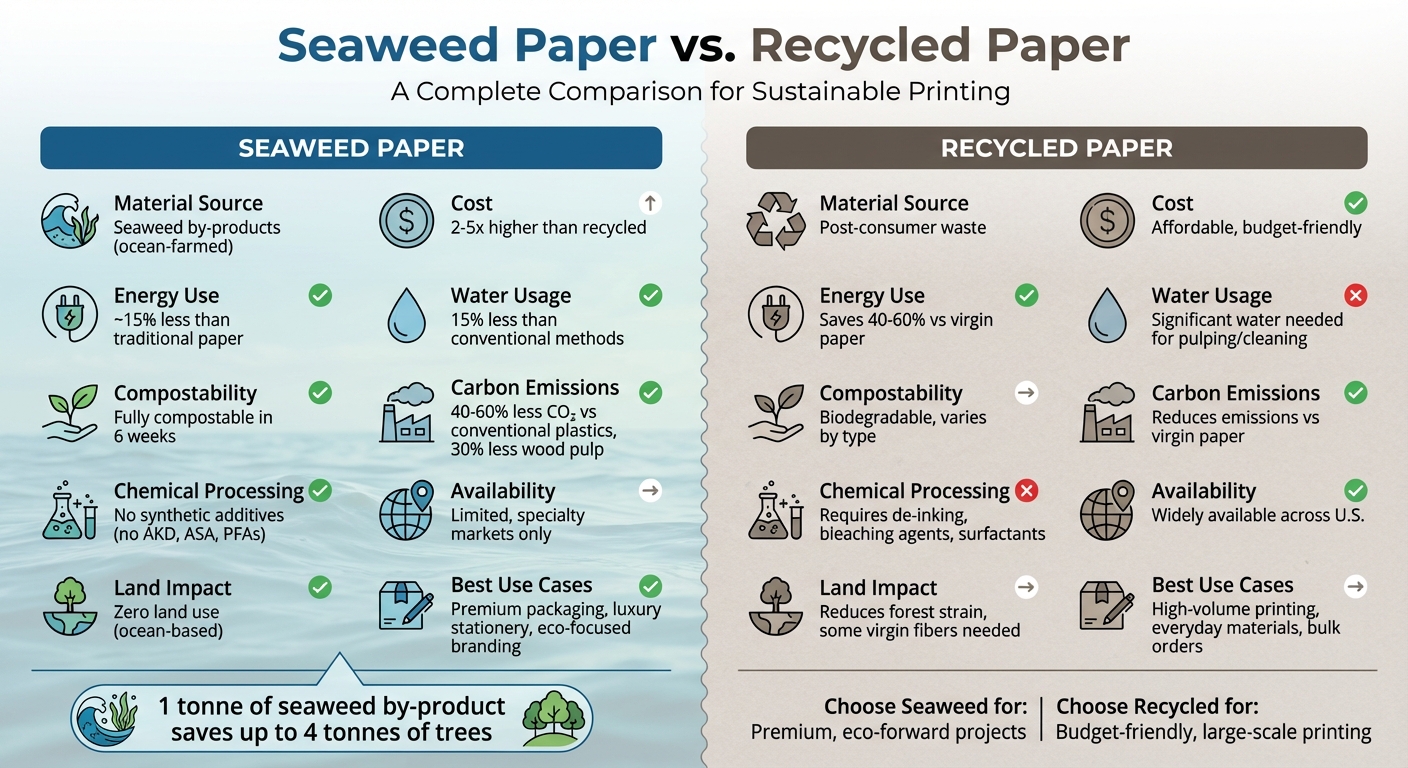

Seaweed paper and recycled paper both aim to reduce environmental impact, but they differ in production, cost, and usability. Seaweed paper, made with 30% seaweed fibers, saves resources like land and water, decomposes quickly, and avoids synthetic chemicals. However, it’s costly and limited in availability. Recycled paper, made from post-consumer waste, is affordable, widely available, and efficient for large-scale printing, though it requires chemicals for processing.

Key Points:

- Seaweed Paper: Uses ocean-farmed by-products, saves land and water, fully compostable, but 2–5x more expensive and less accessible.

- Recycled Paper: Reduces landfill waste, affordable, widely used, but involves chemicals and relies on some virgin fibers.

- Performance: Seaweed paper offers a textured, eco-conscious look but may not suit precise printing. Recycled paper is versatile and reliable for high-volume needs.

Quick Comparison:

| Feature | Seaweed Paper | Recycled Paper |

|---|---|---|

| Material Source | Seaweed by-products | Post-consumer waste |

| Cost | 2–5x higher | Affordable |

| Compostability | Fully compostable in 6 weeks | Biodegradable, varies by type |

| Energy Use | ~15% less than traditional paper | Saves 40–60% vs virgin paper |

| Availability | Limited, specialty markets | Widely available |

| Best Use | Premium packaging, stationery | High-volume, everyday printing |

Seaweed paper is ideal for premium, eco-focused projects, while recycled paper fits budget-friendly, large-scale printing. For a balanced approach, combine both based on your goals and budget.

Seaweed Paper vs Recycled Paper: Complete Environmental and Cost Comparison

Paper made from seaweed recycled from local beaches

How Each Paper Type Is Made

Seaweed paper combines seaweed by-products with wood pulp and recycled fibers, typically using around 30% seaweed content (as seen in Notpla Paper). On the other hand, recycled paper is crafted entirely from recovered post-consumer and post-industrial waste. The seaweed used in papermaking often comes from residual fibers left after hydrocolloid extraction, a process used in food, cosmetics, and pharmaceutical industries. Meanwhile, recycled paper relies on waste materials collected through curbside and commercial recycling programs. Depending on the grade, recycled paper can include anywhere from 10% to 100% post-consumer waste (PCW) fiber. These distinct methods highlight the unique origins of their materials.

Where the Materials Come From

Seaweed used for papermaking is sourced from farmed or harvested seaweed, cultivated primarily for other industries. After valuable compounds are extracted, the remaining fibrous by-products are repurposed for paper production. This approach minimizes waste, reduces strain on wild ecosystems, and avoids the need for additional land use. It’s a zero-waste system where every part of the resource is utilized. Recycled paper materials, on the other hand, are gathered through municipal recycling systems – like the paper you toss in your recycling bin at home or work. These materials are sorted at recovery facilities and then sent to paper mills for processing. The infrastructure for recycled paper is well-established across the United States, making it a widely available option.

Energy and Water Requirements

The way materials are sourced plays a big role in energy and water use during production. Seaweed paper production uses about 15% less energy than traditional papermaking, thanks to its reliance on seaweed and agricultural by-products. Seaweed farming doesn’t require land, freshwater, fertilizers, or pesticides, which also cuts water usage by about 15% compared to conventional methods. Recycled paper production, while also energy-efficient, can save up to 40–60% of the energy needed for virgin paper. However, seaweed paper has an advantage due to its renewable and non-land-based sourcing. Recycled paper processing, though effective, requires significant water for pulping and cleaning to remove inks and contaminants.

Chemicals Used in Production

The chemical processes for these two paper types differ significantly. Seaweed paper, such as Notpla‘s, is made without synthetic additives, including sizing agents like AKD or ASA, PFAs, or stabilizers. The natural qualities of seaweed fibers provide the necessary strength and printability, making the paper entirely biodegradable. Recycled paper, however, often involves chemicals for de-inking, bleaching, and strengthening the fibers. These include flotation agents, surfactants, and sometimes bleaching agents. Many mills now prioritize chlorine-free bleaching and closed-loop water systems to reduce environmental impact. Still, the chemical treatments required for recycled paper can slightly reduce its biodegradability compared to the natural, additive-free production of seaweed paper.

Environmental Effects of Each Paper

Carbon Emissions

Seaweed paper stands out for its lower carbon footprint compared to traditional papermaking. For instance, Notpla’s seaweed paperboard uses 30% less wood pulp than regular paper, cutting down emissions tied to forestry and pulp processing. Seaweed itself grows quickly in the ocean and doesn’t need land, freshwater, or fertilizers. Plus, its cultivation absorbs carbon and contributes to healthier coastal ecosystems . Life cycle studies suggest seaweed-based products can emit 40–60% less CO₂ compared to conventional plastics. On the other hand, recycled paper, especially when made entirely from post-consumer waste, helps cut emissions by reducing landfill contributions and the demand for fresh timber. However, the recycling process adds emissions from collecting, sorting, and re-pulping materials. Seaweed paper has a clear advantage here, thanks to its renewable marine source and carbon-absorbing properties. These emission differences also play a role in how the materials break down after use.

Decomposition and Marine Effects

When it comes to biodegradability, seaweed paper shines. Notpla’s seaweed-based paperboard is fully compostable within about six weeks under home composting conditions, as it doesn’t rely on synthetic additives like AKD, ASA, or PFAS. It naturally decomposes without leaving harmful residues behind. If seaweed paper ends up in the ocean, its organic ingredients break down much faster than synthetic-coated alternatives . Recycled paper is also biodegradable and recyclable, but its performance depends on the coatings, inks, and chemicals used during production. Papers treated with de-inking agents, bleaching chemicals, or plastic coatings may take longer to decompose and are often unsuitable for home composting. Additionally, both recycled and virgin papers disposed of in landfills can produce methane under anaerobic conditions. This underscores the importance of proper recycling and composting systems to manage their environmental impact.

Impact on Forests and Land

Looking beyond emissions and decomposition, the impact on land ecosystems is another key factor. Seaweed paper eliminates the need for land-based farming entirely, as seaweed grows in the ocean without requiring pesticides, irrigation, or land conversion . This ocean-based production method is particularly crucial given concerns about intensive forestry practices. Recycled paper reduces the strain on forests by using recovered fibers instead of relying solely on fresh timber. Depending on the type, recycled paper can include anywhere from 10% to 100% post-consumer material, with higher percentages offering greater environmental benefits. However, recycled paper still requires some land-based fibers, although it significantly lowers the need for virgin timber and diverts waste from landfills. Seaweed paper, by leveraging marine resources, further alleviates pressure on terrestrial ecosystems. Both materials play an important role in reducing deforestation and shrinking overall environmental footprints.

Price and Production Scale

Manufacturing Costs

Seaweed paper comes with a price tag that’s 2–5 times higher than recycled paper. This cost difference largely stems from the specialized processes required to combine seaweed by-products with recycled fibers, all while avoiding synthetic chemicals. While seaweed paper does save about 15% on energy and water usage, those savings don’t make up for the higher costs tied to production and scaling.

On the other hand, recycled paper benefits from a well-established and highly efficient supply chain. It uses post-consumer waste collected through municipal recycling programs, which keeps material costs low. Plus, streamlined processes – like de-inking, sorting, and pulping – further boost efficiency. This mature infrastructure makes recycled paper an economical choice, especially for large-scale commercial printing needs.

While sustainability fuels innovation, production costs and scalability are critical for market success. These cost differences highlight the challenges seaweed paper faces in competing with recycled paper.

Availability and Supply Chains

Economic factors also shape the accessibility of materials. Seaweed paper, for instance, is not widely available in commercial quantities. Companies like Notpla are focusing on niche uses, claiming to save up to 4 tons of trees for every ton of seaweed by-product used. However, its availability is still limited to specialty markets like packaging and labels. This is due to its reliance on marine farming by-products and the small number of processors equipped to handle these materials.

Recycled paper, by contrast, is readily accessible across the United States. A robust supply chain connects municipal recycling programs with mills capable of handling large volumes of post-consumer waste. This setup supports bulk orders with recycled content levels ranging from 10% to 100%. While some innovators are working to scale up seaweed paper production to achieve 100% wood-free alternatives, recycled paper continues to dominate the market due to its reliability and affordability.

sbb-itb-ce53437

Performance in Printing

Look and Feel

Seaweed paper stands out with its textured surface and natural flecks, giving it an earthy, organic appearance. This makes it a great fit for eco-conscious brands wanting to convey their commitment to sustainability right from the first interaction. On the other hand, recycled paper offers a more familiar and uniform look. Its finishes range from smooth, bright surfaces – perfect for corporate materials – to slightly rougher, grayish textures, depending on the level of post-consumer content and processing. This consistency makes recycled paper a reliable option, especially for projects where maintaining uniform color reproduction across large print runs is critical. Both materials pair their distinct aesthetics with essential performance features for printing and handling.

Strength and Durability

Seaweed paper uses 30% less wood pulp while still maintaining the strength needed for packaging applications. Its seaweed fibers add reinforcement, ensuring the material remains stiff and tear-resistant, making it suitable for products like boxes, sleeves, and envelopes. Recycled paper, benefiting from years of development, provides dependable tear strength and fold durability, making it ideal for items like manuals, pocket folders, and marketing materials. For projects requiring heavy handling or intricate folds, recycled paper’s established guidelines for scoring and creasing make it a safer, more predictable choice.

How Well They Print

Seaweed paper’s lack of synthetic additives makes it more absorbent, which results in softer details and muted colors compared to coated recycled stocks. Its off-white, speckled base can subtly shift printed colors, giving designs a natural, minimalist aesthetic – though it may not be the best choice for precise, color-critical images like photography. Recycled paper, available in both uncoated and coated varieties, offers more flexibility. Coated recycled paper delivers sharp images and vibrant colors, rivaling virgin coated stocks. For offset and digital printing, recycled paper is widely trusted, with well-documented profiles for ink behavior and toner adhesion. Seaweed paper, however, may require test runs to fine-tune press settings and drying times.

Both materials support sustainable printing practices and bring unique visual and technical benefits to the table. A full-service print shop like Miro Printing & Graphics Inc. in Hackensack, NJ, can help you determine which substrate aligns best with your project’s technical needs and design vision. These printing characteristics play a key role in selecting the right material for projects that demand specific standards.

When to Use Each Paper Type

Building on production insights and performance details, here’s how to make the most of each type of paper.

Best Uses for Seaweed Paper

Seaweed paper is perfect for specialty projects where a distinctive look and eco-conscious branding take precedence over cost or large-scale production. This paper is a standout choice for premium packaging – think natural beauty products, wellness brands, artisan foods, or eco-luxury goods. Its ocean-inspired, speckled texture tells a story of sustainability. For instance, using one tonne of seaweed by-product in Notpla Paper can save up to four tonnes of trees from being cut down.

In premium stationery, seaweed paper truly shines. Whether it’s wedding invitations, boutique business cards, artisanal letterhead, or notecards, its soft texture and natural fibers give an elevated, high-end feel. It’s best suited for low-to-medium volume projects where the higher cost is justified by the quality and uniqueness.

Best Uses for Recycled Paper

Recycled paper is the go-to choice for high-volume, budget-conscious printing. With its variety of weights and finishes and a well-established supply chain, it’s ideal for everyday needs like office printing, brochures, catalogs, manuals, direct mail, and standard business stationery. In U.S. commercial print shops, stocks containing 30–100% post-consumer recycled content are commonly used for large-scale jobs.

This paper type works especially well for projects with tight deadlines and broad distribution. Whether it’s training materials, forms, catalogs, or mass mailings, recycled paper delivers dependability. A smart approach is to save seaweed paper for standout pieces – like a hero package, VIP mailer, or limited-edition insert – while relying on recycled paper for the bulk of your materials. This strategy helps balance sustainability with budget considerations.

For a seamless integration of both paper types into a cohesive, eco-friendly print plan, full-service providers like Miro Printing & Graphics Inc. in Hackensack, NJ, can help bring your vision to life.

Which Paper Should You Choose?

Selecting the right paper depends on three main factors: environmental impact, budget, and the specific needs of your project.

Seaweed paper stands out for its minimal environmental footprint. It’s made from rapidly growing seaweed that doesn’t require land or freshwater to cultivate and breaks down completely in just six weeks under home composting conditions. However, this eco-friendly option comes at a premium – it costs 2–5 times more than traditional paper and is currently harder to source.

On the other hand, recycled paper is a budget-friendly alternative with an established supply chain across the U.S. Opting for recycled paper with 50–100% post-consumer waste content helps divert waste from landfills and lowers the need for virgin fibers, all at a fraction of the cost of seaweed paper. It’s also reliable for printing and works well for high-volume projects. That said, it doesn’t share seaweed paper’s zero-land-use benefits.

For those prioritizing bold sustainability and willing to invest more, seaweed paper is a fantastic option. Its naturally speckled texture and eco-conscious story make it perfect for branded packaging, luxury stationery, or limited-edition designs. Meanwhile, recycled paper is ideal for everyday printing needs like brochures, catalogs, direct mail, and office materials, offering both affordability and consistent quality.

Many businesses find value in using a mix of both. Seaweed paper can make a statement for high-impact, eco-forward pieces, while recycled paper handles cost-effective, large-scale projects. This balanced approach helps meet sustainability goals without straining budgets. If you’re unsure how to incorporate either type into your printing, full-service providers like Miro Printing & Graphics Inc. in Hackensack, NJ, can guide you in finding the right solution to align with your goals.

FAQs

How does seaweed paper compare to recycled paper in terms of environmental impact?

Seaweed paper offers a greener option compared to recycled paper, thanks to its environmentally friendly production process. It requires less water, produces fewer carbon emissions, and skips chemical bleaching altogether, resulting in a cleaner manufacturing approach.

What’s more, seaweed paper is biodegradable and made from renewable resources, tapping into marine materials that can also play a role in combating ocean plastic pollution. These qualities make it a compelling choice for anyone looking to adopt more eco-conscious printing practices.

Why is seaweed paper more expensive and harder to find than recycled paper?

Seaweed paper typically comes with a higher price tag and is harder to find compared to recycled paper, and there are a few reasons for this. For starters, the process of making seaweed paper is still in its early stages and isn’t as well-developed, which drives up production costs. On top of that, the raw material – seaweed – has a limited supply and must be harvested carefully to avoid overuse, adding another layer of expense.

On the other hand, recycled paper benefits from well-established production methods and a broad supply chain, making it both more affordable and easier to source. While seaweed paper does bring some distinct environmental perks, its higher cost and limited availability highlight the hurdles in expanding this newer material to a larger scale.

How does seaweed paper perform compared to recycled paper for large print runs?

Seaweed paper provides print quality comparable to recycled paper, especially for large-scale print jobs. That said, the final outcome can depend on the nature of the project and the printing technology employed.

For most high-volume printing tasks, both seaweed and recycled paper perform reliably. However, it’s wise to discuss your options with your printer to ensure the paper meets your project’s needs. Elements like texture, ink absorption, and finish might show subtle differences between the two materials.

Related Blog Posts

- Recycled vs. Virgin Paper: Cost Breakdown

- Pre vs Post-Consumer Recycled Paper: Key Differences

- Checklist for Choosing Recycled Paper for Printing

- Benefits of Using Bagasse Paper for Printing

https://app.seobotai.com/banner/banner.js?id=6941f6c089a9fb16dc707528