When printing large format projects, choosing the right substrate – materials like vinyl, paper, or acrylic – directly impacts durability, cost, and performance. Outdoor prints typically last 3–5 years, depending on factors like ink type, UV exposure, and protective coatings. Adding laminates can extend lifespan by up to 50%. For long-term use, materials like cast vinyl or aluminum composites are recommended, while short-term indoor projects can rely on affordable options like paper or foamcore. Proper storage, installation, and maintenance play a key role in maximizing durability. Below, we explore the factors affecting substrate longevity and practical tips to ensure your prints stand the test of time.

Factors That Affect Substrate Lifespan

The lifespan of printed substrates hinges on three main factors: environmental exposure, ink compatibility, and protective finishes. Each plays a critical role in determining durability, influencing everything from material selection to installation and maintenance practices.

Environmental Exposure

Sunlight, temperature changes, and moisture are some of the biggest culprits behind print degradation. UV radiation, for example, triggers photooxidation, causing prints to fade, yellow, and become brittle over time. South-facing graphics, which receive the most sunlight, deteriorate faster compared to their north-facing counterparts.

"Length and intensity of UV radiation in sunlight is a decisive aging factor for prints." – Sonja Angerer, FESPA

Temperature swings are another concern. The constant expansion and contraction caused by fluctuating temperatures can lead to warping, peeling, and cracking. High heat accelerates the chemical breakdown of pigments, while moisture infiltrates behind substrates, weakening adhesion – especially on uneven surfaces. Other environmental factors like wind, hail, and even oils from human touch gradually erode ink and damage the substrate surface.

Outdoor conditions are significantly harsher than indoor environments. Standard outdoor prints using Eco-Solvent or Latex inks last around three years. UV-curable inks extend this to 3–5 years, and with proper laminates, prints can endure for 7–10 years.

Environmental factors aside, the compatibility between ink and substrate is equally vital for long-lasting prints.

Ink and Printing Technology Compatibility

Choosing the right ink for your substrate can make all the difference. UV-curable inks, for instance, create cross-linked polymer networks that bond directly to materials like acrylic and PVC. This results in a surface highly resistant to chemical damage and mechanical wear – far outperforming traditional solvent-based inks.

Flexibility matters too. Using rigid UV ink on flexible materials like banners can cause cracking and peeling in just weeks. Conversely, soft UV ink is ideal for stretchable materials like leather or vinyl. Surface characteristics also come into play – porous materials like wood form strong mechanical bonds with ink, while non-porous surfaces like glass or metal often require adhesion promoters or primers to ensure durability.

"We’ve seen clients try to use a rigid ink on a flexible banner, and the result is a cracked, peeling mess within weeks." – Refinecolor

When it comes to outdoor signage, pigment-based inks are a better choice than dye-based ones. Pigments provide a physical barrier against UV radiation, offering superior lightfastness. For professional-grade prints, the Blue Wool Scale – a measure of lightfastness – recommends a rating of 5 to 8 for outdoor durability.

To further protect prints, applying a proper finish is essential.

Finishing and Protective Coatings

A protective coating serves as a first line of defense, shielding prints from UV rays, scratches, and general wear. Overlaminates, for example, can extend the lifespan of graphics by up to 50%. These coatings protect both the ink and substrate from environmental damage, including rain, dirt, and dust.

Material compatibility is key. For instance, a vinyl overlaminate should be used with a vinyl substrate to ensure both materials expand and contract at the same rate, preventing peeling or failure. For floor graphics, thicker textured films (around 5-mil) offer slip resistance and durability. They typically last 3 months to a year outdoors and up to 3 years indoors, depending on foot traffic.

A real-world example highlights the importance of protective finishes. In August 2020, The Salty Bean café in Clearwater, FL, replaced a faded sign with a 4’x8′ aluminum composite panel printed with premium marine-grade UV ink and coated with a 2K automotive-grade clear coat. As of October 2025, the sign remains intact despite high UV exposure and salt spray, while an unlaminated version failed within just 12 months.

"For ultimate longevity in harsh environments, nothing beats a post-print protective coating, like a clear varnish or laminate. This acts as a sacrificial layer that absorbs UV damage and abrasion." – Refinecolor-Eason

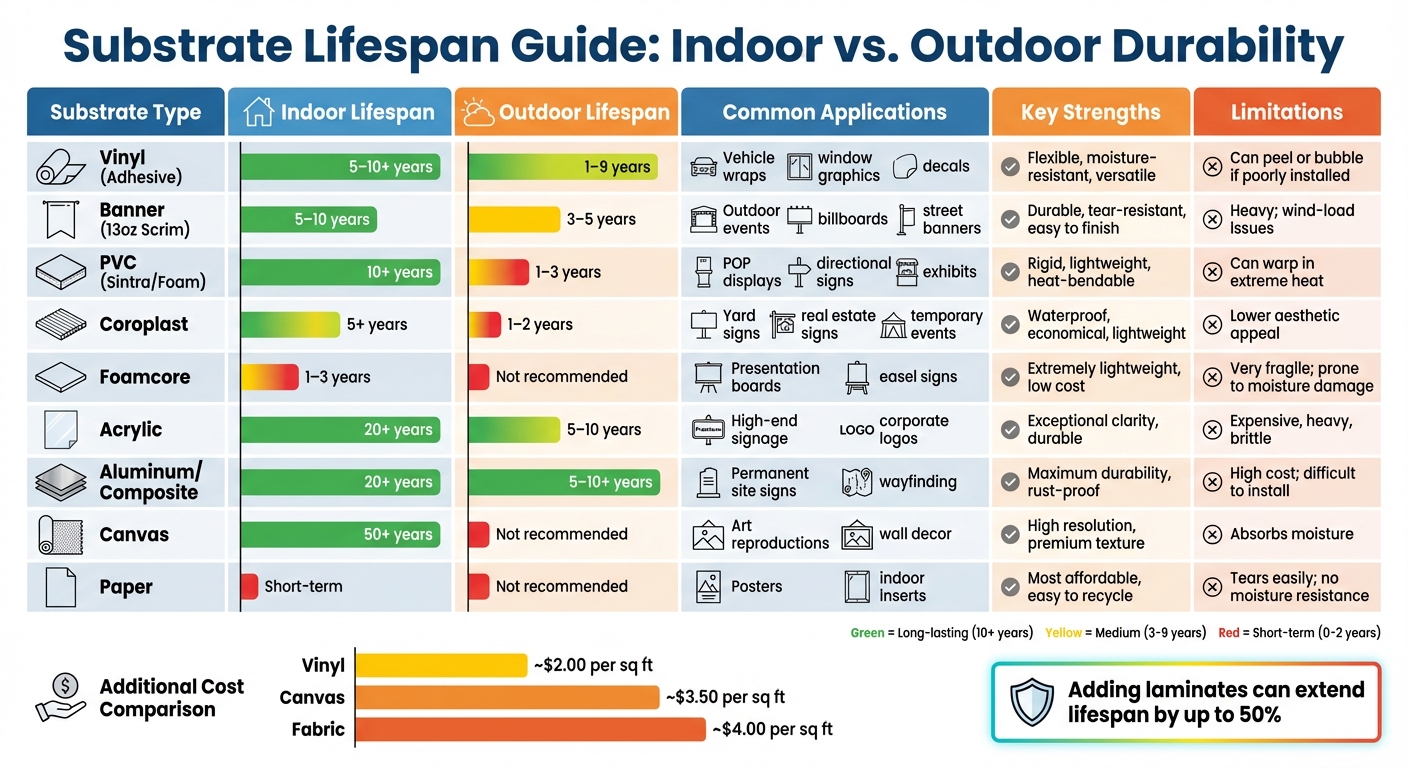

Common Substrates and Expected Lifespans

Large Format Printing Substrate Lifespan Comparison Chart

Large format substrates generally fall into two categories: roll-fed materials (like vinyl, banner, and canvas) and rigid boards (such as PVC, acrylic, and aluminum). Each type has unique durability characteristics that determine how well they perform in different display environments.

When it comes to longevity, where the substrate is used makes a big difference. Indoor displays, protected from sunlight and harsh weather, can last for decades, even centuries. Outdoor prints, on the other hand, typically endure around five years unless they’re laminated for added protection.

For outdoor use, cast vinyl is a top choice, offering a lifespan of 7–10 years. It’s stable, flexible, and designed to withstand long-term exposure to the elements. Calendered vinyl, while more affordable, is better suited for short-to-medium-term applications, lasting about 3–5 years. However, it’s thicker and more prone to shrinkage when exposed to heat.

"There are no ‘good’ or ‘bad’ SAVs. We could say, rather, that there is a more appropriate type of SAV for each application type." – HP-Alvaro, HP Latex Knowledge Center

Substrate Type Comparison

| Substrate Type | Indoor Lifespan | Outdoor Lifespan | Common Applications | Strengths | Limitations |

|---|---|---|---|---|---|

| Vinyl (Adhesive) | 5–10+ years | 1–9 years | Vehicle wraps, window graphics, decals | Flexible, moisture-resistant, versatile | Can peel or bubble if poorly installed |

| Banner (13oz Scrim) | 5–10 years | 3–5 years | Outdoor events, billboards, street banners | Durable, tear-resistant, easy to finish | Heavy; wind-load issues (unless mesh) |

| PVC (Sintra/Foam) | 10+ years | 1–3 years (Outdoor grade) | POP displays, directional signs, exhibits | Rigid, lightweight, heat-bendable | Can warp in extreme heat; outdoor life is limited |

| Coroplast | 5+ years | 1–2 years | Yard signs, real estate signs, temporary events | Waterproof, economical, lightweight | Ribbed texture; lower aesthetic appeal |

| Foamcore | 1–3 years | Not recommended | Presentation boards, easel signs | Extremely lightweight, low cost | Very fragile; prone to denting and moisture damage |

| Acrylic | 20+ years | 5–10 years | High-end signage, corporate logos | Exceptional clarity, durable, "pop" effect | Expensive, heavy, can be brittle |

| Aluminum/Composite | 20+ years | 5–10+ years | Permanent site signs, wayfinding | Maximum durability, rust-proof | High cost; difficult to transport/install |

| Canvas | 50+ years | Not recommended | Art reproductions, wall decor | High resolution, premium texture | Expensive; absorbs moisture |

| Paper | Short-term/Temporary | Not recommended | Posters, indoor inserts | Most affordable, easy to recycle | Tears easily; no moisture resistance |

Choosing the right material involves balancing durability with cost. For instance, vinyl is an economical option at around $2.00 per square foot, while canvas costs roughly $3.50 per square foot, and fabric comes in at about $4.00 per square foot. Indoors, foamcore is a budget-friendly choice, while aluminum composites are ideal for outdoor applications requiring long-term durability.

How to Extend Substrate Lifespan

Choosing the Right Material

Selecting the appropriate substrate is key to ensuring durability and performance. Substrates are generally categorized by their lifespan: short-term (up to 6 months), medium-term (2–3 years), and long-term (5+ years). For indoor displays, where conditions are controlled, materials can last for decades. Outdoor substrates, however, need to withstand harsh elements like UV rays, rain, and temperature fluctuations. In areas with high foot traffic, where people may touch the graphics, oils from hands can degrade the ink. To counter this, use substrates with protective coatings or laminates.

The composition of the material also plays a significant role. Cast vinyl, for example, is produced without mechanical stress, making it more stable and durable compared to calendared vinyl, which can shrink when exposed to heat due to stress from its manufacturing process. Cast vinyl is particularly suited for vehicle wraps and surfaces with tight curves, as it resists cracking and pulling away when stretched. Meanwhile, monomeric vinyl, with its low-molecular-weight plasticizers, is suitable for outdoor use for up to 3 years, whereas polymeric vinyl provides better chemical stability, lasting 5–7 years.

Adding a protective layer like an overlaminate can significantly extend a graphic’s lifespan – by as much as 50%. It’s important to match materials, such as using vinyl laminate on vinyl substrates, to ensure both layers expand and contract at the same rate, avoiding delamination. Graphics printed with Eco-Solvent or Latex inks typically last about 3 years outdoors, but with the right laminates or varnishes, their lifespan can be stretched to up to 7 years.

Once you’ve chosen the right materials and protective layers, proper installation techniques become crucial to maximizing longevity.

Installation and Removal Techniques

Good installation practices can make all the difference in how long a substrate lasts. Ensuring surface compatibility is critical – on uneven surfaces like brick, concrete, or wood, moisture can seep behind the substrate, leading to adhesive failure. For transparent substrates, second surface printing (printing on the reverse side) can protect the ink from wear caused by touch, oils, or cleaning products.

The orientation of installation also matters. Horizontal or angled mounting exposes graphics to more UV rays and pollutants, reducing their lifespan compared to vertical mounting. Indoors, graphics should be placed away from heating or air conditioning vents, as fluctuating temperatures can cause repeated expansion and contraction, leading to warping or peeling.

For urban outdoor setups, using anti-graffiti films can protect graphics from vandalism. When cleaning, avoid harsh chemical solvents unless specifically recommended, as they can speed up the degradation of both the ink and the substrate.

Beyond material and installation choices, there are environmentally conscious options that balance durability with sustainability.

Eco-Friendly Material Options

Sustainable substrates offer a way to reduce environmental impact without compromising on durability. PVC-free options, such as blockout banners, pole banners, and various wallpapers with non-woven or suede finishes, are increasingly popular. There are also recycled content substrates, like adhesive fabrics and satin canvases made from recycled PET resin. Some HP recycled adhesive fabrics, for instance, contain up to 72% recycled content by weight when the liner is included.

For floor graphics, linoleum – made from natural materials like linseed oil and pine rosin – provides a bio-based alternative with an impressive lifespan of 20 to 40 years, outlasting traditional PVC flooring, which typically lasts 10 to 20 years. Cellulose-based materials, such as paper and cardboard, are also durable in extreme temperatures because they expand and contract less than plastics.

"Linoleum’s biodegradable nature makes it an eco-friendly option that breaks down naturally, unlike PVC, which can linger for decades and complicate recycling efforts." – Plastic Practical

For outdoor eco-friendly prints, applying UV-protective laminates or varnishes can extend their lifespan to up to 7 years. Many papers, including bond and coated varieties, as well as photo-realistic poster papers, are compatible with recycling programs, though it’s always a good idea to check local guidelines.

sbb-itb-ce53437

Maintenance and Storage Guidelines

Cleaning and Inspecting Outdoor Prints

To keep outdoor prints in good condition, clean them regularly using mild water and a soft cloth. This helps remove dirt and reduces the impact of UV exposure, which can speed up the wear and tear of both the ink and substrate – especially for south-facing installations. These cleaning habits support the durability measures taken during installation.

Keep an eye on your prints for signs of weather damage, like cracking, bubbling, or color changes (such as yellowing or greying), particularly after extreme weather events like hailstorms or heatwaves. Heavy rain can wear down edges or allow moisture to seep behind substrates, especially on uneven surfaces like brick or concrete, which can lead to adhesive failure. In urban settings, air pollutants and particulate matter can chemically affect the prints, making regular inspections even more important.

Storage Conditions for Unused Materials

Always store substrates in their original packaging to shield them from moisture, dust, and other contaminants. Place them in a clean, dry area, away from direct sunlight, heat sources, or strong UV light, as these can cause fading and make the material brittle over time. Keep the relative humidity below 65%, as higher levels (above 80%) can cause noticeable ink bleed within just 24 hours.

"DO keep the paper in its original packaging until required. This will ensure the product stays clean and is not exposed to excess moisture or other airborne contaminants." – Moab Paper

When handling materials, touch only the edges or underside to avoid transferring oils from your skin, which can affect the coating and reduce print quality. It’s best to wear nitrile gloves instead of cotton ones – they fit better, don’t snag, and offer better protection against contaminants. Avoid stacking prints directly on top of one another or rolling them, as this can strain the surface and lead to cracking or delamination. Use archival interleaving sheets between stored prints to prevent them from sticking together or altering their surface gloss.

Proper storage ensures that materials maintain their quality until you’re ready to apply post-print protection.

Applying Protective Coatings After Printing

Adding laminates or varnishes can significantly extend the lifespan of outdoor prints, from roughly 3 years to as long as 7 years. Film laminates not only offer UV protection but also act as a physical shield against scratches, making them ideal for outdoor graphics and frequently touched indoor displays. For transparent materials, second surface printing is a smart choice, as the substrate itself protects the print.

"We always recommend using a laminate for graphics that will be displayed for longer than six months and for all outdoor graphics regardless of the intended lifespan." – Infinity Images

When applying spray coatings, ensure the environment is between 55°F and 75°F with humidity below 60% to prevent a chalky finish. In cities, anti-graffiti films can be a practical solution to guard against permanent stains from vandalism. Always check that the coating is compatible with the substrate, as some materials may not adhere well to specific protective layers.

Conclusion

Getting the most out of your printed materials starts with smart choices – selecting the right substrates and maintaining them properly. For outdoor projects, vinyl is a reliable option, while protective coatings and controlled storage conditions help reduce the risk of costly reprints and maintain a polished appearance. These steps lay the groundwork for effective upkeep, ensuring your investment stays protected.

The right materials and treatments can make a noticeable difference. For example, using a suitable overlaminate can extend a graphic’s lifespan by up to 50%. Matching ink technology to the substrate prevents fading, with indoor displays using premium systems resisting fading for over 200 years, while outdoor prints with proper UV protection typically last 3 to 5 years.

Environmental factors like UV exposure, humidity, and temperature swings also heavily influence durability. South-facing graphics, for instance, are more prone to UV damage. Proper storage – ideally at around 50% relative humidity – helps prevent issues like ink bleed or material warping. Paying attention to these details can mean the difference between a long-lasting project and one that falls short.

Routine maintenance is equally important. Gentle cleaning and inspections after harsh weather can prevent early wear and tear. When paired with protective laminates and careful installation, these practices ensure your graphics retain their visual appeal and structural integrity over time.

For expert help with choosing durable materials and extending the life of your large format prints, Miro Printing & Graphics Inc. offers not only top-tier printing services but also personalized advice tailored to your project’s needs and environmental conditions. Reach out to Miro Printing & Graphics Inc. for reliable solutions and professional guidance.

FAQs

How do factors like sunlight and temperature impact the lifespan of printing substrates?

Environmental elements, such as UV rays and temperature fluctuations, heavily influence the lifespan of a substrate. Extended exposure to sunlight can cause ink to fade and degrade the material itself by breaking down its polymer structure. For outdoor use, this typically limits the longevity of printed materials to about 5–10 years.

Heat or frequent temperature swings can speed up chemical breakdown, leading to brittleness, yellowing, or moisture damage. To help materials last longer, consider applying UV-resistant coatings and storing them in stable, climate-controlled spaces whenever possible.

How can I make my outdoor large-format prints last longer?

To make your outdoor large-format prints last longer, start by selecting materials that can handle the elements and adding protective measures. Use pigment-based or UV-curable inks, as they offer excellent resistance to UV rays. Pair these with a high-quality UV-protective laminate to guard against fading and weather-related wear. For the base, choose durable options like polyester film, PVC, or acrylic board to ensure your prints hold up over time.

Installation and upkeep are just as important. Place prints in shaded spots to reduce direct sunlight exposure, and avoid areas where they might be subjected to standing water or heavy foot traffic. Clean them carefully using a mild, non-solvent cleaner to avoid scratches or chemical damage. In tougher climates, applying a protective varnish or clear coat can add an extra layer of defense. At Miro Printing & Graphics Inc., we use top-tier inks, weather-resistant materials, and custom laminates to keep your outdoor prints vibrant and durable for years to come.

Why is it important to use ink that’s compatible with your substrate in large format printing?

In large-format printing, using ink that works well with your specific substrate is key to getting top-notch results. The right ink ensures good adhesion, bright and accurate colors, and protection against fading, wear, or external damage.

If the ink and substrate aren’t a good match, you could face issues like weak durability, uneven color quality, or even early signs of deterioration – all of which can hurt the appearance and longevity of your project.

Related Blog Posts

- Substrate Selection for Digital Printing

- Ultimate Guide to Large Format Print Durability

- Lightfastness Testing for CMYK Prints

- Weather-Resistant Textiles for Large-Format Printing

https://app.seobotai.com/banner/banner.js?id=6966c8fa12e0ddc1252f08d1