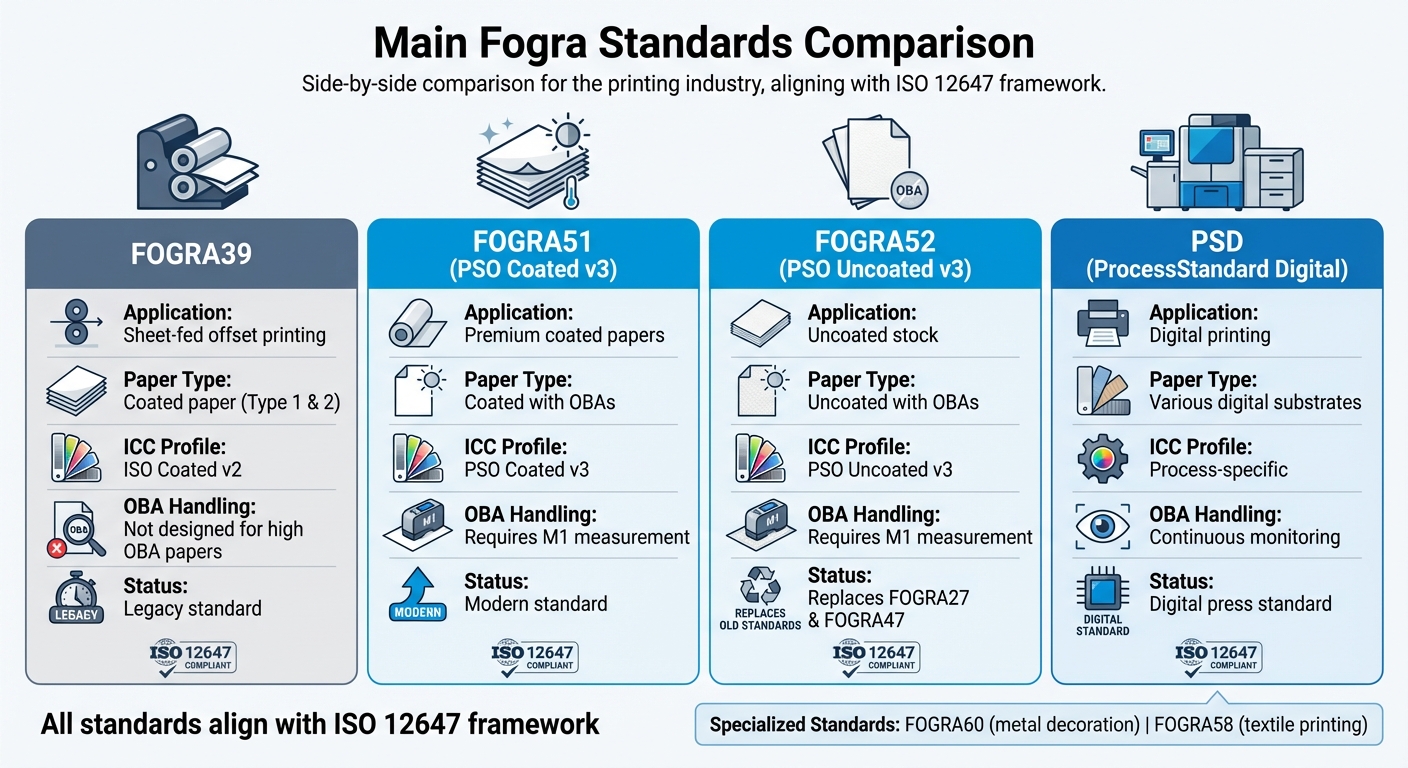

- Main standards: FOGRA39 (offset), FOGRA51/52 (OBA papers), PSD (digital printing).

- Tools: Fogra Media Wedge, ISO 3664 lighting, ICC profiles.

- Benefits: Precision, fewer disputes, and compliance with ISO 12647.

Fogra simplifies color communication, ensuring consistent results across all stages of printing.

de FOGRA 39 a FOGRA 51. APRENDE, CONVIERTE y MIGRA a la nueva ISO 12647 de IMPRESIÓN

How Fogra Standards Control Color Quality

Fogra Standards Comparison Chart: FOGRA39 vs FOGRA51 vs FOGRA52 vs PSD

Fogra standards bring precision to color matching by setting clear, measurable criteria. Instead of relying on subjective visual judgments, these standards establish target values and tolerances for every aspect of color reproduction, ensuring consistency across the board. They bridge the gap between device-dependent values (like CMYK percentages) and device-independent color measurements (such as CIELAB), creating a direct link between digital files and printed results.

This scientific approach takes the uncertainty out of the equation. When a print or proof is evaluated against Fogra standards, the data either meets the defined tolerances or it doesn’t – no room for debate. The characterization data precisely maps ink percentages to color values, leaving no guesswork.

Main Fogra Standards Explained

Different printing processes and paper types demand tailored standards. FOGRA39 has been the go-to standard for sheet-fed offset printing on coated paper (Paper Type 1 and 2), working hand-in-hand with the ISO Coated v2 ICC profile. However, with modern papers incorporating high levels of Optical Brightening Agents (OBAs), FOGRA39 has struggled to address the resulting visual inconsistencies.

Enter FOGRA51 (PSO Coated v3), designed specifically for premium coated papers with OBAs. This standard requires M1 measurement conditions to account for the brightening agents, ensuring accurate visual matches. Similarly, FOGRA52 (PSO Uncoated v3) addresses uncoated stock with OBAs, replacing older standards like FOGRA27 and FOGRA47.

For digital printing, the ProcessStandard Digital (PSD) was developed to guarantee consistent color accuracy and reliable performance over long runs – essential for maintaining quality on digital presses. Fogra has also expanded its reach with specialized standards like FOGRA60 for metal decoration and FOGRA58 for textile printing.

How Fogra Standards Connect to ISO 12647

Fogra standards align seamlessly with the globally recognized ISO 12647 framework, which sets universal benchmarks for print quality. While ISO 12647 provides the overarching guidelines, Fogra translates these into practical, real-world applications. Their characterization data and certification processes help printers achieve ISO compliance with measurable accuracy.

"The contract proofing standard (ISO 12647) has established itself worldwide as the tool for colour communication and has put an end to the diffuse situation with various manufacturer-specific processes and specifications."

– Dr. Andreas Kraushaar, Head of Prepress, Fogra

ISO 12647 is divided into eight parts, covering everything from offset lithography (Part 2) to digital proofing (Part 7) and validation prints (Part 8). For instance, when a printer uses FOGRA51 characterization data, they adhere to ISO 12647-2 standards for offset lithography. The Fogra data provides critical metrics like L_a_b* values for solids and overprints, Tone Value Increase (TVI) targets, and hue angle specifications, making ISO compliance both achievable and measurable.

Companies such as Miro Printing & Graphics Inc. rely on these standards to deliver consistent, color-accurate proofs and final prints, ensuring quality every step of the way.

What You Need for Accurate Proof-to-Print Matching

Getting proof-to-print matching right is all about maintaining precise color standards, like those outlined by Fogra. To achieve this, you need the right tools, controlled lighting, and reliable measurement instruments. The essentials include standardized lighting, accurate ICC profiles, and dependable measurement devices. These elements work together to remove the guesswork, ensuring that what you see on a proof matches the final printed result. Let’s dive into how standardized viewing, ICC profiles, and objective measurements keep color consistency on point.

Why Standardized Viewing Conditions Matter

Lighting can play tricks on your eyes. A proof might look one way under fluorescent office lights, another under natural daylight, and completely different under incandescent bulbs. These shifts can lead to costly mistakes and unhappy clients. That’s why ISO 3664:2009 specifies D50 (5000K) illumination for all color-critical evaluations in the graphic arts industry.

"Colours are actions of light… Misjudgements due to incorrect lighting almost immediately lead to complaints and thus to increased costs." – Fogra

Certified viewing cabinets go beyond simply providing the right color temperature. They are evaluated on factors like color rendition, metamerism (how colors change under different light sources), UV energy levels, and even how evenly the light spreads across the viewing area. For companies pursuing certification, Fogra charges $1,100 for non-members ($770 for members) to audit a single viewing cabinet. Each additional cabinet costs $410 for non-members ($287 for members).

To ensure that staff involved in color approvals can accurately assess colors, the Farnsworth-Munsell 100 Hue Test is used to evaluate their ability to distinguish subtle differences in hue.

Using ICC Profiles for Color Accuracy

ICC profiles are the link between your digital files and the final printed product. By simulating exact printing conditions – whether for offset, digital, or large-format printing – they ensure consistent color reproduction across different devices and materials. Without the right profile, you’re left guessing how colors will turn out.

To get started, download the appropriate Fogra characterization data (e.g., FOGRA51, FOGRA52, or PSD) and embed it into your PDF/X files. These profiles need to be used consistently throughout your prepress workflow. Make sure your software handles PDF color transformations correctly and that your RIP (Raster Image Processor) respects the embedded profiles. For soft proofing, monitors must meet ISO 12646 and ISO 14861 standards to ensure that what you see on screen aligns with the intended print output.

Objective measurements can then confirm the color accuracy achieved digitally, providing an extra layer of confidence.

Measurement Tools for Color Verification

Accurate color measurement is non-negotiable. Spectrophotometers are the go-to tools for this, measuring the actual color values of prints and comparing them to reference data. They detect even slight color shifts and ensure compliance with ISO standards. These devices follow ISO 13655 guidelines, which specify proper measurement conditions, including the backing material (white or black) and illumination modes (M0, M1, or M2).

The Fogra Media Wedge CMYK V3 is a key tool for verifying proof accuracy. This control bar includes carefully defined color patches that represent critical values and tonal ranges. When measured with a spectrophotometer, it provides objective proof that your output meets ISO 12647-7 tolerances.

| Tool/Technology | Relevant Standard | Purpose |

|---|---|---|

| Viewing Cabinets | ISO 3664:2009 | D50 lighting for color evaluation |

| Media Wedge CMYK V3 | ISO 12647-7 | Control bar for color verification |

| Spectrophotometer | ISO 13655 | Physical measurement of color values |

| Softproof Monitor | ISO 12646 / 14861 | Consistent on-screen color display |

| Proofing Substrates | ISO 12647-7 | Certified paper for print simulation |

In digital printing workflows that follow ProcessStandard Digital (PSD), continuous monitoring for color drift is essential. You can use handheld spectrophotometers or integrate inline measurement systems directly into your press for automated checks. Basic PSD certification costs $3,625 for non-members ($2,537.50 for members), while recertification fees are $2,800 for non-members ($1,960 for members).

sbb-itb-ce53437

How to Apply Fogra Standards in Your Printing Workflow

Applying Fogra standards involves a step-by-step approach that ensures consistent color accuracy from the initial file preparation to the final printed product. By setting up clear checkpoints at each stage where color variations can occur, you create a reliable and repeatable workflow that builds client confidence. Here’s a breakdown of the workflow to maintain color consistency throughout production.

Workflow Steps from Data to Final Print

Start with data preparation: Export your files as PDF/X-4, embedding the appropriate Fogra profile (such as FOGRA51, FOGRA52, or a relevant legacy profile). This ensures that color intent is preserved across all software and RIPs in your workflow.

For contract proofing under ISO 12647-7, include the Fogra Media Wedge CMYK V3 on every proof. This wedge is essential for verifying compliance with color tolerances. Make sure to use proofing substrates that meet ISO 12647-7 standards. When working with modern bright white papers (like those under FOGRA51/52), set your spectrophotometer to M1 measurement mode to account for optical brighteners and UV content.

If you’re creating design proofs that don’t require full contract-level accuracy, you can follow ISO 12647-8 (Validation Print). This approach offers slightly broader tolerances while still delivering consistent and predictable color results.

Throughout the production process, frequent calibration is crucial. Regularly calibrate proofing printers and monitors to maintain alignment with the standards. For digital printing environments using ProcessStandard Digital (PSD), rely on drift detection tools – either handheld or inline – to catch color shifts early and prevent issues before they escalate.

"Prerequisites for professional colour communication are perfect print data, colour-accurate proof prints and correct matching conditions." – Fogra

By following these steps, you can ensure that every printed piece meets the stringent color standards required for reliable proof-to-print matching. This structured workflow also prepares you to take full advantage of certified proofing systems.

Benefits of Certified Proofing Systems

Using FograCert Contract Proofing Systems simplifies compliance with ISO 12647-7. These systems include pre-approved hardware, software, inks, and papers, eliminating the need for you to individually test and validate each component.

For companies aiming for ProcessStandard Digital (PSD) certification, the framework offers clear guidelines and objective testing through PSD PrintCheck. As of early 2026, Fogra has certified around 430 companies, 1,600 systems, and 110 individuals.

"The Fogra PSD certification is more and more a requirement of our customers. Our employees have a clear work quality standard and we have a clear criterion towards our customers." – Ulrich Schätzl, CEO of Schätzl Druck & Medien GmbH & Co. KG

The PSD Colour Data service takes automation a step further by verifying color accuracy for each print job. Using inline or handheld measurement devices, this system checks the Fogra Media Wedge and provides quality feedback (rated A, B, or C) within 2 to 4 working days. This fully digital verification process reduces manual effort and labor costs while maintaining objective quality standards. At $120 per print combination for non-members (or $84 for members), it’s a cost-effective way to document consistent quality throughout your production runs.

Fixing Common Proof-to-Print Problems

What Causes Color Mismatches

Color mismatches often arise due to issues with substrates, measurement settings, or viewing conditions. For instance, using non-OBA paper when the standard calls for OBA-rich paper (like FOGRA52) can alter the white point, resulting in a warmer proof.

Measuring papers with optical brighteners in M0 mode instead of M1 can also cause noticeable color shifts, introducing blue or yellow hues. Similarly, viewing conditions that don’t meet ISO 3664 standards – such as inconsistent 5000K lighting or insufficient UV content – can disrupt accurate color comparisons.

Software can also play a role. Standard ICC conversions in tools like Photoshop may inadvertently add too much magenta when working with FOGRA52 profiles, while specialized device-link profiles handle these conversions more accurately. Additionally, uncalibrated monitors or printing presses make achieving a reliable color match nearly impossible.

"Complications and complaints are usually caused by print data that has not been prepared correctly." – Fogra

Addressing these problems requires aligning substrates, measurement settings, and viewing conditions, as outlined below.

How to Fix Color Matching Issues

To resolve these mismatches, start by ensuring your proofing substrate matches the required standard. For FOGRA51/52, use proofing papers with optical brighteners. Verify accuracy with the Fogra Media Wedge CMYK V3 and measure using a spectrodensitometer to meet ISO 12647-7 tolerances.

Check that the measurement backing complies with ISO 13655 standards, as an incorrect backing can distort readings. When proofing, use the Absolute Colorimetric rendering intent to accurately replicate the source’s white point on your proofing paper. Avoid Perceptual rendering, which prioritizes visually "pleasing" results over precision.

Ensure your viewing booth maintains consistent 5000K lighting by using a reliable color temperature indicator. If color discrepancies persist, consider using the Farnsworth-Munsell 100 Hue Test to evaluate the color discrimination abilities of personnel. These adjustments integrate smoothly into Fogra-based workflows, helping to achieve consistent and accurate results.

Conclusion

Fogra standards serve as the foundation for achieving consistent proof-to-print accuracy. By replacing manufacturer-specific methods with globally recognized benchmarks, these standards ensure that proofs align with legal requirements and ISO 12647-7 color-accuracy guidelines. This structured approach supports every stage of a high-quality printing workflow.

But it’s not just about accuracy. Adopting standards like ProcessStandard Digital (PSD) can lead to practical benefits, such as quicker setup times, less waste from plate remakes, and fewer disagreements between print providers and their clients. As Ron Ellis, a consultant and author, succinctly puts it:

"Standards aid efficiency and efficiency leads to profits".

These certifications reinforce trust across the industry in Fogra’s reliability.

Managing the entire workflow effectively is crucial. This involves using standardized viewing conditions that comply with ISO 3664 and verifying substrates with tools like the Fogra Media Wedge CMYK V3. Dr. Andreas Kraushaar, Head of Prepress at Fogra, highlights this importance:

"Prerequisites for professional colour communication are perfect print data, colour-accurate proof prints and correct matching conditions".

For print providers aiming to secure top-tier contracts with global brands, Fogra certification offers verifiable proof of quality. Automated tools, such as PSD Colour Data, further simplify the process by reducing manual tasks and delivering feedback within just 2-4 working days, making quality assurance both faster and more efficient.

FAQs

What are Fogra standards, and how do they ensure color accuracy in digital printing?

Fogra standards are globally recognized guidelines designed to ensure consistent and precise color reproduction in digital printing. Among these is the ProcessStandard Digital (PSD), which defines clear target values and tolerances for achieving color accuracy. Certifications like PSD PrintCheck and PSD Color Data play a key role in this process, utilizing tools such as the Fogra MediaWedge to objectively measure and verify color consistency across print jobs.

Following Fogra standards allows printers to maintain dependable proof-to-print matching, ensuring the final printed product mirrors the original design. This level of accuracy is particularly crucial for projects where color fidelity is non-negotiable, such as branding materials or premium-quality prints.

What are the key tools for ensuring color consistency based on Fogra standards?

Achieving reliable proof-to-print results with Fogra standards relies on using the right tools to standardize color and maintain precision. Key resources include Fogra characterization data tailored for inks and substrates, test forms to assess image quality, and measurement backings aligned with ISO 13655 standards. Fogra also offers soft-proof lighting guidelines to ensure on-screen proofs are evaluated under ideal viewing conditions.

For digital printing, the ProcessStandard Digital (PSD) handbook outlines a comprehensive workflow to maintain consistent color throughout the production process. Tools like the Fogra Media Wedge CMYK V3 and FOGRACert certification play a critical role in ensuring proofs meet strict tolerances, guaranteeing accurate color reproduction on the final print.

By incorporating these tools and guidelines, you can achieve consistent, professional-quality results where the proof aligns seamlessly with the final printed product.

What is the connection between Fogra standards and ISO 12647 for printing quality?

Fogra standards align with the ISO 12647 guidelines, including ISO 12647-7, which focuses on proofing. These standards help printers and proof providers meet internationally recognized benchmarks for color accuracy and consistency.

Adhering to Fogra standards allows certified providers to ensure dependable proof-to-print matching, delivering consistent, high-quality results across various printing processes.

Related Blog Posts

- How to Ensure Color Accuracy in Proofing

- ISO 2846: Ink Color Standards Explained

- Proofing Standards in Printing: Key ISO Guidelines

- ISO 13655 vs. Other Print Standards

https://app.seobotai.com/banner/banner.js?id=697038c00a871bef4adda7db