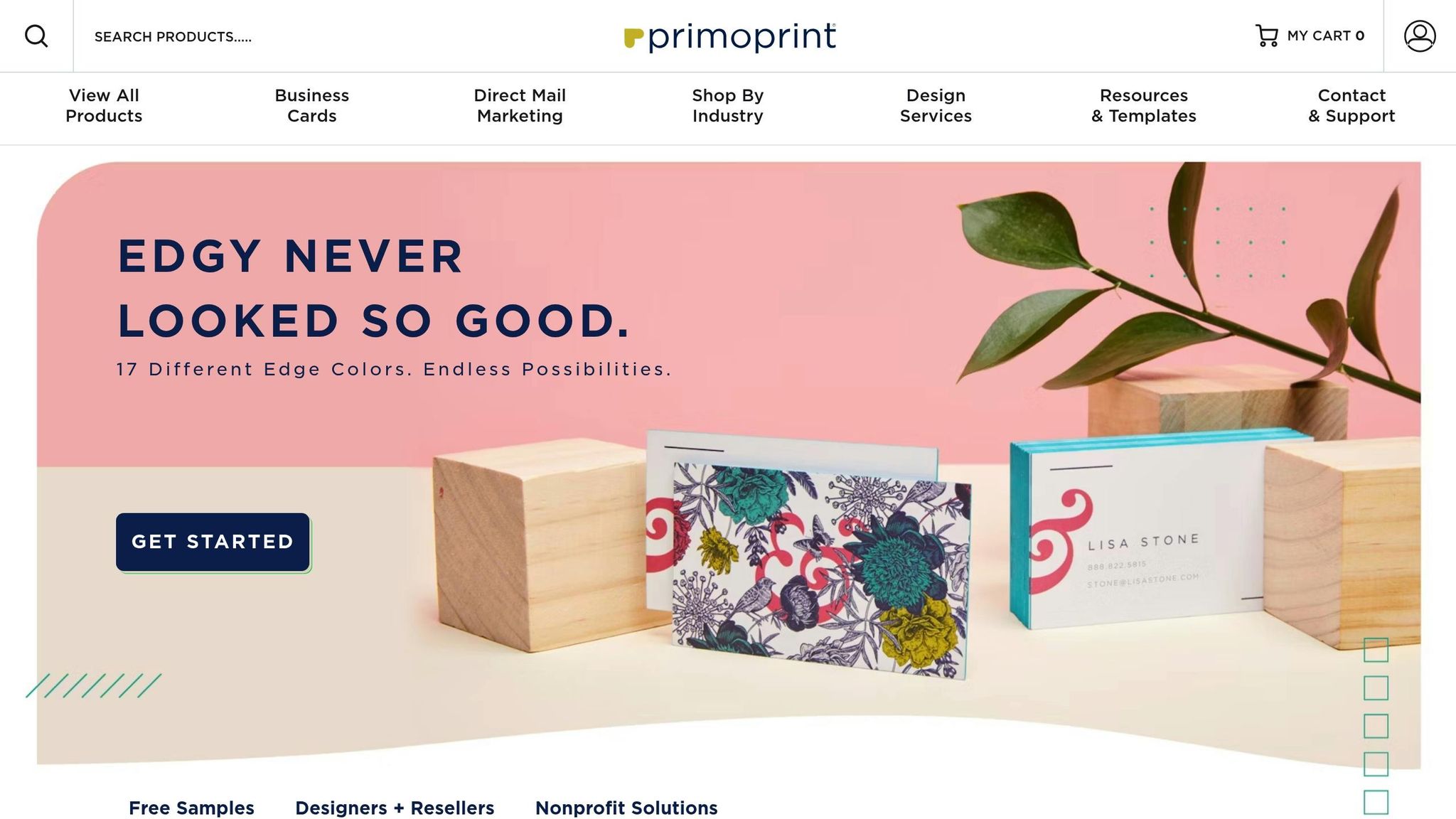

Foil stamping adds a polished, high-end look to printed materials like business cards, invitations, and packaging. However, the cost can vary based on factors like materials, design complexity, and production methods. Here’s what you need to know:

- Material Choices: Standard papers cost less, while textured or premium options increase expenses.

- Foil Types: Metallic foils are affordable, but specialty options like holographic foils are pricier.

- Design Complexity: Intricate designs require more labor and higher die setup costs.

- Production Volume: Larger orders reduce the per-unit cost by spreading fixed expenses.

Foil Stamping Methods:

- Hot Foil Stamping: Best for large runs but involves higher setup costs.

- Cold Foil Stamping: A flexible option for medium runs, using UV adhesives.

- Digital Foil: Cost-effective for small or custom projects, as it skips die creation.

To save money, focus on selective foiling, use standard materials, and plan bulk orders. Partnering with a skilled provider like Miro Printing & Graphics Inc. ensures quality results while keeping costs under control.

Best Cardstock for Hot Foil Stamping

Main Factors That Affect Foil Stamping Costs

Foil stamping adds a touch of sophistication and elegance to designs, but understanding what influences its cost is crucial for planning your project and managing your budget. Let’s break down the key elements that determine foil stamping expenses.

Material Selection

The type of paper you choose plays a big role in the cost. Standard paper options are typically more affordable, but if you opt for premium papers with unique textures or extra thickness, expect to pay more. Smooth, uncoated papers are ideal for foil stamping because they allow the foil to adhere more effectively. On the other hand, textured or coated papers may require additional preparation, which can increase costs.

Foil Type and Coverage Area

The type of foil you use can also impact your budget. Standard metallic foils are generally the most economical choice. However, specialty foils, like holographic or custom-colored options, come with a higher price tag. The size of the area being foiled matters, too – larger coverage areas require more material and labor. If you’re looking to save, consider using foil selectively to highlight key elements while keeping costs manageable.

Die Creation and Setup Costs

Creating the die is another factor to consider. The complexity of your design directly affects the cost of die production. Intricate designs take more time to create and set up, which increases labor costs. However, if you’re planning a larger print run, the cost per unit decreases as the setup costs are spread across more pieces. Keep in mind that precise setup and calibration are essential for achieving a flawless finish, and this attention to detail can add to the overall expense.

Foil Stamping Methods and Their Costs

The method you choose for foil stamping plays a big role in both the quality of the final product and the overall cost. Here’s a closer look at the key methods, how they work, and what impacts their cost.

Hot Foil Stamping

Hot foil stamping is a classic technique that uses heat and pressure to transfer metallic foil onto a surface. A heated metal die presses the foil onto the material, creating a permanent bond. While the upfront costs can be high due to the need for specialized equipment and custom metal dies, this method shines for larger production runs. The cost per unit decreases as the volume increases, making it a smart choice for detailed designs on items such as business cards, invitations, book covers, and packaging.

Cold Foil Stamping

Cold foil stamping skips the heat and instead relies on UV-curable adhesives to bond the foil to the material. Without the need for high temperatures, it reduces equipment and die costs. This method is also more versatile, allowing for textured or gradient effects and working well with heat-sensitive materials. While specialized adhesives and foils can add to the cost, cold foil stamping is a great middle-ground option for medium production runs where flexibility and efficiency are key.

Digital Foil Enhancement

Digital foil enhancement is a newer method that uses digital printing technology to apply foil, completely eliminating the need for custom dies. This makes it an affordable option for short runs, prototypes, or personalized projects. It offers impressive visual results and easily handles variable designs. However, opacity and durability can vary slightly compared to other methods. Still, for custom or limited-edition items, digital foil enhancement stands out as a convenient and cost-effective choice.

sbb-itb-ce53437

How to Reduce Foil Stamping Costs

Careful planning and smart design decisions can go a long way in cutting foil stamping costs without sacrificing the visual appeal of your project. By using foil strategically and making thoughtful choices, you can achieve a polished, professional look while staying within budget. Here are some practical ways to keep costs in check.

Focus on Selective Foiling

Selective foiling, often called spot foil stamping, is a great way to save money while maintaining a high-end appearance. Instead of applying foil to an entire surface, this method uses foil only on specific design elements like logos, names, or accents.

By concentrating foil on key areas, you reduce material usage and keep costs under control. For instance, highlighting a logo or a key piece of text with foil can add depth and make your design pop without overusing the material. This approach not only saves money but also enhances the overall design by drawing attention to the most important elements.

Interestingly, selective foiling often creates a more dynamic and engaging design than full foil coverage. It ensures that your focal points stand out while keeping expenses manageable.

Choose Standard Materials and Foils

The materials and foils you choose can significantly impact your budget. Sticking with standard paper stocks and commonly available foil colors is a straightforward way to keep costs down. While unique materials or custom foil colors might seem appealing, they often come at a premium price.

Classic foil shades like gold, silver, and copper are not only versatile but also cost-effective. Similarly, opting for standard paper weights and finishes simplifies production, which can lower overall expenses. Avoiding specialty papers or uncommon textures can help you achieve a polished look without overspending.

Plan for Bulk Orders

Ordering in bulk is another smart way to reduce foil stamping costs. Fixed expenses – like creating the die, setting up equipment, and preparation time – are spread across a larger number of items, which lowers the per-piece cost.

If possible, plan your foil stamping needs for multiple projects or timeframes to take advantage of better pricing tiers. Combining orders for seasonal campaigns or recurring events can help you avoid repeat setup charges and maximize savings. For businesses with consistent designs, bulk orders can be especially cost-effective, offering significant savings over time.

Working with Miro Printing & Graphics Inc.

Finding ways to save on costs while maintaining quality is much easier when you partner with a team that knows the ins and outs of both design and production. That’s where Miro Printing & Graphics Inc. steps in. Based in Hackensack, NJ, this full-service print shop combines expertise, top-tier equipment, and a wide range of services to deliver professional results while keeping your budget in check.

Foil Stamping Services

Miro Printing & Graphics Inc. has honed its craft in foil stamping, offering techniques that elevate the look and feel of printed materials. Using advanced equipment and high-quality materials, they ensure sharp, clean results that give your brand a polished, professional edge.

Their team is well-versed in the intricacies of various foil types and can help you choose the right materials to achieve your desired look without overspending. Whether you’re considering hot foil stamping for a classic touch or exploring digital foil enhancement for a modern twist, their technical expertise ensures that your project hits the mark in both design and cost-effectiveness. This seamless blend of knowledge and skill extends across all of Miro’s comprehensive service offerings.

Full-Service Benefits

Miro Printing & Graphics Inc. takes a full-service approach, simplifying the entire production process. With their in-house design team, you can collaborate directly with experts who understand the specific requirements of foil stamping from the outset. This approach often leads to smarter, more budget-friendly design decisions because production efficiency is factored in from the beginning.

Beyond foil stamping, Miro offers a wide array of services, including digital and offset printing, as well as post-press options like cutting, folding, and binding. By handling everything in one place, you save time and reduce costs since there’s no need to juggle multiple vendors.

Their in-house bindery is particularly helpful for complex projects. With everything managed under one roof, you avoid the delays and miscommunications that can crop up when coordinating with multiple providers. This streamlined process not only saves time but also helps keep your budget on track.

Getting Accurate Cost Estimates

Accurate cost estimates are key to managing your budget and making informed decisions. Miro Printing & Graphics Inc. provides detailed quotes tailored to your project’s specifics, ensuring transparency and clarity.

To get the most precise estimate, gather all project details before reaching out. This includes your preferred print format, quantity, dimensions, paper stock, and foil stamping requirements. If your project involves foil stamping, be sure to outline which areas will feature foil, your color preferences, and any unique design elements.

When submitting your request, include complete artwork and detailed specifications, such as foil placement, colors, and page count. For multi-page projects like catalogs or booklets, specifying the exact page count helps avoid delays in the quoting process.

If you’re unsure about any aspect of your project, Miro’s team is ready to assist. Their experience with foil stamping ensures they can guide you through the process, even if you’re unfamiliar with the technical details.

For added clarity, request itemized quotes that break down costs for each component of your project. This level of detail makes it easier to understand where your money is going and helps identify areas where adjustments can be made to better align with your budget. If anything in the quote seems unclear, don’t hesitate to ask for explanations to ensure every cost and service is fully understood.

Conclusion

Foil stamping costs become clearer when you understand the factors that influence them. Elements like material choices, foil types, and die costs all play a role in shaping the final expense. By recognizing how these pieces fit together, you can make informed decisions that balance aesthetics with your budget.

The method you choose also impacts both cost and appearance. Hot foil stamping offers a timeless, high-end finish but involves higher setup costs, making it ideal for larger projects. On the other hand, digital foil enhancement provides a more flexible option for smaller runs, as it doesn’t require custom dies. Each technique has its strengths, depending on your project’s needs and timeline.

Managing costs effectively often comes down to making smart choices. Opting for selective foiling, using standard materials, and planning in bulk can significantly lower per-unit costs without compromising the quality of your finished product. These strategies allow you to achieve a polished, premium look while staying within budget.

Partnering with a seasoned provider like Miro Printing & Graphics Inc. simplifies the process. Their full-service capabilities eliminate the need to juggle multiple vendors, and their in-house design team can enhance both the visual appeal and cost-efficiency of your project. With detailed, itemized quotes, you gain transparency into every cost component, helping you avoid surprises and make well-informed decisions. Their comprehensive approach ensures seamless integration of design and production, delivering consistent results from start to finish.

Investing in foil stamping is worthwhile. With careful planning and the right partner, you can achieve a professional and striking look that elevates your materials while keeping expenses under control. Whether it’s business cards, invitations, or marketing pieces, understanding these cost factors gives you the power to bring your vision to life without overspending.

FAQs

What’s the most cost-effective foil stamping method for my project based on size and design complexity?

Choosing the right foil stamping method for your project comes down to balancing cost, design complexity, and production size. Cold foil stamping is often the more budget-friendly option for larger production runs. It skips the need for heated dies and performs best with simpler, less intricate designs.

On the flip side, hot foil stamping shines when working on smaller projects or designs that demand precision and fine detail. Its tooling allows for a high level of intricacy, making it the go-to choice for more elaborate creations.

To keep costs down, stick to bold and straightforward designs. Intricate, multi-layered effects or detailed patterns usually require extra tooling, which can drive up expenses. By assessing your project’s specific requirements, you can choose the most suitable method without overspending.

How can I lower foil stamping costs while still achieving a high-quality design?

To keep foil stamping costs in check without compromising on quality, focus on applying foil to specific design elements like logos or small accents instead of larger areas. This targeted approach reduces material usage and helps trim expenses.

Simplifying your design can also go a long way. Opt for bold, straightforward shapes and clean lines, as these are easier and more cost-effective to work with during the hot foil stamping process. Pairing this with high-quality foils and collaborating with skilled printers can significantly improve the final outcome while minimizing waste.

Finally, pay close attention to the temperature and pressure settings during the stamping process. Fine-tuning these parameters can help avoid errors and reduce material loss, ensuring your designs maintain their quality without stretching your budget.

How do materials and foil choices affect the look and cost of a foil stamping project?

The materials and foils you select can make a big difference in both the look and cost of your foil stamping project. Specialty foils – like metallic, holographic, or matte finishes – add a polished, attention-grabbing touch that can take your design to the next level. Pairing these with premium papers can further enhance the quality and feel of the finished piece.

That said, these upgrades come with a price. Specialty foils and high-end materials are often more expensive, with foil rolls typically costing between $30 and $50 each. More intricate designs, such as full-coverage or holographic effects, may also require additional time and resources, which can drive up production costs. Striking the right balance between your design goals and your budget is essential for achieving the results you want.

Related Blog Posts

- Ultimate Guide to Post-Press Finishing

- Foil Stamping vs Metallic Ink: Key Differences

- How Foil Stamping Works: Step-by-Step Guide

- Foil Stamping Techniques for Cardstock Printing

https://app.seobotai.com/banner/banner.js?id=68d5dc31e3dd4bddfa53e71b