3D printing is transforming the commercial printing industry. Instead of competing with offset and digital printing, it complements them, creating new opportunities for businesses. Over the past three years, its adoption has surged, enabling print shops to handle custom projects, prototypes, and dimensional objects with ease. This shift is reshaping how businesses approach packaging, marketing materials, and production workflows.

Key Takeaways:

- 3D Printing Integration: Print shops are combining 3D printing with offset and digital methods to offer hybrid solutions like custom packaging and tactile marketing materials.

- Benefits: Reduced waste, faster prototyping, and increased flexibility for small runs.

- Challenges: Material compatibility, slower production speeds, and the need for cross-trained staff.

- Future Trends: Automation, multi-material systems, and AI-driven quality control are making 3D printing more accessible and efficient.

Why it matters: Businesses that integrate 3D printing can offer more customized, high-value services, improving client retention and expanding their market reach.

How 3D Printing is Changing Businesses: From Our HQ to Real-World Applications

Current 3D Printing Trends in Commercial Printing

The commercial printing industry is undergoing three key transformations that are redefining how print shops operate and deliver value to their customers. These shifts go beyond mere technological updates – they are creating fresh business opportunities and altering traditional workflows.

3D Printing Becomes Standard Equipment

In the United States, 3D printers have become indispensable tools for commercial printing businesses, much like digital printing once transitioned from a niche option to a standard practice. These machines fill service gaps by enabling the production of prototypes, custom fixtures, and dimensional marketing materials – things traditional printing methods can’t achieve.

Many print shops start small, using desktop 3D printers to produce prototypes and gauge market interest. As demand grows, they often invest in industrial-grade 3D printers, scaling their capabilities without risking significant upfront costs.

New software solutions are also bridging the gap between 3D and traditional printing systems, streamlining job management and reducing the learning curve for operators. This integration is paving the way for a seamless blend of 3D printing with more conventional methods.

Combined Printing Technologies

The combination of 3D printing with offset or digital printing is unlocking new possibilities for hybrid products that neither technology could produce alone. For instance, custom packaging can feature printed graphics alongside 3D-printed structural elements, while promotional materials can combine vivid visuals with tactile, raised details that stand out.

Advancements in software and standardized file formats have largely resolved the technical hurdles of merging these technologies. Print shops can now switch seamlessly between production methods within a single project, ensuring each component is crafted using the most effective technique.

Quality control processes have also evolved to address mixed media workflows, with checks for color consistency, fit, and durability. Beyond product innovation, these combined methods are offering notable advantages in reducing environmental impact.

Environmental Benefits

3D printing’s additive nature significantly reduces material waste, unlike traditional subtractive manufacturing methods. Its on-demand production model eliminates the need for excessive inventory, while the use of biodegradable and recycled materials further lowers its environmental footprint. Additionally, energy-efficient machines and localized production for smaller print runs help cut carbon emissions, making 3D printing a greener choice for commercial printing businesses.

How 3D Printing Works with Existing Printing Methods

Blending 3D printing with commercial printing processes enhances traditional offset and digital workflows without replacing them. This combination allows businesses to take on projects that might otherwise be too complex or expensive using conventional methods alone. The integration focuses on two key areas: improving traditional prints and addressing challenges in hybrid workflows.

Supporting Offset and Digital Printing

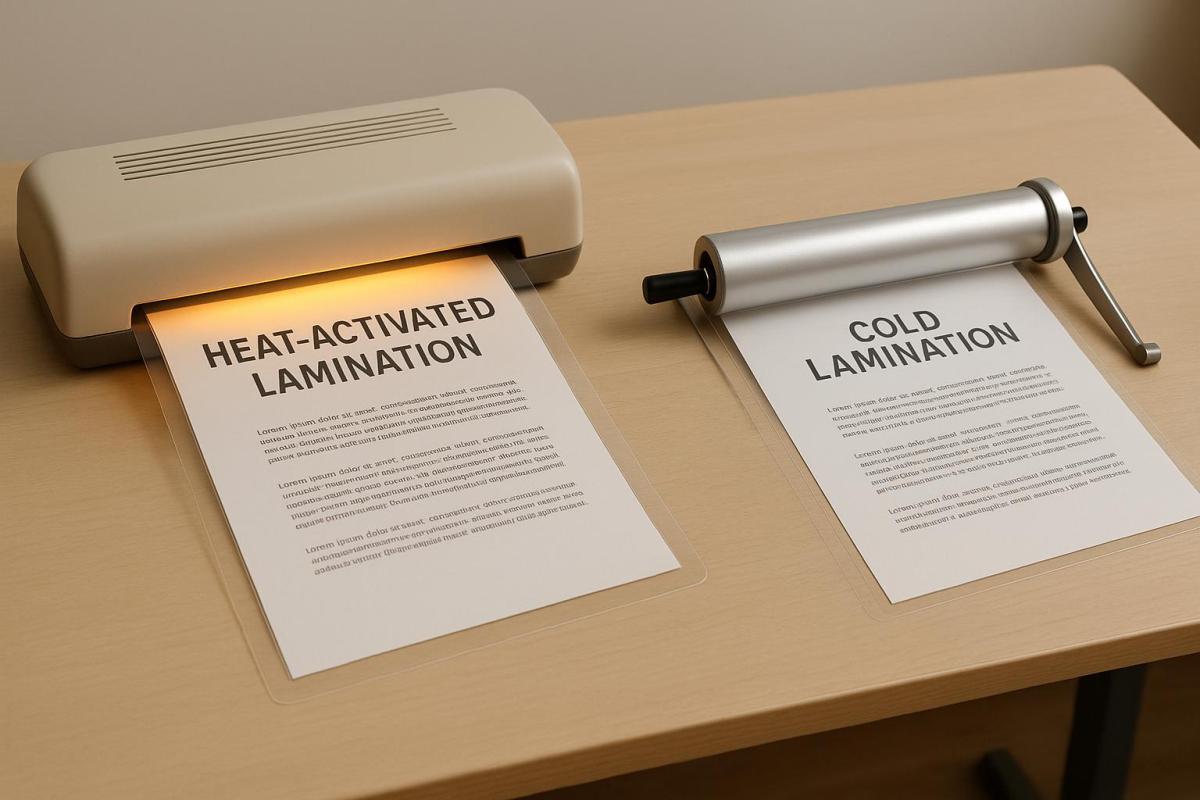

3D printing takes flat printed materials to the next level by adding depth and dimension. While traditional offset printing delivers sharp graphics and text on materials like paper and cardboard, 3D printing introduces structural elements, textures, and functional components that elevate the final product.

Take custom packaging, for example. A cosmetics company might use offset printing to create vibrant labels and eye-catching packaging designs, then incorporate 3D-printed elements – like custom-shaped caps or textured surfaces – to enhance both functionality and shelf appeal.

Marketing materials also benefit from this synergy. Trade show displays can pair digitally printed visuals with 3D-printed structural components, making them easier to assemble and transport. Prototyping is another area where the integration shines. Designers can now combine printed graphics with 3D elements, allowing clients to visualize and test designs before committing to full-scale production.

Workflow Problems and Solutions

Despite its advantages, combining these methods introduces some unique challenges. One major issue is material compatibility. Adhesives, inks, and substrates designed for conventional printing don’t always work well with 3D-printed materials. To address this, many print shops have implemented standardized material testing. These tests help determine the best combinations of inks, adhesives, and 3D printing filaments, ensuring smoother project setups and consistent results.

Another challenge is coordinating equipment. Offset presses can churn out thousands of pieces per hour, but 3D printers often take hours to produce even a small batch. Initially, this timing mismatch caused delays and scheduling headaches. To solve this, production schedules have been restructured so that 3D printing runs simultaneously with traditional printing. Digital inventory systems now synchronize the production of printed and 3D components for seamless assembly. In some cases, shops have added multiple smaller 3D printers to distribute workloads and minimize delays.

Quality control has also evolved to meet the demands of hybrid products. Traditional quality checks focus on aspects like color accuracy and print defects, but 3D printing requires additional checks for dimensional accuracy, surface finish, and mechanical strength. Many shops have set up hybrid quality control stations equipped with tools for both color measurement and precision testing.

Training staff has been another critical step. Cross-training programs now teach operators the ins and outs of both traditional and 3D printing processes. This helps teams identify potential issues early and make informed decisions about production timelines and sequencing. Investing in training ensures high-quality results while meeting tight deadlines.

File management systems have adapted to handle the complexities of hybrid projects. Modern workflow software now integrates 2D designs with 3D models, automatically generating production schedules that maximize equipment efficiency. These systems also track material use across both printing methods, improving cost estimates and inventory management.

Real Applications and Business Impact

3D printing has become a game-changer for commercial printing operations, not just as a technical innovation but as a proven way to boost revenue. Local print service providers, like Miro Printing & Graphics Inc., are increasingly adopting this technology to streamline processes and offer creative solutions.

Custom Packaging Solutions

One of the standout uses of 3D printing is in packaging. This technology has made it easier – and faster – for brands to create prototypes, helping them test packaging ideas before investing in expensive tooling or committing to large-scale production.

For example, cosmetics companies are using 3D printing to add unique textures, custom-shaped closures, and intricate details to their packaging. These features not only enhance the sensory appeal of their products but also allow for cost-effective production of limited editions or seasonal campaigns.

The speed of prototyping is another major advantage. What used to take weeks can now be done in days, enabling designers to present physical prototypes during meetings. This accelerates the approval process and reduces the number of revisions needed.

Beyond aesthetics, 3D printing supports structural innovations in packaging. It allows for the creation of custom inserts, complex internal supports, and protective elements tailored to the exact dimensions of a product. This is especially useful for industries like electronics, where durable and precise packaging is critical. These solutions not only protect the product but also help reduce material waste.

Marketing and Promotional Items

When it comes to marketing, 3D printing opens up exciting possibilities. Dimensional promotional items – like custom giveaways at trade shows – grab attention without requiring high minimum orders. This flexibility allows businesses to create more targeted campaigns that resonate with specific audiences.

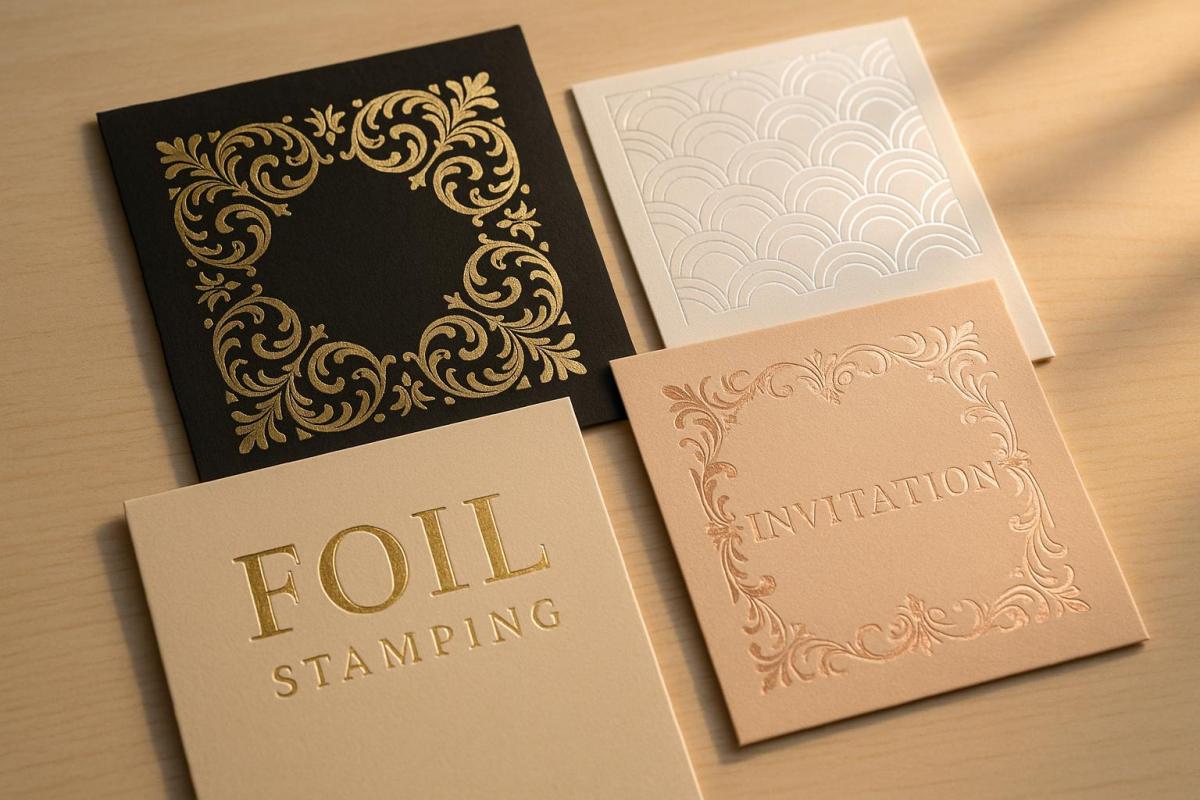

Interactive marketing pieces are another area where 3D printing shines. Business cards with 3D elements, dimensional direct mail pieces, and tactile product samples stand out from the crowd and often spark conversations. These unique pieces can generate buzz on social media and through word-of-mouth, giving brands an edge in competitive markets.

In B2B environments, 3D-printed models and product demonstrations make complex ideas easier to grasp. For instance, architectural firms and product designers are using 3D-printed prototypes to deliver presentations that leave a lasting impression.

But 3D printing isn’t just about wowing customers – it also has practical benefits behind the scenes.

Production Support Tools

On the production floor, 3D printing is transforming workflows by enabling the creation of custom tools. Whether it’s jigs, fixtures, cutting guides, or folding tools, these personalized solutions improve precision, reduce waste, and save time on repetitive tasks.

It’s also a game-changer for equipment maintenance. Instead of waiting for replacement parts or paying for costly service calls, print shops can produce custom components, protective covers, or operational aids in-house. This reduces downtime and cuts maintenance costs, helping businesses get more life out of their existing machinery.

Material handling is another area where 3D printing proves its worth. Custom trays, sorting devices, and transport fixtures simplify processes and reduce the risk of damage during handling. While these might seem like small improvements, they add up to significant gains in overall productivity.

sbb-itb-ce53437

3D Printing vs. Standard Printing Methods

Choosing between 3D printing and traditional methods like offset or digital printing requires a closer look at how they differ. Each has its strengths, depending on the needs of a project.

The biggest difference lies in cost and setup. Traditional offset printing involves a hefty upfront investment, with time-consuming processes like creating plates and setting up machines before production even begins. However, once set up, it can churn out thousands of units per hour efficiently. On the other hand, 3D printing skips the extensive setup, making it more accessible for smaller runs, but the per-unit cost tends to be higher.

Speed is another key factor. 3D printing shines in rapid prototyping, while traditional printing dominates when it comes to high-volume production. That said, advancements in 3D printing are closing the gap. For example, the SUP3R system recently demonstrated the ability to print 12 samples in just 15 minutes – cutting production time in half compared to conventional setups.

For larger orders, traditional offset printing becomes more economical once production surpasses 500 units. This makes it the go-to choice for large-scale commercial jobs.

Side-by-Side Comparison

| Factor | 3D Printing | Traditional Methods (Offset/Digital) |

|---|---|---|

| Setup Time | Quick (minutes to hours) | Longer (days to weeks for tooling) |

| Per-Unit Cost | Higher, relatively steady across volumes | Decreases significantly with larger orders |

| Customization | Highly flexible designs | Limited by fixed tooling requirements |

| Production Speed | Best for small runs; slower for mass production | Extremely fast for large volumes |

| Material Options | Limited but expanding | Wide variety of substrates, including specialty materials |

| Quality Consistency | Can vary based on machine settings | Very consistent once calibrated |

| Minimum Order | Cost-effective for single units or small batches | Economical only at higher volumes |

| Design Changes | Instant updates without retooling | Requires new setup, adding time and cost |

This comparison highlights how 3D printing is ideal for custom, small-scale projects, while traditional methods excel in large-scale, standardized production.

Material variety is another area where traditional printing has the edge. It offers a broad selection, from different paper weights to specialty materials like foils and plastics. While 3D printing materials are expanding quickly, they still lag in some specialized applications.

A hybrid approach is becoming more common as businesses realize they don’t have to stick with just one method. For example, 3D printing might be used for intricate custom components, while traditional printing handles the high-volume, standardized parts. This blend allows companies to leverage the strengths of both technologies.

Automation also plays a role. Traditional printing has long benefited from mature systems, while 3D printing is catching up with AI-driven optimizations and 24/7 operation through printing farms. These advancements are helping to reduce the speed gap, though traditional methods still lead in large-scale efficiency.

Ultimately, the choice depends on the project. 3D printing is perfect for prototypes, custom packaging inserts, and promotional items with intricate details in small runs. Traditional methods remain unbeatable for high-volume jobs, standard packaging, and projects requiring specific materials or finishes.

The landscape is evolving, though. New technologies like Carbon’s DLS, HP’s Multi Jet Fusion, and Desktop Metal’s Production System are reshaping large-scale 3D printing. These innovations may soon bring the best of both worlds, blending the flexibility of 3D printing with the efficiency of traditional methods.

What’s Next for 3D Printing in Commercial Printing

The commercial printing industry is on the brink of transformation as 3D printing technology becomes more advanced. Efforts in research and development are now centered on merging 3D printing with traditional printing methods. Investments in automation and new materials are driving this change, with the goal of making 3D printing a standard option alongside conventional techniques. This shift is fueled by improvements in technology and the growing demand for faster, more customizable production options.

Automation and Digital Workflows

Automation is playing a huge role in shaping the future of commercial printing. Smart workflow systems now automatically assign tasks to 3D printers, digital presses, or offset equipment based on the job’s complexity, size, and deadlines. This ensures efficiency and better resource allocation.

Unmanned, 24/7 operations are becoming a reality. Automated material handling systems allow printing facilities to run continuously, which is especially crucial for time-sensitive projects where traditional setups might cause delays.

AI-powered quality control is another game-changer. These systems monitor both 3D printing and conventional processes in real time, predicting potential issues and making adjustments to maintain consistent quality while reducing waste.

Digital file preparation has also evolved. Modern software can now analyze incoming jobs and suggest the best combination of printing methods. For instance, a packaging project might use offset printing for the base design while relying on 3D printing for custom inserts.

Real-time inventory management systems are streamlining operations further by tracking material usage across different printing technologies. This helps optimize ordering and reduces downtime, which is especially important for 3D printing materials that often have unique storage needs compared to traditional substrates.

Together, these advancements in automation and workflows are laying the groundwork for exciting developments in materials and processes.

New Materials and Process Development

The range of materials compatible with 3D printing is expanding rapidly. Multi-material printing systems are making it possible to work with materials commonly used in commercial printing, like specialty papers and flexible substrates. This allows for seamless integration of 3D printed elements with traditional printed components.

Conductive inks and smart materials are unlocking new possibilities, such as creating interactive packaging and promotional items that go far beyond what standard printing can achieve.

There’s also a push toward more sustainable options. Biodegradable and recycled materials are being developed to match the durability and appearance of traditional materials while offering the design flexibility that 3D printing provides. This is becoming increasingly important as environmental concerns grow.

Efforts to improve speed and efficiency are ongoing. Emerging technologies aim to rival or even surpass the production speeds of traditional printing, particularly for short-run jobs where setup times have historically given conventional methods an edge.

Meanwhile, cost reductions in both materials and equipment are making 3D printing more accessible for commercial applications. Lower costs are helping to expand its use in areas where it was previously considered too expensive.

Another exciting innovation is the development of hybrid printing heads. These systems can switch between different material types in a single job, streamlining processes that combine traditional and 3D printed elements.

Lastly, scalability improvements are addressing one of the biggest hurdles for 3D printing. New systems designed specifically for commercial use can handle larger volumes without losing the customization benefits that make 3D printing so appealing. These solutions are being integrated directly into existing workflows, making them more practical for everyday use.

Companies like Miro Printing & Graphics Inc. in Hackensack, NJ are well-positioned to take advantage of these advancements. By embracing automation and new materials, they can meet changing market demands and provide more tailored printing solutions. These innovations are solidifying 3D printing as a key component of the commercial printing industry.

Conclusion

The commercial printing industry stands at a transformative moment as 3D printing evolves from being a niche technology to a crucial addition to traditional methods. Studies highlight that 3D printing shines brightest when paired with offset and digital printing techniques. This combination offers businesses a chance to cater to the rising demand for personalized, on-demand products while tapping into specialized market segments.

To stay competitive in this shifting landscape, companies must rethink their strategies. By doing so, they can seize new market opportunities while mitigating risks tied to these industry changes.

As highlighted throughout, 3D printing is no longer optional – it’s a key player in the commercial printing toolkit. Blending traditional and 3D printing methods fosters both innovation and efficiency. Companies like Miro Printing & Graphics Inc. showcase how this integrated approach can position businesses for long-term success in an increasingly competitive market.

FAQs

How does 3D printing enhance traditional printing methods in commercial use?

3D printing takes traditional printing methods to the next level by making it possible to create detailed molds, prototypes, and casting patterns. These additions not only streamline manufacturing processes but also allow for greater flexibility in design. It’s particularly useful for producing intricate, high-quality components that would otherwise be challenging or expensive to make using conventional methods.

This technology has unlocked new opportunities for businesses like Miro Printing & Graphics Inc. By blending the accuracy of traditional printing with the capabilities of 3D printing, they can now offer a broader range of services. Whether it’s custom-designed projects or advanced manufacturing solutions, this combination helps them cater to a wide variety of client demands.

What challenges do print shops face when incorporating 3D printing into their current workflows?

Integrating 3D printing into existing workflows isn’t always straightforward for print shops. One of the main hurdles is technical compatibility. Combining traditional methods with advanced 3D printing often demands specialized software and equipment, which can complicate the process.

Another challenge lies in maintaining consistent quality. Achieving uniform results becomes tricky, particularly when working with intricate or highly detailed designs that push the limits of the technology.

On top of that, material limitations and restrictions on print sizes can pose obstacles for certain projects. These constraints require print shops to carefully adjust and refine their workflows to ensure everything runs smoothly and efficiently while meeting client needs.

How does 3D printing promote sustainability in the commercial printing industry?

3D printing is transforming the commercial printing industry by drastically cutting down on material waste – by as much as 90% compared to conventional methods. Even better, it enables the use of recyclable and environmentally friendly materials, contributing to a circular economy where resources are reused rather than discarded.

This technology also simplifies production processes, which means less energy is consumed and fewer emissions are generated. By reducing the reliance on heavy machining and long-distance transportation, 3D printing helps shrink the overall carbon footprint, making it a more environmentally conscious option for modern manufacturing.

Related posts

- How Automation Improves Print Turnaround Times

- How to Choose Cost-Effective Printing Materials

- Top 7 Typography Trends in Commercial Printing 2025

- Latest Trends in Automated Die-Cut Packaging Production

https://app.seobotai.com/banner/banner.js?id=689d138d8204a37d5f991083