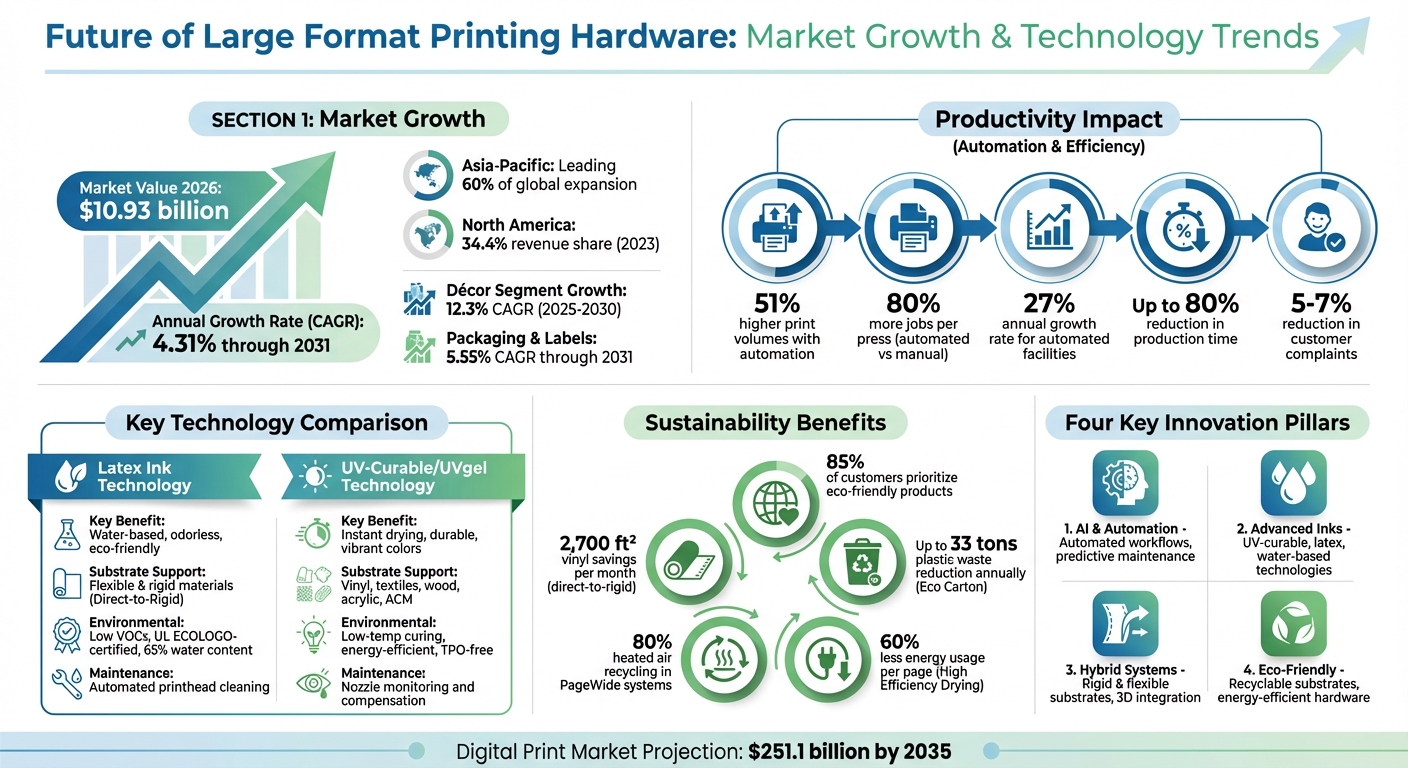

The large format printing industry is evolving with AI integration, eco-conscious solutions, and new ink technologies leading the charge. By 2026, the market is projected to hit $10.93 billion, growing at an annual rate of 4.31% through 2031. Here’s what you need to know:

- AI and Automation: Tasks like color correction and error checking are now automated, reducing production time by up to 80% and increasing efficiency. Tools like HP‘s Auto Alert Agent (AAA) 2.0 and Canon‘s UVgel systems improve quality and reduce waste.

- Advanced Ink Technologies: UV-curable and latex inks are reshaping printing with faster drying, better durability, and lower environmental impact. Canon’s UVgel 860 and HP’s Latex R530 are standout examples.

- Hybrid and 3D Printing: Modern systems handle both rigid and flexible materials, offering textured finishes and multi-layer printing for diverse applications like signage and interior design.

- Eco-Friendly Practices: Water-based inks, recyclable substrates, and energy-efficient hardware are now industry standards, driven by customer demand for sustainable solutions.

- Market Growth: Asia-Pacific leads market expansion, while North America maintains a strong presence. Décor and packaging are among the fastest-growing application segments.

The industry is shifting toward modular hardware, remote management tools, and subscription-based financing models, making upgrades more accessible and future-focused. Print shops leveraging these advancements can reduce costs, improve output, and meet growing customer demands.

Quick Comparison of Key Ink Technologies

| Feature | Latex Ink Technology | UV-Curable / UVgel Technology |

|---|---|---|

| Key Benefit | Water-based, odorless | Instant drying, vibrant colors |

| Substrate Support | Flexible & rigid materials | Vinyl, textiles, wood, acrylic |

| Eco Impact | Low VOCs, recyclable inks | Energy-efficient curing |

| Maintenance | Automated cleaning | Nozzle monitoring |

The future of large format printing lies in speed, efficiency, and sustainability, offering businesses the tools to stay competitive in a rapidly changing market.

Large Format Printing Industry Growth and Technology Trends 2025-2031

What Are The Future Trends In Large Format Printing? – Graphic Design Nerd

Major Technology Developments in Large Format Printing

The landscape of large format printing is evolving at a rapid pace, thanks to advancements in artificial intelligence, ink technologies, and hybrid printing systems. These breakthroughs are redefining quality, reducing manual labor, and broadening the scope of applications – shaping the future of printing hardware.

AI and Automation in Printing Workflows

Artificial intelligence is reshaping every step of the printing process, from preparation to final output. Tasks like error checking, color correction, and layout adjustments, which once required significant manual effort, are now handled in minutes by automated prepress software. Tools like "Preflight" use AI to recommend optimal print modes based on customer needs, while machine-learning algorithms monitor production in real time.

The impact on productivity is undeniable. Print shops leveraging automation report 51% higher print volumes and produce 80% more jobs per press compared to those relying on manual workflows. Automated facilities also experience an average growth rate of 27% annually, far exceeding the industry norm.

Real-time quality control systems, such as HP’s Auto Alert Agent (AAA) 2.0 and Canon’s UVgel DynamicMotion Control, use machine vision to monitor nozzle performance and media alignment. These systems correct errors on the fly, eliminating the need to halt production. For instance, Elanders, a printing company, implemented HP’s AAA 2.0 in March 2024. Andreas Organzidis, Head of Color Digital Printing at Elanders, highlighted its impact:

"By using AAA 2.0, we experience a significant reduction in production time, saving 1 hour for every 80,000 impressions. This not only enhances our operational efficiency but also drastically reduces customer complaints and returns by 5-7%."

- Andreas Organzidis, Head of Color Digital Printing, Elanders

AI-powered tools can cut prepress and production times by up to 80%, with automated color profiling reducing a 50-minute task to under 5 minutes. In industries like architecture and engineering, automation has slashed lead times from three days to just 20 minutes. Additionally, Autonomous Mobile Robots (AMRs), developed with MoviĜo Robotics, now handle media transfers between storage and presses, saving up to two hours per press daily.

Remote management tools like HP PrintOS Production Hub enable operators to oversee production and prioritize urgent tasks from anywhere, addressing challenges like labor shortages. This shift to edge computing ensures real-time error detection and immediate productivity gains without relying on cloud-based systems.

These advancements lay the groundwork for innovations in ink systems that emphasize both efficiency and sustainability.

UV-Curable and Latex Ink Technology

Modern ink technologies are revolutionizing large format printing by enhancing durability, speeding up production, and supporting a wide range of materials – all while addressing environmental concerns.

Canon’s UVgel 860 gel set, introduced in September 2025, delivers odorless, quick-drying prints with exceptional durability. Its FullBeam Curing system, featuring 11-foot-wide LED arrays, ensures consistent light exposure and a wider color range. This technology achieves production speeds of up to 2,271 square feet per hour without compromising quality.

HP’s Latex R530, launched in March 2025, offers a game-changing approach to direct-to-rigid printing. By eliminating the traditional "Print & Mount" process – where vinyl is printed and then manually adhered to rigid boards – it significantly reduces material waste and labor costs. On average, users save approximately 2,700 square feet of self-adhesive vinyl per month.

| Feature | Latex Ink Technology | UV-Curable / UVgel Technology |

|---|---|---|

| Key Benefit | Water-based, odorless, eco-friendly | Instant drying, durable, vibrant colors |

| Substrate Support | Flexible and rigid (Direct-to-Rigid) | Supports vinyl, textiles, wood, acrylic, ACM |

| Environmental | Low VOCs, UL ECOLOGO-certified | Low-temp curing, energy-efficient |

| Maintenance | Automated printhead cleaning | Nozzle monitoring and compensation |

Both systems emphasize sustainability. Latex inks are water-based, odorless, and can include up to 65% reclaimed water in their production. UV-curable technologies use low-temperature curing to cut energy consumption while keeping VOC emissions minimal. This aligns with the growing demand for sustainable practices, as 85% of Print Service Provider customers now prioritize eco-friendly products.

"The HP Latex R530 printer is the only all-in-one compact HP Latex solution, allowing seamless adaptation between rigid and flexible applications."

- Daniel Martinez, Global Head and General Manager, HP Large Format Business

Maintenance has also become more efficient. Automated features like ink recirculation, printhead cleaning, and nozzle performance monitoring reduce downtime and manual intervention. Many systems now offer modular upgrades, such as white ink modules, enabling print shops to expand their capabilities as needed.

Smart Substrates and 3D Printing Integration

The line between traditional large format printing and 3D production is becoming increasingly blurred. Hybrid printing platforms now handle both flexible and rigid materials, with some systems accommodating substrates up to 2 inches thick. This opens up opportunities in areas like interior design, architectural projects, and custom manufacturing.

Canon’s Colorado XL-series, unveiled in September 2025, exemplifies this trend. This hybrid platform, measuring 11 feet wide, incorporates UVgel 860 technology and FLXture for creating textured finishes on rigid materials like ACM panels and polypropylene.

"The 3.2m graphics market is evolving fast, and customers need more than incremental improvements – they need a platform that can truly transform the way they work."

- Kiyoshi Oka, Executive Vice President and General Manager, Canon U.S.A., Inc.

The addition of white ink capabilities on transparent and colored media is unlocking new creative possibilities, enabling multi-layered and dimensional designs. Print shops are also expanding into 3D and "direct-to-shape" printing, offering services beyond flat graphics.

Sustainability continues to drive innovation in substrates. Recyclable options, such as cardboard for trade show displays and PVC-free or paper-based materials, are gaining traction. This shift is especially relevant in the construction sector, which accounts for roughly 40% of energy use in the EU and is increasingly focused on circular, recyclable solutions.

Environmental Considerations in Large Format Printing Hardware

The printing industry faces growing pressure to shrink its environmental footprint, prompting hardware manufacturers to develop solutions that reduce waste, lower emissions, and promote circular systems. With 85% of print service provider customers now prioritizing sustainable products and practices, focusing on environmental performance has shifted from being a bonus to an essential competitive factor. This push for sustainability aligns closely with the technological advancements already shaping the industry.

Eco-Friendly Inks and Recyclable Substrates

The move from solvent-based to water-based inks and UVgel technologies has significantly improved the environmental impact of large format printing. Take HP Latex inks, for instance – they are made of 65% water, contain no solvents, and produce odor-free prints that are safe for indoor environments. These inks boast UL ECOLOGO and UL GREENGUARD Gold certifications, making them ideal for spaces where air quality is a priority.

Canon’s UVgel 860 technology, launched in September 2025, offers another eco-conscious option. Its TPO-free and VCL-free gel inks cure at low temperatures using LED arrays, eliminating the need for high-heat drying and reducing VOC emissions. Additionally, Canon has introduced recyclable UVgel ink bags, packaged in cardboard boxes instead of plastic cartridges, as part of its Colorado XL-series.

HP has taken sustainability a step further with its Eco Carton technology, which swaps out plastic ink cartridges for 100% recyclable cardboard containers. For high-volume operations, this innovation can cut plastic waste by up to 33 tons annually. HP also runs the HP Planet Partners program, a free recycling initiative for used ink bags, printheads, and cartridges, supporting a closed-loop system.

Substrate manufacturers are also stepping up, offering PVC-free alternatives. One example is Xanita aspect, a paper-based board made entirely from post-consumer waste paper. It delivers strong performance without the environmental downsides of traditional plastic-heavy substrates. With the construction sector accounting for about 40% of energy use and 36% of greenhouse gas emissions in the EU, the demand for recyclable materials in building projects continues to grow.

"Sustainability is already affecting your bottom line – whether you realize it or not."

- Richard Bottrill, Head of Engineering and Sustainability, Pearce Signs

Energy-Efficient Printing Equipment

Beyond advancements in inks, hardware innovations are playing a key role in improving environmental efficiency. Modern printers now feature energy-saving technologies, such as ENERGY STAR and EPEAT Gold certifications, along with optimized drying systems and intelligent sleep modes that reduce power consumption during idle times.

HP’s High Efficiency Drying (HED) technology, found in its PageWide systems, recycles up to 80% of heated air, cutting energy use per page by as much as 60%. Canon’s L-COA PRO II image processing engine further boosts efficiency by enabling faster start-up times, reducing energy usage during warm-up or idle periods.

LED curing systems have also made a big impact. Canon’s UVgel FullBeam Curing uses an 11-foot-wide LED array to deliver consistent UV light across the print width while consuming much less energy than traditional mercury vapor lamps. This low-temperature curing method also prevents warping or distortion in heat-sensitive materials, reducing waste.

Automated maintenance features add another layer of sustainability. Systems like automated white ink recirculation minimize sediment buildup, reducing the need for energy-intensive cleaning cycles. This can save print shops approximately 8–10 labor hours per week, translating to over $20,000 in annual labor cost savings, while also cutting down on wasted energy and materials.

Additionally, modular designs like Canon’s Colorado XL-series allow businesses to upgrade features – such as adding white ink capabilities – without replacing entire machines. This approach extends the life of equipment, reduces electronic waste, and supports a more sustainable lifecycle.

"Sustainability is a cornerstone of our business strategy, inspiring us to engineer presses and solutions that maximize product longevity, minimize paper waste, and reduce energy consumption."

- Barbara McManus, Global Head and General Manager of PageWide Industrial, HP Inc.

| Feature | Environmental Benefit | Hardware Example |

|---|---|---|

| Water-Based Inks | 100% solvent-free; safe for indoor use; odorless | HP Latex 630/700/800 Series |

| Eco Carton Technology | Reduces plastic waste by up to 33 tons/year | HP Latex 2700 Series |

| High Efficiency Drying | Up to 60% less energy usage per page | HP PageWide Advantage 2200 |

| UVgel FullBeam Curing | Low-energy LED curing; consistent dosing | Canon Colorado XL-series |

| White Ink Recirculation | Prevents waste and reduces cleaning cycles | HP Latex 800W / 2700W |

For print shops, environmental certifications can open doors to contracts in sectors where sustainability is a top priority. Industries like healthcare, education, and government increasingly require UL GREENGUARD Gold-certified materials, making eco-conscious hardware a valuable business asset. These energy-efficient innovations are paving the way for more sustainable printing practices across the board.

sbb-itb-ce53437

Market Growth and Future Developments

The large format printing hardware market is on a steady growth path. Projections estimate the market will reach between $10.36 billion and $13.48 billion by 2030–2031, with a compound annual growth rate (CAGR) of 3%–5.5%. This growth is fueled by trends like digitized packaging, customized textiles, and eye-catching commercial signage.

The Asia-Pacific region is anticipated to lead the charge, driving approximately 60% of the global market’s expansion through 2029. North America, however, held its ground in 2023, claiming a 34.4% revenue share. Among application segments, décor is expected to grow the fastest, with a projected 12.3% CAGR between 2025 and 2030. Packaging and labels, spurred by e-commerce and the demand for quicker SKU changes, are set to grow at a 5.55% CAGR through 2031.

Ink technology remains a dominant force in the market. Ink-based systems accounted for 61.3% of revenue in 2023 and are projected to capture 91.5% by 2025. Latex inks, in particular, are on track to be the fastest-growing segment, with a 6.05% CAGR through 2031. Their appeal lies in being odor-free, eco-friendly, and eliminating warm-up times. These developments are paving the way for advancements in production inkjet presses.

High-Speed Production Inkjet Presses

High-speed production inkjet presses are becoming a go-to solution for print shops managing high-volume jobs while maintaining quality. These systems offer quick job changeovers and produce results comparable to offset printing, making them a compelling alternative to older solvent-based machines. It’s estimated that high-speed inkjet presses will add an extra 0.9% to the market’s overall CAGR.

Recent product launches highlight the innovation in this space. In April 2025, Konica Minolta unveiled the Accuriolet 30000 B2 HS-UV inkjet press, which features reduced RIP time and automatic double-sided printing. Earlier that year, in January, Canon introduced the imagePROGRAF TZ-5320, capable of printing up to four pages per minute while consuming less energy. These advanced systems support modular workflows and handle a variety of substrates, enabling quicker turnaround times and allowing businesses to diversify without the need for multiple machines. This flexibility is driving essential hardware upgrades.

Hardware Upgrades for Better Output

To stay competitive in an evolving market, print shops are upgrading their hardware. Switching to UV-curable or latex systems eliminates the need for volatile solvents, enabling immediate curing and reducing finishing times. This shift boosts production efficiency and throughput.

Take, for example, OK To Colour, a print services provider in the UK. They upgraded to the Canon Colorado M3W, a roll-to-roll UVgel printer. This move enhanced automation, minimized maintenance, and reduced turnaround times, enabling the company to handle larger volumes with ease. Similarly, Simpsons Printing adopted the Fujifilm Acuity Prime LED flatbed printer, bringing production in-house. This upgrade not only lowered outsourcing costs but also improved efficiency for high-volume banner orders.

Subscription-based financing models are also making these upgrades more accessible. Companies like Ricoh and Epson now offer leasing options that spread the cost of industrial printers – ranging from $100,000 to $500,000 – over several years. Considering that annual operating expenses, including ink, service, and energy, can account for up to 40% of the initial hardware cost, these financing options provide a practical way to manage cash flow during upgrades.

AI-powered hardware is another game-changer. Systems integrated with platforms like HP PrintOS offer predictive maintenance and automated job routing, which can cut operating costs by 10% to 35%. Remote diagnostics and monitoring further reduce expenses by up to 25%, minimizing unplanned downtime and extending equipment lifespan. These advancements are helping businesses maximize the value of their investments while staying ahead in the competitive printing market.

How Advanced Hardware Benefits Print Shops

Modern hardware is reshaping the print industry, making operations smoother and opening doors to new opportunities. Upgrading from older equipment to advanced systems allows print shops to offer more services, improve workflows, and boost profitability.

More Customization and Flexibility

With today’s technology, print shops can tackle projects that used to require multiple machines or outsourcing. Hybrid printers like the Canon Colorado XL and HP Latex R530 handle both rigid materials – such as foam board, acrylic, and wood – and flexible substrates like vinyl and fabric.

Advanced ink systems also bring exciting possibilities. For instance, white ink allows printing on transparent, colored, or metallic surfaces. On top of that, printers now support specialty media like Washi, bamboo, and thick fine art paper. This means print shops can offer unique, high-end products that stand out. Aaron Brill, Product Manager at Epson America, Inc., highlights this advantage:

"Specialty media can take a print project from basic to extraordinary, bringing out vibrant colors and transforming it into a visually striking and impactful print."

Innovative features like "FLXture" can replicate textures like leather, wood, or fabric, while "FLXfinish" lets operators switch between matte and gloss effects without changing inks or media. For short-run jobs, digital printers are a game-changer, eliminating expensive setup processes and making on-demand projects more affordable. This is especially beneficial for clients needing quick, localized campaigns.

Better Business Efficiency and Customer Satisfaction

Advanced hardware doesn’t just expand creative possibilities – it also makes day-to-day operations more efficient. Automated systems help reduce labor costs, minimize errors, and speed up production. Features like AI-powered nozzle monitoring, automated media tracking, and self-correcting color management cut down on downtime and material waste. In fact, modern printers can often be managed by a single operator, helping businesses navigate labor shortages.

These improvements are driving growth. For example, Elanders, a global printing company, adopted HP’s AAA 2.0 machine-learning algorithm in March 2024. Andreas Organzidis, Head of Color Digital Printing at Elanders, shared their experience:

"By using AAA 2.0 we experience a significant reduction in production time, saving 1 hour for every 80,000 impressions. This not only enhances our operational efficiency, but also drastically reduces customer complaints and returns by 5-7%."

Speed is another key factor. Advanced ink systems like Epson UltraChrome GS3 enable same-day lamination, meeting the increasing demand for fast turnarounds. Direct-to-rigid printing eliminates the need for the traditional "Print & Mount" process, saving about 2,700 ft² of self-adhesive vinyl per month while cutting costs and waste. David Bistrovic, Product Manager at Epson America, Inc., underscores the importance of speed:

"In a sign shop, speed isn’t just about quick printing, it’s the backbone of efficiency. Faster output means jobs move through the print process efficiently, giving shops the ability to meet deadlines, handle high-volume orders and potentially acquire additional business."

These advancements also align with the industry’s push toward sustainability and smarter automation.

Case Study: Technology at Miro Printing & Graphics Inc.

The benefits of advanced hardware are evident in real-world applications. Take Miro Printing & Graphics Inc. in Hackensack, NJ, for example. This full-service print shop uses cutting-edge equipment to produce a wide range of high-quality products. Their large-format printing capabilities include banners, posters, and custom signage, while their in-house bindery services handle cutting, folding, and binding.

Miro’s setup allows them to choose between digital and offset printing, ensuring the most efficient method is used for each project. For large-format jobs, they produce items like car magnets and door hangers, taking full advantage of modern substrate and ink technologies. Their ability to handle both standard and custom projects showcases the versatility of today’s printing systems.

Preparing for the Future of Printing

The large format printing industry is undergoing rapid changes, and keeping up means adopting the technologies that are reshaping the landscape. The digital print market is projected to reach $251.1 billion by 2035, a nearly 50% increase compared to 2025. Companies investing in advanced hardware now will be better positioned to capture market share, while those that hesitate may find themselves outpaced by competitors already leveraging high-productivity equipment. These shifts highlight the growing importance of AI-driven solutions.

AI and automation are no longer optional – they’re essential. Jordan Gorski, Vice President of Global Standards and Certifications at PRINTING United Alliance, emphasizes this point:

"Automation in print is no longer a luxury – it’s a necessity"

With tools like predictive maintenance and real-time error detection, print shops can streamline operations, allowing smaller teams to handle larger workloads with greater efficiency.

Sustainability, once a differentiator, is now an expectation. Customers increasingly demand eco-friendly practices, making it crucial to upgrade to hardware that supports water-based latex inks and recyclable substrates. Offering environmentally responsible options without sacrificing quality or speed gives print shops a clear edge in a competitive market.

To stay ahead, print shops must focus on future-proofing their operations. Modular, field-upgradable platforms are a smart solution, enabling businesses to add capabilities as needed without incurring significant upfront costs. This flexibility allows them to adapt quickly to shifting market demands.

Additionally, adopting standardized color management systems, such as G7 or G7+ certification, ensures consistent output – something that’s often required by major brands. Integrating web-to-print portals and remote monitoring solutions is also key to meeting customer expectations, especially as the global web-to-print market is expected to approach $40 billion by 2027.

FAQs

How is AI transforming large format printing for better efficiency?

AI is transforming the world of large format printing by automating essential processes, cutting down on manual labor, and boosting efficiency across the board. With features like predictive insights, proactive maintenance, and optimized print settings, AI helps create smarter workflows. The result? Less downtime and consistently high-quality prints.

AI-powered tools are also simplifying prepress tasks, such as spotting errors, correcting colors, and fine-tuning layouts. This not only speeds up production but also reduces waste. These advancements are making large format printing faster, more dependable, and better tailored to meet customer expectations – paving the way for exciting progress in the industry.

What are the environmental advantages of modern ink technologies in large format printing?

Modern advancements in ink technology for large format printing are making strides toward being more environmentally friendly by focusing on sustainability and safety. For instance, water-based inks are gaining popularity as they emit fewer harmful chemicals compared to traditional solvent or UV-based inks. This shift not only benefits the environment but also promotes better health by steering clear of hazardous substances like heavy metals and phthalates.

On top of that, newer ink formulations allow for the use of PVC-free, eco-conscious materials that align with strict environmental regulations. These improvements are helping the printing industry shrink its ecological impact while addressing the increasing demand for greener solutions. With these innovations, the industry is taking meaningful steps toward adopting more responsible and sustainable practices.

Why is the Asia-Pacific region experiencing rapid growth in the large format printing market?

The Asia-Pacific region is experiencing rapid growth in the large format printing market, thanks to its fast-growing economies and expanding industrial sectors. This surge is largely driven by the rising need for signage, packaging solutions, and advertising materials, especially in countries undergoing significant urbanization and large-scale infrastructure development.

On top of that, advancements in printing technologies, such as UV-curable inks, are transforming the industry. The presence of leading manufacturers like Seiko Epson, Canon, and Fujifilm is also pushing innovation and making these technologies more accessible. These elements position Asia-Pacific as a major force in shaping the future of large format printing.

Related Blog Posts

- How Automation Improves Print Turnaround Times

- Ultimate Guide to Large Format Print Durability

- 3D Printing Trends in Commercial Printing

- Complete Guide to Print Workflow Automation Tools

https://app.seobotai.com/banner/banner.js?id=69755eac12006df3517a0002