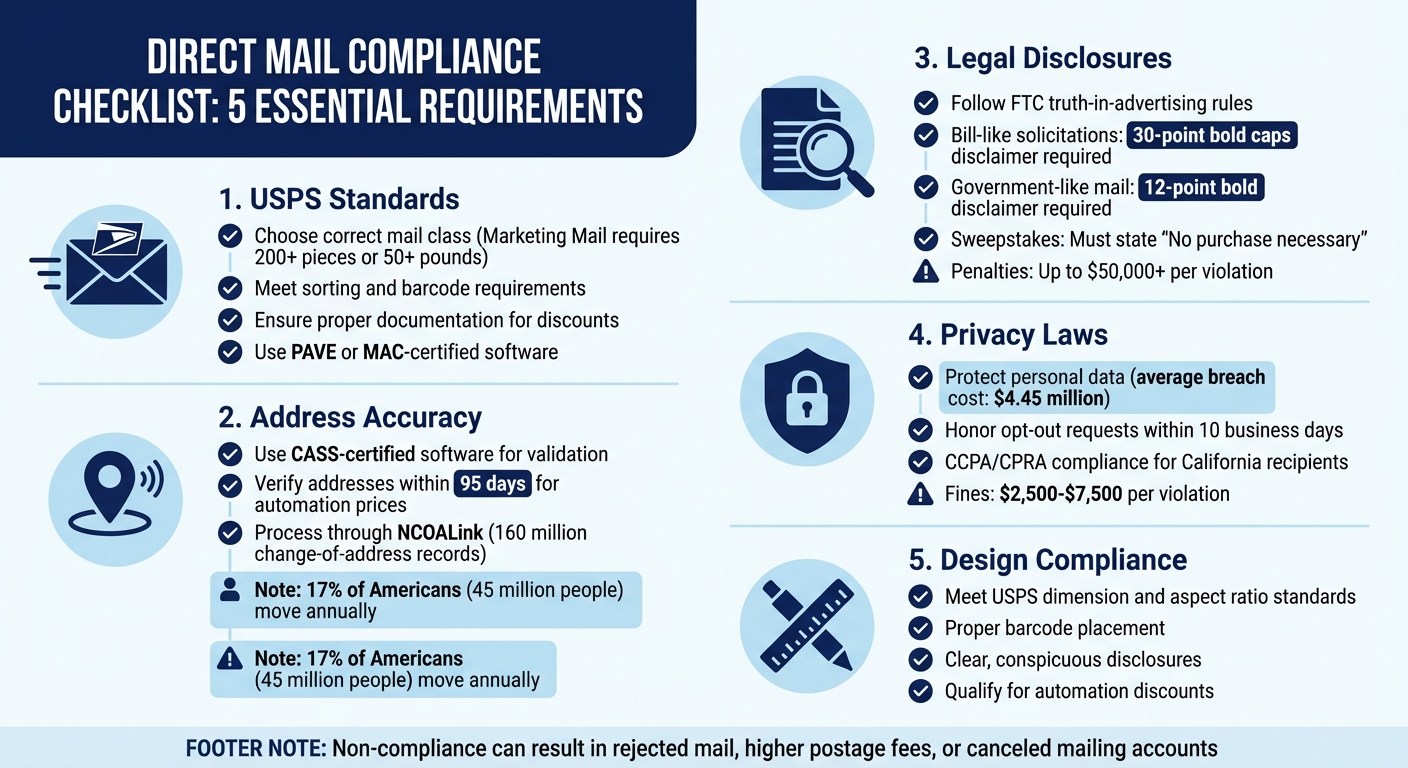

Direct mail compliance ensures your mail reaches recipients without delays or extra costs. Non-compliance can lead to rejected mail, higher postage fees, or even canceled mailing accounts. Here’s what you need to know:

- USPS Standards: Choose the correct mail class (e.g., Marketing Mail, First-Class Mail), meet sorting and barcode requirements, and ensure proper documentation for discounts.

- Address Accuracy: Use CASS-certified software to validate addresses and comply with Move Update requirements, reducing undeliverable mail.

- Legal Disclosures: Follow FTC rules for truthful advertising and include required disclaimers for solicitations, sweepstakes, or government-like mail.

- Privacy Laws: Protect personal data, honor opt-out requests, and comply with laws like California’s CCPA/CPRA.

- Design Compliance: Ensure mailpiece dimensions, barcodes, and content meet USPS standards to avoid penalties or processing issues.

Direct Mail Compliance Checklist: 5 Essential Requirements

USPS Regulations and Mailing Standards

USPS regulations are the backbone of any compliant direct mail campaign. From choosing the right mail class to ensuring proper sorting and documentation, these rules dictate not only whether your mail reaches its destination but also how much you’ll spend on postage.

Mail Classes and Permits

Choosing the right mail class is crucial because it impacts both cost and delivery speed. USPS Marketing Mail is the go-to option for sending printed materials like flyers, newsletters, catalogs, and ads. It’s a cost-effective choice, but it comes with specific requirements: a minimum of 200 pieces or 50 pounds per mailing, with each piece weighing less than 16 ounces. Keep in mind, this class is strictly for domestic mail and cannot be used for international deliveries.

For mail that’s more personal, like invoices or correspondence, First-Class Mail is often required. While it’s pricier than Marketing Mail, it offers faster delivery and includes perks like automatic forwarding and return services. Marketing Mail doesn’t include these services unless you specifically add ancillary service endorsements, which come at an extra cost.

If you’re a small business aiming to reach specific neighborhoods, Every Door Direct Mail (EDDM) is a practical option within the Marketing Mail category. EDDM lets you target geographic areas without needing a mailing list or a permit imprint, making it a simple and efficient choice. Other mail classes include Periodicals, which are reserved for authorized publications like newspapers and magazines, and Package Services and USPS Ground Advantage, designed for larger parcels and items.

Postage Rates and Automation Discounts

Postage rates are heavily influenced by how well your mail is sorted. The more precise the sortation, the better the discount. For example, mail sorted to the 5-Digit level gets the highest discounts, while less refined levels, like Mixed AADC (Automated Area Distribution Center), result in higher rates. To qualify for these automation discounts, your mail must meet USPS barcoding standards and include presort and price documentation generated by PAVE-certified or MAC-certified software.

Mailpieces must also adhere to USPS dimension and aspect ratio standards to qualify for machinable or automated rates, which are far cheaper than nonmachinable rates. Using certified software ensures your documentation complies with USPS formats – this is a non-negotiable requirement for claiming automation discounts. For large mailings, specifically those with 10,000 pieces or more, presort and price documentation is mandatory, even if each piece has postage affixed.

For added efficiency, the Full-Service Automation option requires submitting postage statements and mailing documentation electronically through the PostalOne! system. This simplifies the acceptance process while ensuring compliance with USPS verification standards.

Required USPS Documentation

Proper documentation is essential to support discount claims and ensure compliance. Always include a completed electronic postage statement when claiming discounts or using a permit imprint. This statement must detail how the mail was prepared, the price levels applied, the volume of mail, and the associated postage data.

A USPS Qualification Report is also required. This report should include key details such as the mailer’s name, mailing ID code, processing date, mail class, and the DMM (Domestic Mail Manual) standard used for preparation. For bundled mail, make sure all pieces are “faced” – arranged so that addresses are visible and oriented in the same direction.

It’s important to keep detailed records to back up your claims. For example, publishers sending Periodicals need to maintain entry listings for at least two months after mailing to validate In-County and Outside-County price claims. If your documentation is incomplete or doesn’t allow for verification, the USPS can refuse your mailing. Be ready to provide additional information to the postmaster if needed.

Address List Compliance and Validation

When it comes to direct mail, accuracy isn’t just a nice-to-have – it’s a must. Following USPS regulations for mail classes and documentation is just the start. Ensuring your address list is clean and up-to-date is critical for success. The USPS enforces strict standards for address accuracy, and failing to meet these can lead to losing discounts, higher postage costs, or even wasted mail that never reaches its destination. To stay on track, it’s essential to follow guidelines for recipient consent and regularly update your mailing list to align with USPS standards.

CASS Certification and Address Verification

The Coding Accuracy Support System (CASS) is the USPS’s tool for verifying address accuracy. Using CASS-certified software allows you to check your addresses against the USPS database, which is essential if you’re claiming presorted or automation rates. Here’s how often you need to verify:

- Presorted rates: 5-digit ZIP Codes must be verified within 12 months before mailing.

- Automation prices: Complete addresses need verification within 95 days.

- Carrier route codes: These require updates within 90 days of the mailing date.

These timelines also tie into the USPS Move Update Requirements, which help keep your list current and compliant.

If you’re buying or renting a mailing list, check its National Deliverability Index (NDI) to understand what percentage of the addresses are deliverable. For targeted campaigns, aim for as close to 100% as possible. For smaller lists, you can manually verify addresses using the USPS website or Publication 65, but this approach isn’t practical for large-scale campaigns.

Do Not Mail Lists and Consent Requirements

People have the legal right to opt out of receiving unwanted mail, and ignoring their requests can hurt both your budget and your reputation. The USPS has specific rules for "Pandering Advertisements" (DMM 508.10) and "Sexually Oriented Advertisements" (DMM 508.11), which allow recipients to block certain types of mail. Honoring removal requests isn’t just good practice – it’s essential to avoid unnecessary postage costs and maintain trust with your audience.

To prevent mailing to outdated or incorrect addresses, rely on NCOALink. This database includes roughly 160 million permanent change-of-address records. Processing your list through NCOALink ensures you’re not wasting resources on mail that won’t reach its destination.

USPS Move Update Requirements

Keeping your address list up-to-date is no small task, especially when you consider that 17% of Americans move each year – that’s about 45 million people annually. The USPS Move Update standard is designed to help mailers stay ahead of these changes. For discounted First-Class Mail and USPS Marketing Mail, addresses must be updated within 95 days before mailing.

"The Move Update standard is a means of reducing the number of mailpieces in a mailing that require forwarding or return by the periodic matching of a mailer’s address records with change-of-address orders received and maintained by the Postal Service." – USPS

There are a few ways to meet this requirement. Pre-mailing methods like NCOALink are particularly effective for first-time mailings to addresses you haven’t recently verified. If you mail to your list at least once every 95 days, you can use post-mailing options like Address Change Service (ACS) or Ancillary Service Endorsements (ASE) to stay compliant. Keep in mind, the Postal Service charges fees for electronic or automated address corrections provided through ACS. However, these fees might be waived if you’re using Full-Service ACS. When you submit your postage statement, your signature confirms that you’ve met both Move Update and ZIP Code accuracy requirements.

Content and Design Compliance

When creating direct mail campaigns, it’s crucial to adhere to strict content and design standards that meet both mailing and legal requirements. After confirming the accuracy of your mailing list, ensure your content complies with legal guidelines. The Federal Trade Commission (FTC) enforces rules on truth-in-advertising, which apply to all forms of direct mail. According to the FTC, "Under the Federal Trade Commission Act: Advertising must be truthful and non-deceptive; Advertisers must have evidence to back up their claims; and Advertisements cannot be unfair". This means any claims you make – be it about product benefits, pricing, or performance – must be supported by verifiable evidence before your mail goes out. Additionally, it’s essential to familiarize yourself with the specific rules surrounding advertising claims.

Truthful Advertising Standards

The FTC requires that all claims in your advertising are substantiated and clearly communicated. They assess your mail from the perspective of a "reasonable consumer", considering the overall context, including text, visuals, and layout, to determine the message being conveyed. This includes both explicit statements and implicit messages. For instance, if your mail includes a picture of a complete book set but you’re only offering an abridged version, omitting that detail is considered deceptive. Violations of these standards can be costly, with civil penalties exceeding $50,000 per violation. Further, companies under a cease and desist order risk fines of $53,088 per day, per advertisement for continued violations.

Required Disclosures and Terms

In addition to making accurate claims, some direct mail pieces require specific legal disclosures to clarify the nature of the offer. These disclosures often have strict formatting requirements. For example:

- If your mail resembles a bill or invoice but is actually a solicitation, you must include the following disclaimer in 30-point boldface capital letters:

"THIS IS NOT A BILL. THIS IS A SOLICITATION. YOU ARE UNDER NO OBLIGATION TO PAY THE AMOUNT STATED ABOVE UNLESS YOU ACCEPT THIS OFFER". - Sweepstakes mailings must clearly state: "No purchase necessary" and "A purchase will not increase the odds of winning" in the body text, rules, and entry form.

- If the mailing implies any government affiliation, it must include a disclaimer: "THIS IS NOT A GOVERNMENT DOCUMENT" in 12-point bold type, placed in the upper-right quadrant below the postage.

| Disclosure Category | Text | Size |

|---|---|---|

| Bill-like Solicitations | "THIS IS NOT A BILL. THIS IS A SOLICITATION…" | 30-point bold caps |

| Gov. Connection (Envelope) | "THIS IS NOT A GOVERNMENT DOCUMENT." | 12-point bold caps |

| Sweepstakes | "No purchase necessary"; "Purchase will not increase odds" | Conspicuous (varies) |

| Facsimile Checks | Not a negotiable instrument; No cash value | Must be on face |

Product Representation and Imagery

Your visuals must accurately represent the product or service being advertised. According to the FTC, "An ad is deceptive if it contains a statement – or omits information – that: Is likely to mislead consumers acting reasonably under the circumstances; and Is ‘material’ – that is, important to a consumer’s decision to buy or use the product". Fine print cannot be used to contradict or undermine the primary message of the ad. For instance, a claim like "Lose 10 pounds in one week without dieting" cannot be justified by a small disclaimer stating "Diet and exercise required." Disclosures must be clear and conspicuous, placed near the claims they qualify, and use contrasting colors to ensure readability, even when photocopied.

If your advertising includes claims such as "Made in USA", environmental claims, or health-related statements about supplements or medications, the FTC has additional rules requiring specific evidence to back them up. All visual representations must also align with these claims and be thoroughly supported by documentation.

Privacy and Data Protection

Direct mail campaigns often require collecting, storing, and processing personal information like names, addresses, and purchase histories. Mismanaging this data can lead to serious consequences, including costly breaches. In 2023, the global average cost of a data breach hit $4.45 million. Ensuring compliance in both mailing design and documentation is essential to protect personal data throughout your campaign.

CAN-SPAM Compliance for Digital Elements

If your direct mail campaign includes digital components – like QR codes leading to email sign-ups or follow-up email campaigns – you must comply with the CAN-SPAM Act. This law governs all commercial electronic messages and includes these key requirements:

- Emails must clearly identify as advertisements.

- A valid postal address must be included.

- Recipients must have an easy, single-page option to unsubscribe.

- Opt-out requests must be honored within 10 business days.

- The unsubscribe link must remain active for at least 30 days after the email is sent.

"Each separate email found in violation of the CAN-SPAM Act can result in penalties of up to $53,088." – Federal Trade Commission

If you use third-party services for digital follow-ups, it’s your responsibility to ensure their compliance. Also, avoid offering incentives, such as discounts or coupons, for "forward to a friend" features. Doing so could make your company legally responsible as the sender under CAN-SPAM rules.

CCPA/CPRA Requirements for California Recipients

California’s privacy laws – the CCPA and its amendment, the CPRA – impose strict requirements on businesses. These laws apply to companies that meet specific criteria, such as earning over $26.625 million in gross annual revenue (starting January 1, 2025) or handling the personal information of 100,000 or more California residents. For direct mail campaigns, "personal information" typically includes names and postal addresses.

Under these regulations, California residents have several rights:

- The right to know what data is collected about them.

- The right to request corrections or deletion of their data.

- The right to opt out of the sale or sharing of their personal information.

If you work with third-party mailing services, you must include written agreements prohibiting them from using or disclosing your address lists for purposes beyond the campaign. Failing to include these provisions could classify the sharing of address lists as a "sale" under CPRA. Non-compliance can result in fines of $2,500 per unintentional violation and $7,500 per intentional violation, with each affected consumer considered a separate violation.

Additionally, ensure your website features a "Do Not Sell or Share My Personal Information" link. Online opt-out requests must also align with your physical mailing lists.

Secure Data Storage and Processing

Protecting stored data isn’t just about meeting regulations – it’s a critical practice to prevent breaches. The Federal Trade Commission suggests a five-step approach to data security: "TAKE STOCK. SCALE DOWN. LOCK IT. PITCH IT. PLAN AHEAD.".

- Take Stock: Identify all locations where your address lists are stored – this includes computers, laptops, flash drives, digital copiers, and even file cabinets.

- Scale Down: Only collect and retain the data necessary for your campaign, and limit employee access to those who genuinely need it.

- Lock It: Store paper records in locked cabinets or secure rooms. For electronic data, use encryption (e.g., Transport Layer Security) during storage and transmission. Avoid sending address lists unencrypted and implement multi-factor authentication for remote access.

- Pitch It: When data is no longer needed, securely dispose of it. Shred or burn paper records and use data wipe utilities to permanently erase digital files before discarding hardware.

- Plan Ahead: Before outsourcing, vet the security measures of your mailing service. Include strict contractual requirements, and verify compliance through audits or site visits.

sbb-itb-ce53437

Record-Keeping and Audits

Keeping thorough records not only fulfills USPS requirements but also provides crucial proof of compliance. Without well-organized documentation, even a legitimate mailing could face delays, rejection, or penalties. It’s important to know what documents to keep, how long to keep them, and how to access them quickly when needed. Let’s break down the key documentation you’ll need to support your mailing claims.

Proof of Documentation and Compliance

Every mailing must include records that confirm its accuracy and back up any postage claims. For permit imprint mailings and those claiming discounts, electronic postage statements are required. These must be paired with USPS Qualification Reports, which detail everything from preparation and pricing to volume and postage data. For periodicals, you’ll need to keep entry listings that show the number of mailed copies and their price levels for at least two months after mailing. For large-volume mailings, retain full bundle details – including product or edition codes and pricing – for 90 days, and address any changes immediately.

If you’re a large-volume mailer, be ready to provide complete bundle details within three working days if the USPS requests them. Additionally, any corrections to a postage statement must be documented and updated right away, either by you or your mailing agent.

| Record Type | Minimum Retention Period | Response Time if Requested |

|---|---|---|

| Full bundle detail (large-volume jobs) | 90 days | 3 working days |

| Periodicals detailed entry listings | 2 months | – |

| Electronic postage statements | Accompanies each mailing | Immediate |

Table: USPS documentation requirements.

Once you’ve established proper record-keeping, it’s essential to conduct regular audits to ensure everything stays on track.

Internal Compliance Audits

In addition to meeting USPS documentation standards, routine audits are critical for maintaining compliance. A good rule of thumb is to conduct these audits quarterly, aligning with the 90-day retention requirement for large-volume mailings. These reviews should confirm that all necessary records are complete, properly formatted, and can be retrieved within the USPS’s required three-day window.

During audits, check the following:

- Address list hygiene: Ensure compliance with CASS certification and Move Update standards.

- USPS Qualification Reports: Verify they include essential details like the mailer’s name, mailing ID code, processing date, and mail class.

- Certifications: Confirm current PAVE or MAC certification for your mailing systems.

If your documentation doesn’t meet USPS requirements, a postmaster may request additional information. Failing to provide this could lead to rejected mailings, which can disrupt your schedule. To avoid setbacks, establish a reliable system for quick record retrieval and keep all campaigns running smoothly.

Working with a Mailing Service Partner

Ensuring compliance with direct mail regulations can be a daunting task, especially when navigating complex USPS rules and industry standards. This is where teaming up with a skilled mailing service provider can make all the difference. These experts take on the heavy lifting, streamlining compliance processes and reducing the chances of costly mistakes. From address validations to documentation, they can manage the intricate details, leaving you free to focus on other aspects of your campaign.

Certified mailing partners are well-versed in USPS requirements, handling tasks like sorting, preparing specialized containers, and completing postage statements with precision. This level of preparation helps avoid delays and eliminates the high costs of reworking non-compliant mailings. However, it’s important to note that, as the Federal Trade Commission emphasizes, "The law makes clear that even if you hire another company to handle your email marketing, you can’t contract away your legal responsibility to comply with the law". While the responsibility ultimately falls on you, working with a qualified partner can substantially lower your compliance risks.

Mailing and Fulfillment Services

Certified providers bring expertise in ensuring address accuracy, managing permits, and preparing mail to meet USPS presort standards. They maintain Full-Service Certification (FSC), ensuring all mail meets quality benchmarks and passes MERLIN (Mail Evaluation Readability Lookup Instrument) verification. Additionally, they utilize Intelligent Mail barcodes (IMb), which not only reduce postage costs but also enable precise tracking. If your campaign targets California residents, ensure your partner can handle CCPA/CPRA requirements, such as processing deletion requests and managing opt-out preferences.

Custom Printing and Post-Press Services

Compliance doesn’t stop at mailing preparation – it extends to the design and printing of your mailpieces. A reliable service provider will review designs against DMM physical standards before printing begins, helping to avoid costly reprints. This review includes checking dimensions, barcode placement, and ensuring all necessary elements are properly displayed.

For example, Miro Printing & Graphics Inc., based in Hackensack, NJ, offers a full range of printing and post-press services tailored to meet compliance needs. Their capabilities include digital, offset, and large-format printing, complemented by in-house bindery services like folding and die-cutting. For campaigns featuring Customized MarketMail (CMM) formats with unique shapes or special features, their specialized die-cutting and finishing services ensure your mailpieces meet USPS "Mailability" standards while standing out in the mailbox. They also provide design support to ensure your mailpieces meet all physical and disclosure requirements from the outset. Partnering with Miro Printing & Graphics Inc. ensures that every step – design, printing, and fulfillment – meets USPS compliance standards seamlessly.

Conclusion

Meeting direct mail compliance standards is not just a formality – it’s a necessity. Falling short of USPS regulations can result in undelivered mail, loss of automation discounts, or even accusations of mail fraud. The USPS Delivers guide emphasizes the risks clearly: "Mistakes in design can mean your mail doesn’t qualify for automation discounts – or in the worst case, prevent your pieces from going through the mail at all".

The compliance checklist addresses critical areas such as USPS standards, CASS-certified address validation, required disclaimers, privacy protocols, and design specifications to qualify for automation discounts. By adhering to these guidelines, you ensure your direct mail is handled correctly – from its design and address accuracy to its legal disclosures and required documentation. These steps not only guarantee timely delivery but also help you avoid unnecessary penalties or delays.

For businesses looking to streamline this process, certified mailing experts offer valuable assistance. For example, Miro Printing & Graphics Inc., based in Hackensack, NJ, provides comprehensive services to make compliance easier. Their team evaluates mailpiece designs to ensure they align with DMM physical standards before printing, oversees CASS-certified address validation, and manages mailing permits and documentation. With in-house bindery services and expertise in Customized MarketMail formats, they help ensure your campaigns meet USPS "mailability" standards and all other regulatory requirements.

FAQs

What are the main USPS requirements for direct mail compliance?

To make sure your direct mail meets USPS standards, pay attention to these important aspects:

- Addressing: Write addresses clearly and legibly, using the correct format to avoid delivery issues.

- Postage and Markings: Reserve enough space for postage stamps and any required USPS markings.

- Mailpiece Design: Stick to USPS rules for size, shape, and weight to keep your mail compliant.

- Automation Standards: Ensure your mail meets USPS automation readability standards for faster processing.

- Postage Payment: Apply the proper postage based on the mail type and class.

Following these steps helps ensure your mail gets delivered smoothly, without unnecessary delays or extra charges.

What steps can businesses take to protect personal data in direct mail campaigns?

To keep personal data safe during direct mail campaigns, businesses need to implement robust security measures. Start by assessing the personal information you collect – only keep what’s absolutely necessary. Protect this data using tools like encryption, secure storage systems, and strict access controls to prevent breaches or unauthorized access. When data is no longer needed, ensure it’s disposed of securely to avoid any chance of misuse.

Following U.S. regulations, such as USPS mailing standards, is another critical step to ensure data is managed securely and accurately. It’s also smart to have a response plan in place for potential security issues, which can help reduce risks if an incident occurs. By combining strong data practices with regulatory compliance, businesses can better protect personal information throughout their campaigns.

What are the key legal guidelines for truthful advertising in direct mail?

When creating direct mail advertising, it’s essential to follow legal guidelines for truthful marketing. Make sure every claim in your materials is accurate, honest, and backed by solid evidence. Avoid misleading statements or over-the-top promises that you can’t prove.

Your ads should also be straightforward and easy to understand. Clearly present terms and conditions without burying important details or leaving out key information. Misleading or omitting crucial facts can lead to serious legal trouble, so focus on being transparent and upfront in your messaging.

Related Blog Posts

- Post-Press Quality Control Checklist

- Ultimate Guide to USPS Bulk Mailing Discounts

- How to Ensure Compliance in Legal Printing

- How to Allocate Direct Mail Budgets for ROI

https://app.seobotai.com/banner/banner.js?id=69740e1d12006df3517955b3