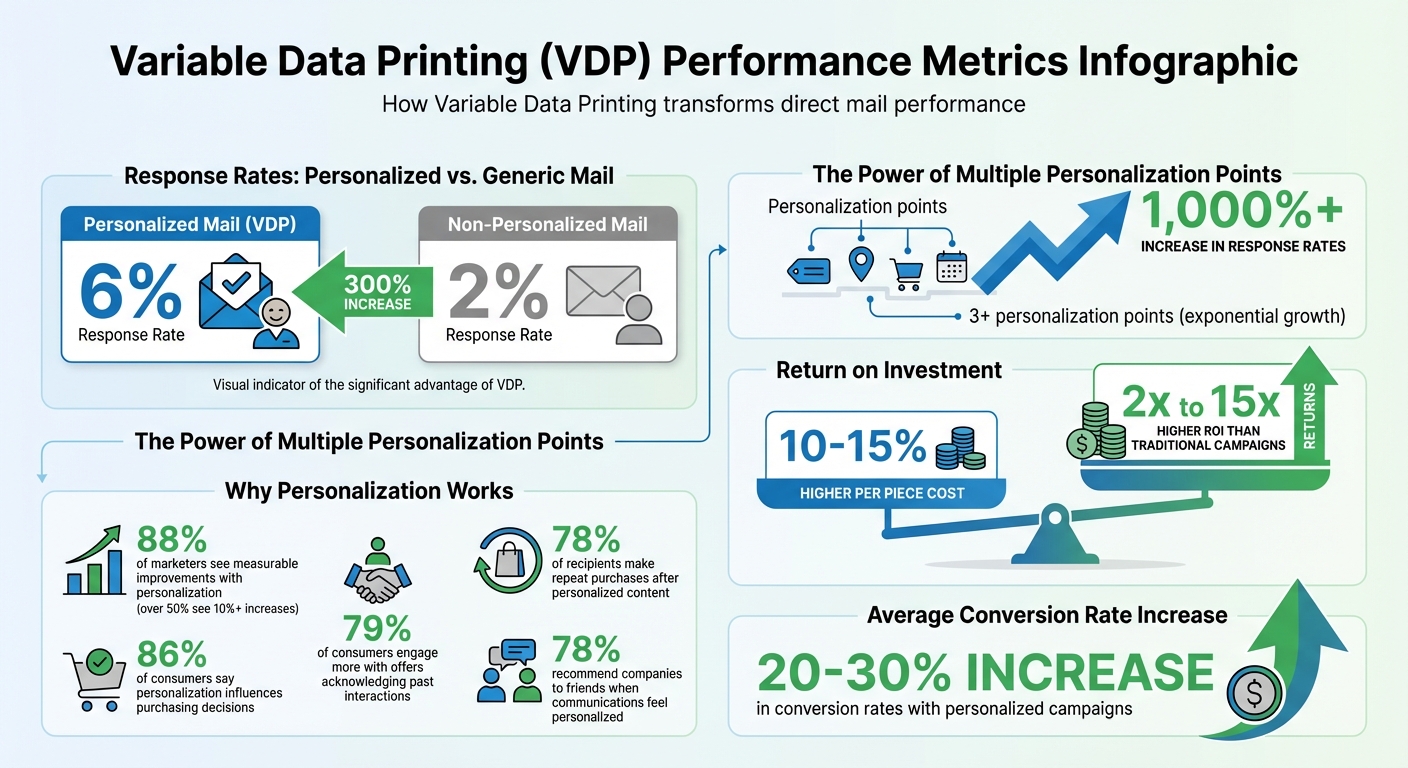

Variable Data Printing (VDP) transforms direct mail by allowing businesses to create personalized messages for each recipient in a single print run. Unlike generic mail, which offers the same message to everyone, VDP uses customer data – like names, purchase history, and preferences – to customize text, images, and offers. This approach boosts engagement, with personalized mail seeing response rates of 6% compared to 2% for non-personalized campaigns. It also improves ROI, with returns 2x to 15x higher than static mailings.

Key Points:

- What It Does: Customizes mail pieces using recipient-specific data.

- How It Works: Combines a fixed design template with variable elements (e.g., names, offers) pulled from a database.

- Benefits: Increases response rates, improves customer loyalty, and reduces waste by targeting the right audience.

- Tracking Tools: Uses personalized URLs (pURLs), QR codes, and coupon codes to monitor responses and refine future campaigns.

- Cost Efficiency: While slightly more expensive per piece, VDP reduces overall waste and maximizes ROI.

VDP is a powerful tool for creating direct mail that feels personal, relevant, and effective in driving customer action.

Variable Data Printing Statistics: Response Rates and ROI Comparison

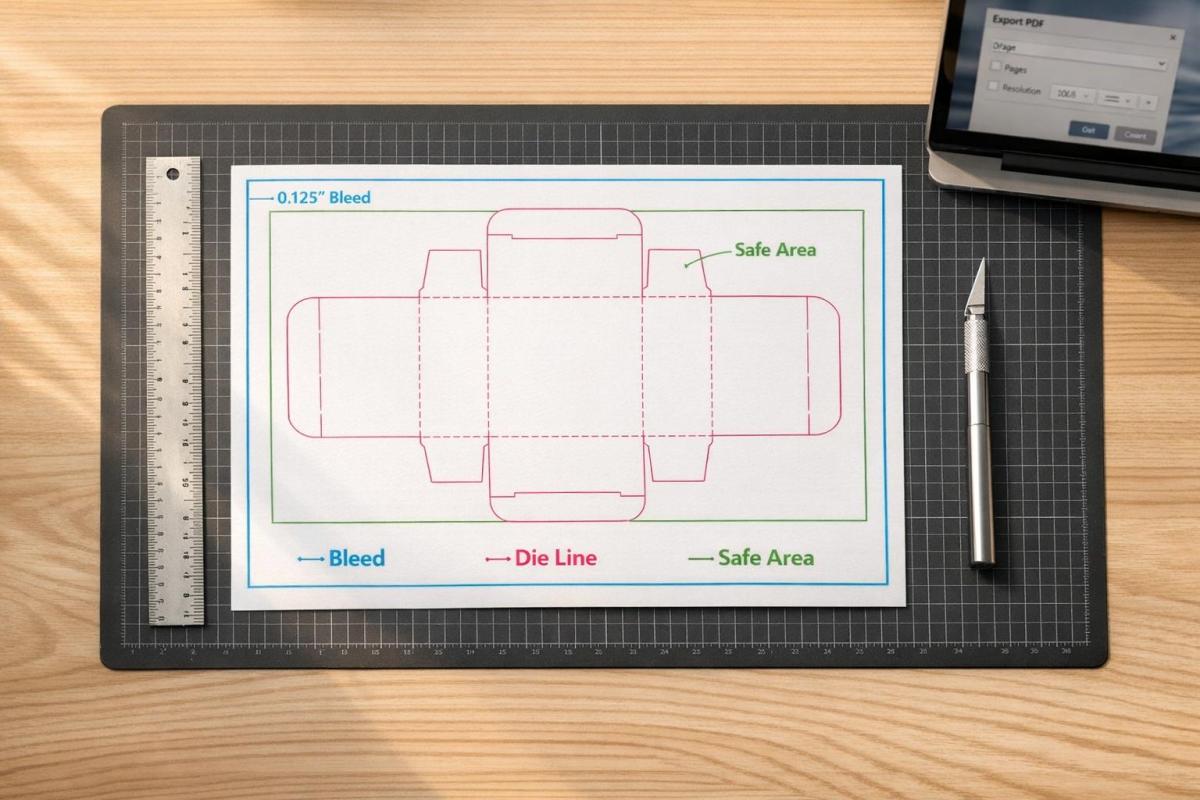

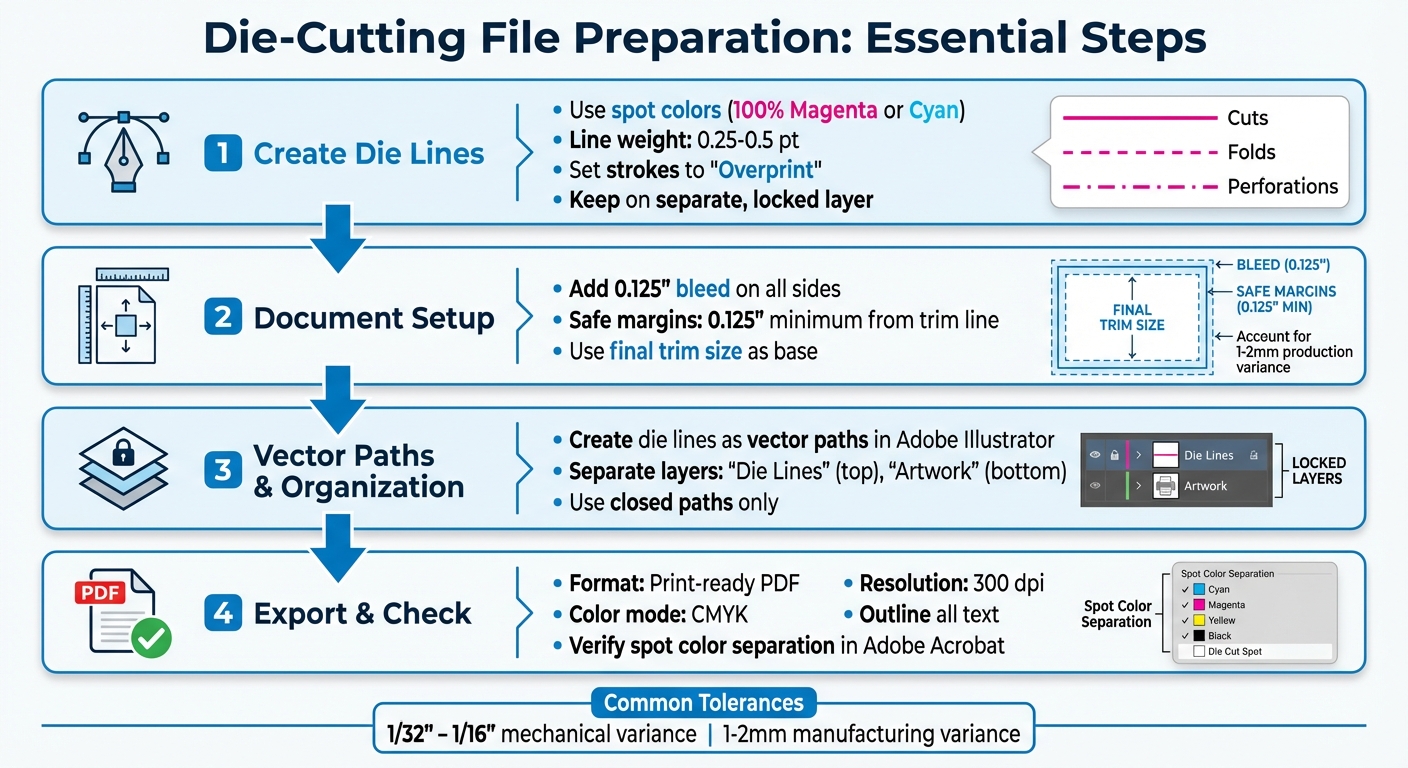

Variable Data Printing: study and print file preparation

How Variable Data Printing Works

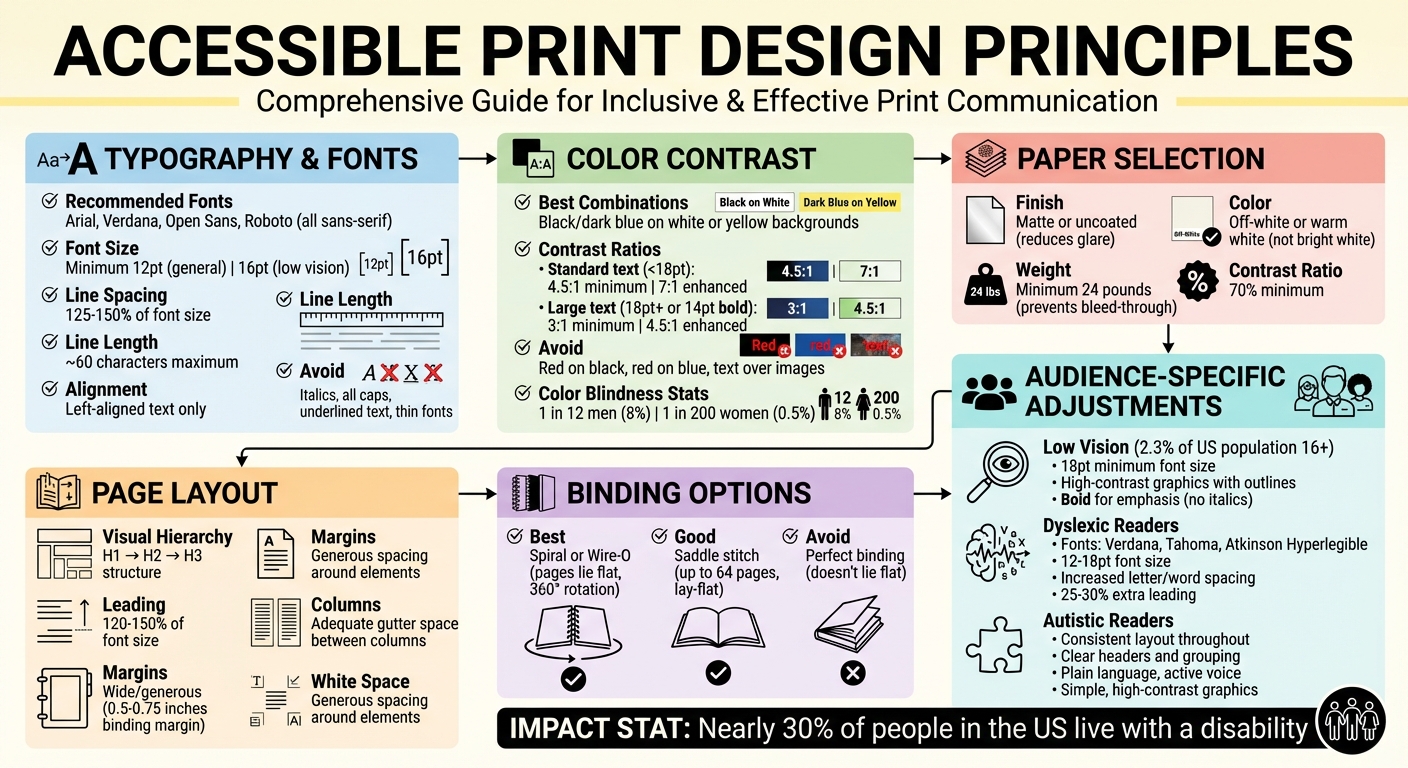

Variable data printing (VDP) merges a fixed design template with personalized customer data to create unique mail pieces in a single print run. The static template includes consistent elements like your logo, brand colors, and background graphics. Meanwhile, the variable elements – such as recipient names, product suggestions, or tailored images – are layered in based on information from your database. This approach ensures every mail piece feels personal and aligns with the recipient’s details.

The process relies on data mapping, which links fields in your database to placeholders in the design. VDP software acts as the connector, matching specific columns in your data file (usually a CSV or Excel sheet) to placeholders in the template. For example, a column labeled "First Name" in the spreadsheet connects to a text box marked "[First Name]" in the design. The software then automatically populates each piece with the correct name – "Sarah" for one recipient, "Michael" for another.

Unlike traditional offset printing, which uses fixed physical plates, VDP employs digital printers that dynamically pull data. This allows the printer to adjust each piece on the fly without pausing production, making large-scale, one-to-one personalization seamless.

Using Customer Data for Personalization

Your customer database is the backbone of VDP. Companies typically gather this data from various sources, including CRM systems, purchase histories, loyalty programs, and demographic profiles. The key to success lies in organizing this data into clean, structured columns – such as first name, last name, address, purchase history, or preferred product categories.

"Be sure to provide your spreadsheet data as a CSV file. If uploading a mailing list, be sure to separate all of your data into unique columns (first name, last name, address line 1, etc.) or follow our template!"

– Anna Coons, Print Services Manager, Smartpress

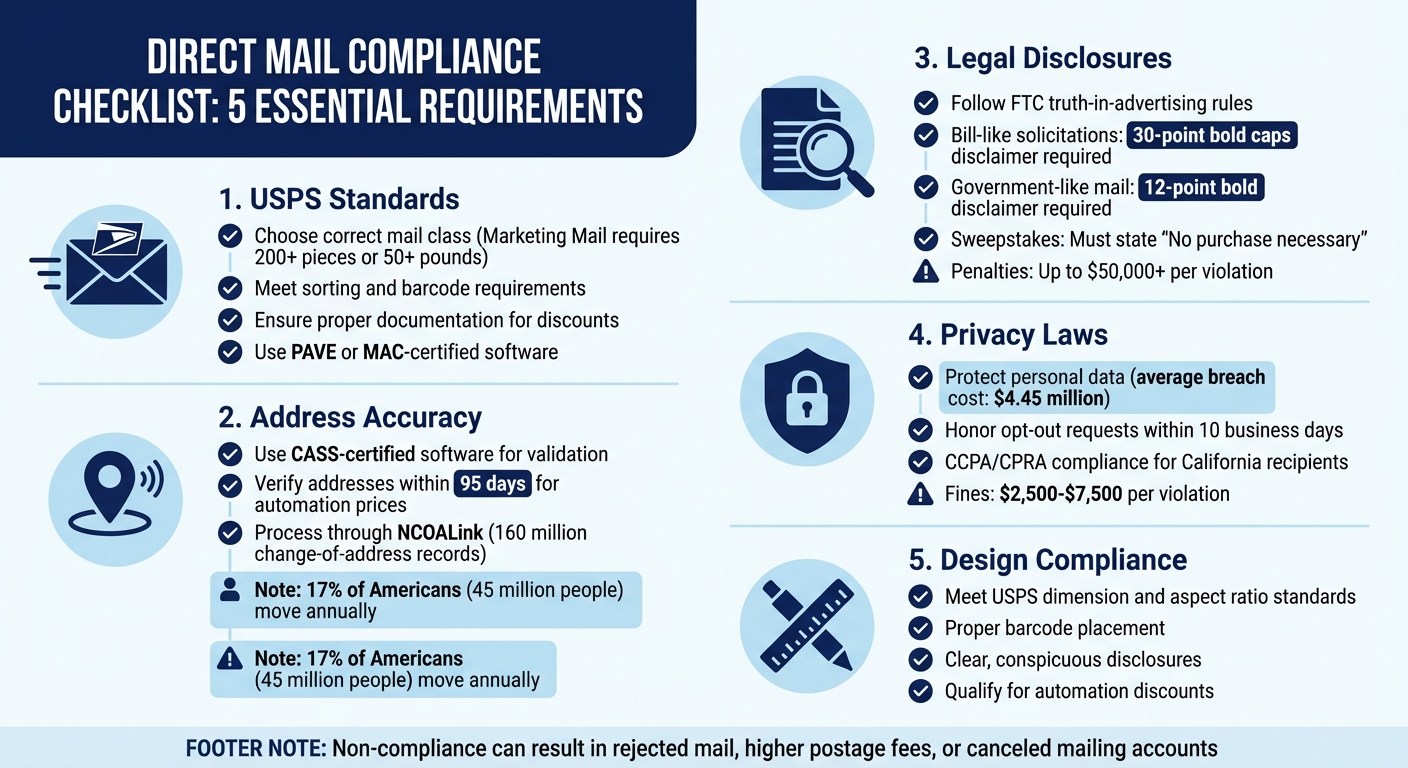

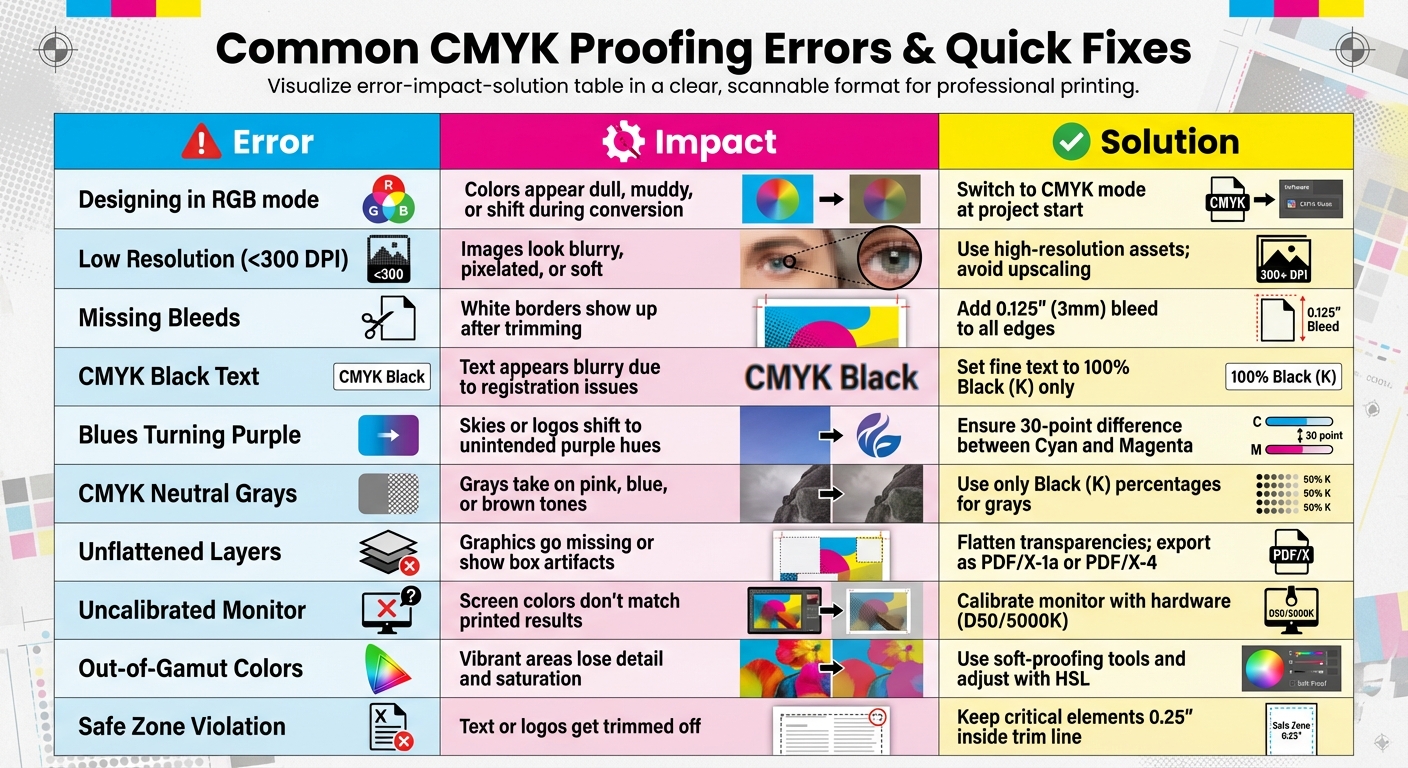

Before printing, it’s essential to clean your data. This means removing duplicates, verifying addresses with tools like CASS or NCOA, and fixing errors in one go. Sending mail to an outdated address or addressing someone incorrectly doesn’t just waste resources – it can damage trust. Once your list is verified, the VDP software maps each field to its corresponding placeholder in the design template, ensuring precise personalization for every piece. This well-organized data not only ensures accuracy but also enables dynamic customization of both text and visuals.

Customizing Text, Graphics, and Images

VDP isn’t limited to adding names – it allows you to tailor text, graphics, and even images to resonate with individual recipients. For example, headlines, offers, and calls-to-action can be adjusted for different customer segments. A loyal customer might see, "Thanks for 5 years with us!" while a new prospect might get, "Welcome! Enjoy 20% off your first order."

Graphics and images can also be personalized. A sporting goods retailer could showcase hiking boots to customers who’ve previously purchased outdoor gear, while marathon runners might see ads for running shoes. Some campaigns even include personalized maps, highlighting the fastest route from the recipient’s home to the nearest store.

Advanced VDP systems take this further by using barcodes to synchronize multiple personalized items – like a custom letter, a matching coupon, and a tailored brochure – into one cohesive mailing package. When designing, it’s crucial to account for text length variations to avoid layout issues and maintain a polished presentation.

Benefits of Personalization in Direct Mail

Personalized direct mail consistently outshines generic campaigns. By using Variable Data Printing (VDP) to customize content for individual recipients, you create a tangible, personal connection that digital channels often struggle to replicate. When mail includes someone’s name, reflects their purchase history, or highlights products they genuinely care about, it grabs attention, gets read, and prompts action. These stronger engagement metrics pave the way for increased loyalty and deeper connections with your audience.

Improving Engagement and Response Rates

Personalized direct mail achieves impressive results. With VDP, response rates climb to 6%, compared to just 2% for non-personalized mail – a 300% increase. Add three or more personalization points, and response rates can soar by over 1,000%. Recipients are far more likely to engage when the content feels tailored to them.

Take this example: a homeowners insurance campaign sent postcards featuring recipients’ names, addresses, specific home data, an image of their home, and a personalized insurance quote. These five VDP elements worked together to transform what might have been ignored as junk mail into something that demanded attention.

But the impact doesn’t stop at opening the envelope. 88% of U.S. marketers reported measurable improvements with personalization, with over half seeing increases above 10%. Additionally, 86% of consumers say personalized marketing influences their purchasing decisions. One outdoor retailer demonstrated this perfectly by sending hiking-related mail to a customer who had purchased hiking gear just once, even though their primary interest was cycling. This thoughtful use of VDP responded to evolving customer interests in real time.

"One-size-fits-all messaging is so irrelevant these days. You have to figure out how to adjust your content to match the needs of the customer." – Vanecia Carr, Director of Customer and Brand Marketing, Domtar

The numbers back this up: ROI from VDP campaigns ranges from 2x to 15x higher than traditional campaigns, even though these campaigns typically cost 10% to 15% more upfront. That initial expense is quickly offset by higher conversion rates and larger average purchases.

Building Customer Loyalty and Trust

The benefits of personalization extend far beyond immediate responses. By using VDP to reflect a customer’s history with your brand, you show them they’re more than just another entry in your database. 79% of consumers say they’re more likely to engage with offers that acknowledge past interactions, and 78% of recipients of personalized content are more likely to make repeat purchases.

For example, Suffolk Law School revamped its reunion campaigns by incorporating individual reunion years and donation histories. This turned generic fundraising efforts into meaningful, personal invitations.

Personalization also fosters trust and advocacy. 78% of customers are more likely to recommend a company to friends and family when communications feel personalized. This word-of-mouth effect means your investment in VDP can lead to referrals you didn’t even ask for.

Physical direct mail creates a lasting impression, offering a human touch that stands out in today’s digital-first world. When you include elements like personalized thank-you notes, service reminders tied to past behavior, or detailed maps to nearby store locations, you position your brand as a helpful partner – not just another advertiser.

"The personalized mail campaign connects with your consumer on a human-to-human level and creates an authentic long-term relationship built on familiarity, value, and trust." – Mailing.com

However, personalization must feel thoughtful, not invasive. Accurate data is critical – sending mail to outdated addresses or using incorrect names can harm trust rather than build it. When done right, personalized direct mail shows customers you recognize, remember, and value them, building stronger relationships one piece of mail at a time.

sbb-itb-ce53437

Cost Efficiency and Reduced Waste

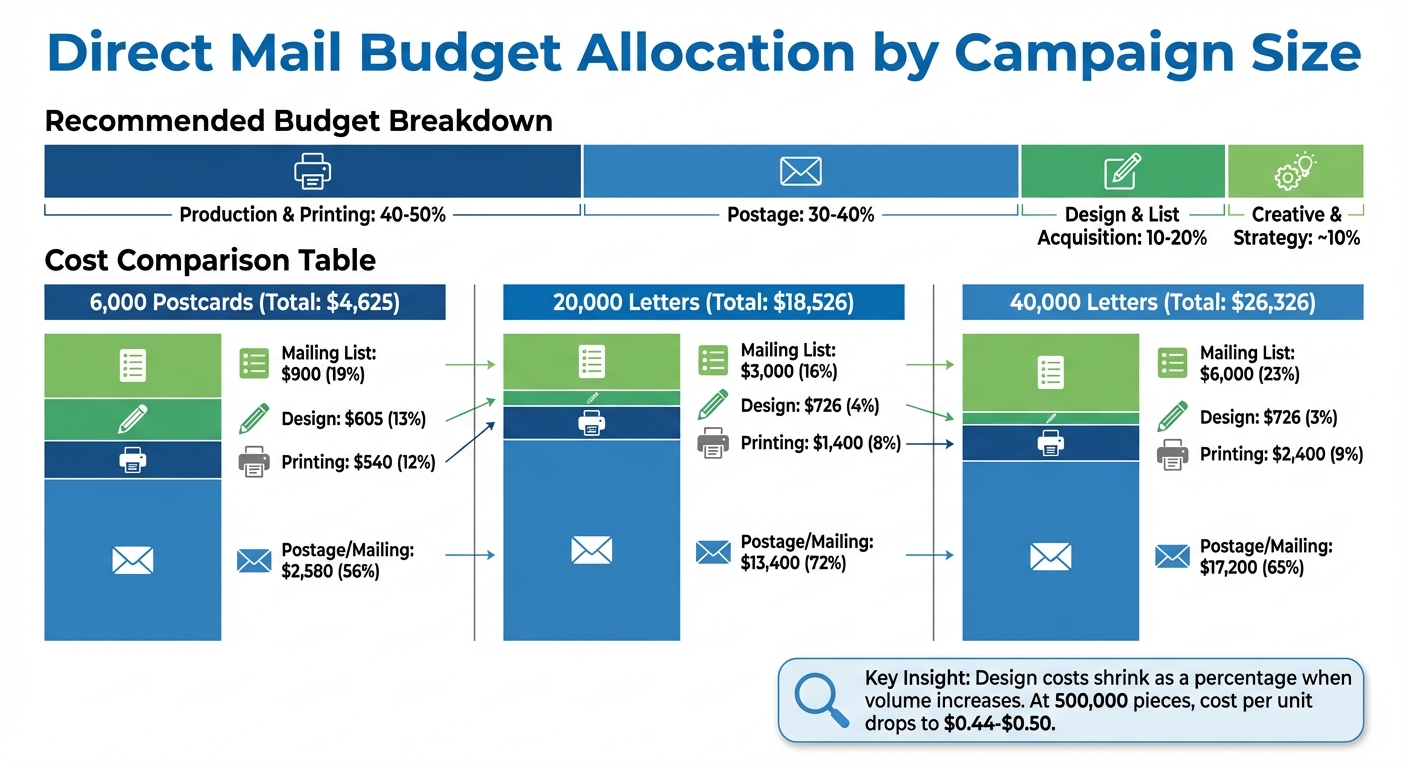

Although variable data printing (VDP) campaigns can cost 10% to 15% more per piece compared to static printing, they often deliver better financial results by cutting down on waste and honing in on the right audience. Traditional offset printing comes with high setup costs – like plate creation and bulk orders – which often leave businesses stuck with outdated, unused materials. VDP, on the other hand, uses digital technology to skip plate fees entirely, letting you print only what’s needed and avoid extra inventory or storage expenses. This makes it a smart choice for targeted campaigns.

Cutting Printing Costs with Targeted Campaigns

Targeted mailing is a game-changer for reducing costs. By focusing solely on qualified leads, you can significantly lower production and postage expenses. In fact, VDP can provide 2 to 15 times the return on investment (ROI) compared to traditional static campaigns, mainly because it avoids wasting resources on mail that recipients might toss out immediately.

"The smaller-volume mail campaign increases the ROI due to lower postage and printing costs." – Mailing.com

Instead of fixating on upfront printing costs, it’s better to measure success by cost per conversion. A well-targeted campaign connects with those most likely to respond, minimizing overall spending on production, paper, and postage.

Reducing Paper Waste

VDP also supports sustainability by shifting from bulk printing to on-demand production. Beyond saving money, this approach significantly reduces paper waste. Traditional printing methods often result in large amounts of excess inventory, creating thousands of tons of paper waste every month. On-demand printing ensures you only produce what’s necessary, which is not only efficient but also environmentally responsible.

Another benefit? It encourages better data hygiene. Regularly cleaning up your mailing lists to remove outdated or incorrect addresses helps reduce waste even further. Plus, you can experiment with different designs or offers using small print runs before committing your full budget. This way, you can test your messaging without the risk of printing large quantities of materials that might not perform as expected.

This combination of precision targeting and on-demand printing doesn’t just cut waste – it also helps you get the most out of your marketing dollars.

Miro Printing & Graphics Inc. (https://bergencountyprinters.com) specializes in advanced digital and variable data printing, making it easier to create personalized direct mail campaigns that are both budget-friendly and environmentally conscious.

Tracking and Improving Campaign Performance

Variable Data Printing (VDP) makes it easy to track every direct mail response with precision. Unlike traditional campaigns where you’re left wondering who responded, VDP uses personalized tools to monitor individual interactions. Tools like Personalized URLs (pURLs), unique QR codes, and custom coupon codes act as digital fingerprints. Each tool connects a specific recipient to their response, offering clear insights into campaign performance.

These tracking capabilities go hand-in-hand with the personalization benefits discussed earlier. Personalized campaigns typically boast a 6% response rate, compared to just 2% for non-personalized mail. With such detailed data collection, you can build comprehensive profiles of your audience’s interests and behaviors. This data can then be analyzed using web analytics to fine-tune future campaigns.

Using Personalized Tracking Tools

These personalized tracking tools connect individual responses to tailored content, making it easier to see what works. For example:

- Personalized URLs (pURLs): Each recipient gets a unique web address, allowing you to track when they visit and how they interact with your site.

- Unique QR Codes: Perfect for mobile users, these scannable codes let you track engagement from those who prefer scanning over typing.

- Custom Coupon Codes: These track redemptions and tie specific sales back to individual mail pieces.

| Tracking Tool | Functionality | Primary Metric Tracked |

|---|---|---|

| PURL (Personalized URL) | Unique web address for each recipient | Web visits and on-site behavior |

| Unique QR Codes | Scannable codes unique to individuals | Mobile engagement and conversions |

| Custom Coupon Codes | Personalized discount codes | Redemption rates and sales tracking |

VDP also simplifies A/B testing. You can experiment with different headlines, images, or offers within the same print run to see which elements drive the most engagement. Start small by allocating about 10% of your direct mail budget to testing VDP variables before scaling up. This low-risk approach helps you learn what works without overspending.

Analyzing Campaign Metrics

Once you’ve collected data through these tools, analyzing the right metrics is key to improving your campaign. Instead of just counting how many pieces you mailed, focus on response rates, conversion rates, and return on investment (ROI). VDP can deliver anywhere from two to 15 times the ROI of a traditional static campaign. Key performance indicators (KPIs) to measure include:

- Response Rate: Responses ÷ Mailpieces Sent

- Conversion Rate: Orders ÷ Responses

- ROI: (Net Profit ÷ Total Investment) × 100

On average, personalized campaigns see a 20% to 30% increase in conversion rates. Proper tracking ensures you know whether you’re meeting these benchmarks.

"It’s not the response rate alone that determines the success of a campaign but its return on investment (ROI)." – Mailing.com

Integrating your direct mail platform with a CRM can provide even deeper insights. By syncing with your CRM, you can track not just initial purchases but also the long-term customer lifetime value (CLV) of respondents. This data helps you identify which audience segments are the most profitable, guiding your strategy for future campaigns.

Conclusion

Variable Data Printing (VDP) shifts direct mail from impersonal mass marketing to tailored, one-on-one communication with your audience. By personalizing elements like names, offers, images, and messages based on individual preferences and purchase history, VDP creates mail pieces that truly resonate. Personalized campaigns achieve a 6% response rate, compared to just 2% for generic mail, and they can increase conversion rates by 20% to 30% on average.

VDP doesn’t just enhance engagement – it also eliminates costly plate fees through digital production and focuses on likely responders. The results? Dramatically higher response rates, with some campaigns seeing 300% to 600% increases. While the per-piece cost may be slightly higher, the improved response rates more than make up for it, delivering a stronger return on investment (ROI).

"VDP flips traditional marketing on its head by centering product and service offers… around the individual needs and wants of each customer." – Mailing.com

Another standout feature of VDP is its ability to track and measure performance with precision. Tools like personalized URLs, unique QR codes, and custom coupon codes allow you to see exactly who responds, giving you a clear picture of your ROI. This data becomes a valuable resource for refining future campaigns and strengthening customer relationships over time.

FAQs

How does Variable Data Printing boost ROI for direct mail campaigns?

Variable Data Printing (VDP) helps boost ROI by enabling businesses to craft personalized direct mail that connects directly with each recipient. By customizing elements like names, images, offers, and messages, VDP creates a more engaging experience, leading to higher response rates and stronger customer relationships.

Unlike generic, mass-produced mail, personalized campaigns stand out, capturing attention and encouraging action. This focused strategy not only improves conversion rates but also ensures your marketing budget delivers measurable returns.

What customer data is needed to create personalized direct mail with Variable Data Printing?

To create personalized direct mail using Variable Data Printing, you’ll need to gather specific customer information, such as:

- Name and address: This ensures accurate delivery while adding a personal touch.

- Demographics: Details like age, gender, or income help fine-tune your message.

- Purchase history: Past orders provide clues for crafting relevant offers.

- Preferences and behaviors: Knowing what customers enjoy or how they interact with your brand makes customization more impactful.

With this data in hand, you can design direct mail campaigns that feel tailored to each recipient, boosting engagement and delivering better results.

How can businesses ensure their data is accurate for Variable Data Printing campaigns?

To achieve accurate results in Variable Data Printing (VDP) campaigns, it’s essential to start with a meticulous review of your customer data. This means checking every detail – names, addresses, and other personalized information – for errors. Duplicates should be eliminated, formatting issues corrected, and all data cross-referenced with reliable sources to catch mistakes before they become costly.

Another key step is running test prints or sample proofs. These allow you to spot and fix any discrepancies in the personalized elements before rolling out the full campaign. On top of that, using secure methods for data transfer, like encrypted files, helps safeguard the integrity and confidentiality of your information. Regular database updates and audits also play a big role in keeping your data accurate over time, ensuring your campaigns remain effective and build trust with your audience.

Related Blog Posts

- 8 Metrics to Track Direct Mail Success

- 10 Budget Mistakes in Direct Mail Campaigns

- Common Print Marketing Mistakes That Waste Money

- How to Allocate Direct Mail Budgets for ROI

https://app.seobotai.com/banner/banner.js?id=6976cc9b12006df3517d3ad1