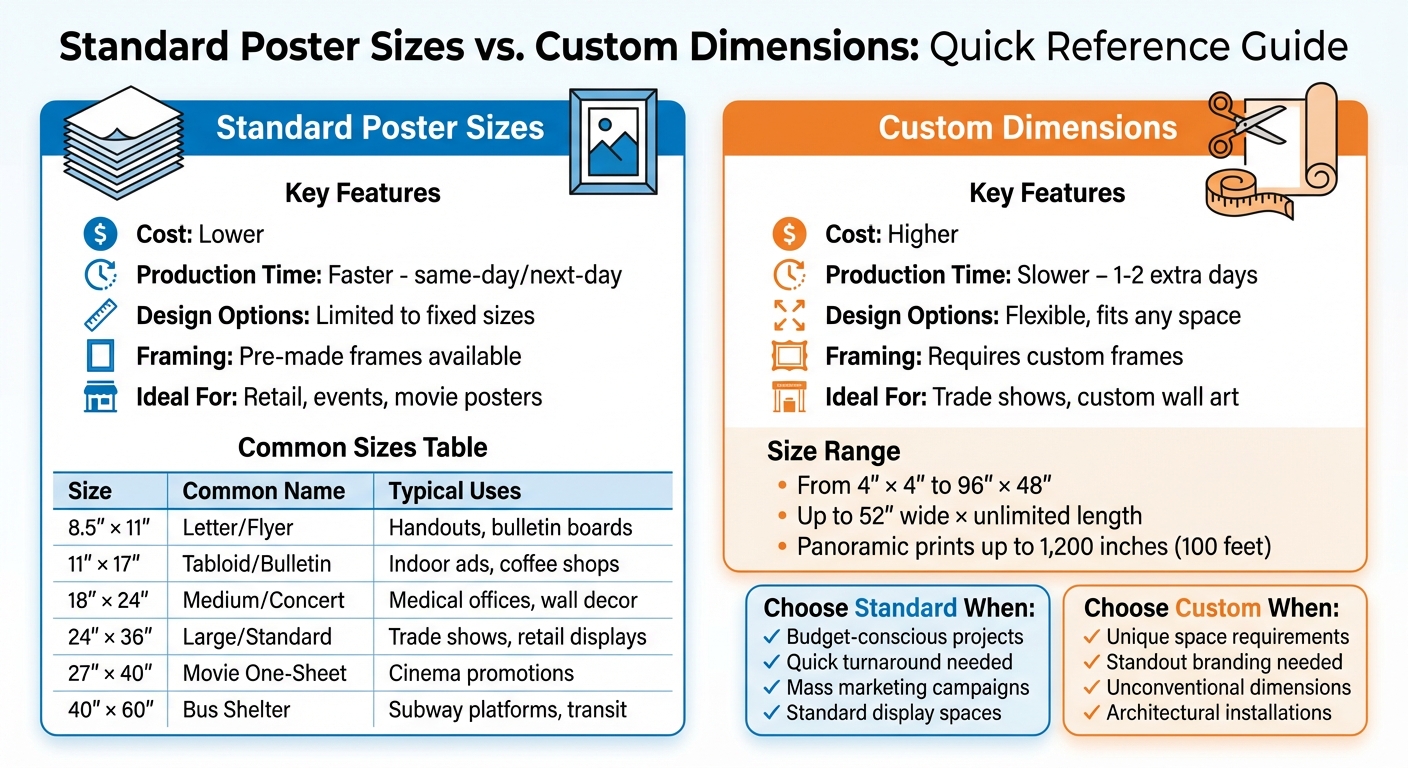

When deciding on poster sizes, you have two main options: standard sizes or custom dimensions. Standard sizes like 11″×17″, 18″×24″, and 24″×36″ are cost-effective, widely available, and quick to produce. They’re perfect for everyday needs like event promotions, retail displays, or office notices. Custom dimensions, on the other hand, give you flexibility to fit unique spaces or create standout designs but are more expensive and take longer to produce.

Key Points:

- Standard Sizes: Affordable, fast, and compatible with pre-made frames. Best for mass marketing or quick projects.

- Custom Dimensions: Tailored for specific needs or unconventional spaces. Ideal for trade shows, branded environments, or unique designs.

- Cost: Standard sizes are cheaper; custom sizes require higher budgets and specialized production.

- Production Time: Standard posters are quicker to print; custom posters add extra time.

- Best Use Cases: Standard works for general advertising; custom is better for unique branding or architectural fits.

Quick Comparison:

| Feature | Standard Poster Sizes | Custom Dimensions |

|---|---|---|

| Cost | Lower | Higher |

| Production Time | Faster (same-day/next-day) | Slower (1–2 extra days) |

| Design Options | Limited to fixed sizes | Flexible, fits any space |

| Framing | Pre-made frames available | Requires custom frames |

| Ideal For | Retail, events, movie posters | Trade shows, custom wall art |

Choose standard sizes for affordability and speed. Opt for custom dimensions when precision and a tailored look are priorities.

Standard vs Custom Poster Sizes Comparison Chart

How To Choose The Right Size For A Poster? – Graphic Design Nerd

Standard Poster Sizes Explained

Standard poster sizes are widely used in the U.S. because they align with the dimensions of common printing equipment, paper rolls, and frames. In the U.S., poster dimensions are typically measured in inches. The most commonly recognized sizes include 11″×17″, 18″×24″, 24″×36″, and 27″×40″. These standard measurements serve as a foundation for understanding poster design.

"Poster design begins with choosing the right dimensions. The correct poster size will determine how your visual and textual elements come together." – UPrinting

Common U.S. Standard Poster Sizes

- 8.5″×11″ (Letter/Flyer): This size is perfect for handouts, bulletin boards, and street posts. It matches standard printer paper, making it easy to print at home or through local print shops.

- 11″×17″ (Tabloid/Bulletin): Often used for small-scale indoor advertisements, like event posters or window displays. It’s a popular choice for coffee shops and other local businesses.

- 18″×24″ (Medium/Concert): This size strikes a balance between compactness and visibility, making it ideal for medical offices, school clubs, and decorative wall posters.

- 24″×36″ (Large/Standard): Known for its versatility, this size is frequently used in trade shows, retail spaces, and outdoor advertising. Its 2:3 aspect ratio ensures it grabs attention even from a distance of up to 50 meters.

- 27″×40″ (Movie One-Sheet): The go-to size for movie posters. Historically, this was slightly larger (27″×41″) until the 1980s, a detail that helps date vintage posters.

- 40″×60″ (Bus Shelter): Designed for high-traffic areas like subway platforms and transit stops, this size ensures visibility for commuters on the move.

Here’s a quick reference table for these sizes, their common names, and typical uses:

| Size (Inches) | Common Name | Primary Uses |

|---|---|---|

| 8.5″ × 11″ | Letter / Flyer | Handouts, community boards, street posts |

| 11″ × 17″ | Bulletin / Tabloid | Indoor ads, coffee shops, event postings |

| 18″ × 24″ | Medium / Concert | Medical offices, wall decor, school clubs |

| 24″ × 36″ | Large / Standard | Trade shows, retail displays, outdoor ads |

| 27″ × 40″ | Movie One-Sheet | Cinema promotions, bus stop ads |

| 40″ × 60″ | Bus Shelter | Subway platforms, transit shelters |

Advantages of Standard Poster Sizes

Using standard poster sizes offers several practical benefits. For starters, they are cost-effective. Since frames, paper rolls, and printing equipment are tailored to these dimensions, there’s no need for custom cutting or additional setup fees. Pre-sized frames for popular sizes like 18″×24″ and 24″×36″ are also widely available, keeping framing costs low.

Another advantage is faster production. Most print shops are equipped to handle standard sizes quickly, often offering same-day or next-day services. Digital printing works well for smaller quantities (1–50 pieces), while offset printing becomes more economical for larger orders.

Standard dimensions also simplify the design process. A wealth of templates and design tools are available for these sizes, making it easier to create polished, professional posters – even for those without a design background.

Finally, standard sizes ensure compatibility with common display spaces. Whether it’s a bus stop, a movie theater lightbox, or a retail display, these dimensions are optimized to fit seamlessly, reducing the risk of printing or display issues.

"By selecting a widely used and standard paper size, you can reduce the amount of guesswork involved in planning for your poster’s proportions." – All Time Design

Disadvantages of Standard Poster Sizes

While standard sizes are practical, they can limit creativity. Fixed dimensions may not always align with a brand’s unique aesthetic or specific design ideas. For instance, a 24″×36″ poster might not stand out in a crowded space where many others share the same format.

Standard sizes can also pose challenges in unconventional display areas. If a wall or display unit has unusual dimensions, these formats might leave awkward gaps or require resizing, which could diminish the overall impact of the design.

Custom Poster Dimensions Explained

While standard poster sizes are practical and convenient, custom dimensions are ideal for those with specific design needs or unique spaces to fill.

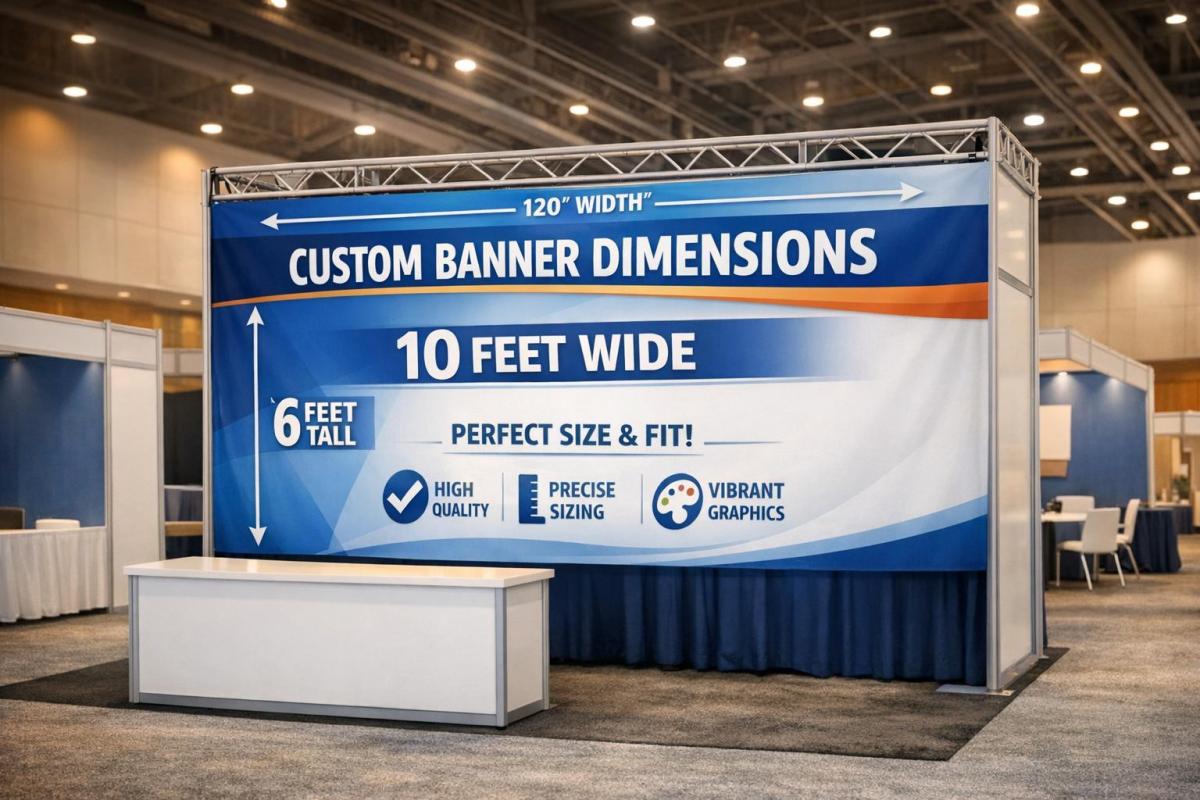

What Custom Dimensions Are

Custom dimensions refer to made-to-order sizes that deviate from standard poster measurements. Unlike standard posters, which are printed on pre-cut sheets, custom posters are printed on large rolls and then trimmed to meet the exact specifications of the design. This method allows for sizes ranging from as small as 4″ × 4″ to as large as 96″ × 48″. Some printers can even produce posters up to 52 inches wide and virtually unlimited lengths, depending on the roll capacity. This level of flexibility opens up possibilities that standard sizes simply can’t match.

Popular custom formats include panoramic prints for wide landscape photos, square designs that mimic social media aesthetics, and oversized backdrops for events, which can stretch up to a staggering 1,200 inches (about 100 feet) in length. For instance, a restaurant might opt for a 30″ × 90″ panoramic print to decorate a narrow hallway, while a trade show booth might require a 10-foot-tall backdrop that doesn’t conform to standard dimensions.

"Custom poster sizing offers some flexibility between standard sizes and can be scaled to dimensions as large as 52 inches wide and any length of your choice." – Thomas Group Printing

Advantages of Custom Dimensions

Custom dimensions shine when it comes to tailored solutions. They ensure an exact fit for unconventional spaces like awkward wall areas, architectural niches, or specific display stands. This precision eliminates the need for resizing or compromising on design, maximizing the visual impact of your poster.

Beyond fitting unique spaces, custom dimensions unleash creative possibilities. They allow for narrow, slide-style designs, long panoramic prints, or unconventional shapes. When it comes to branding, oversized custom posters can make a bold statement in high-traffic locations like gymnasiums, convention centers, or outdoor events. These large-scale prints create a commanding presence that standard sizes just can’t replicate.

Disadvantages of Custom Dimensions

Despite their advantages, custom dimensions come with some drawbacks. First, they are generally more expensive due to their deviation from standard, high-volume production processes. Additionally, custom posters often require longer production times and may need specialized framing or handling, which aren’t as readily available as those for standard formats.

Another consideration is the need for high-quality design files. To avoid blurriness, your files must be set to at least 300 DPI when scaling to custom sizes. Finally, you might also face challenges with displaying or mounting custom posters, as they often require unique solutions or equipment. These factors can add complexity to your project, so it’s important to plan accordingly.

sbb-itb-ce53437

Standard Poster Sizes vs. Custom Dimensions: Side-by-Side Comparison

This section breaks down the key differences between standard and custom poster sizes, helping you weigh the pros and cons for your project.

Comparison Table

Choosing between standard and custom poster sizes often comes down to specific needs like budget, timing, and design flexibility. Here’s a quick comparison:

| Feature | Standard Poster Sizes | Custom Poster Dimensions |

|---|---|---|

| Cost | Lower cost with mass-produced materials | Higher cost due to custom production |

| Production Time | Quick; often same-day or next-day | Typically adds 1–2 extra business days |

| Design Flexibility | Limited to standard aspect ratios | Any size up to 52" wide by any length |

| Framing Options | Widely available off-the-shelf frames | Requires custom-made frames |

| Best Use Cases | Retail, mass marketing, movie promotions | Custom wall art, trade shows, branded environments |

This table highlights the trade-offs, helping you determine which option suits your project best.

When to Use Standard Sizes

Standard sizes are the go-to option for projects where speed and affordability are top priorities. They are ideal for large-scale campaigns like retail promotions, where hundreds or even thousands of posters need to be printed quickly using offset printing methods. Common sizes like 18" × 24" or 24" × 36" are popular in settings such as medical offices, concert venues, and trade show booths because they strike a balance between visibility and ease of display.

If your project demands quick turnaround and widely available framing, standard sizes are a practical choice.

When to Use Custom Dimensions

Custom dimensions shine in projects that require a tailored fit or a standout design. For example, trade show backdrops often exceed standard dimensions to create a striking visual impact. Similarly, branded office walls, museum exhibits, and architectural installations benefit from custom sizes that align perfectly with specific wall spaces or design goals.

Unique formats like panoramic prints – such as 11.75" × 36" – are perfect for creating attention-grabbing displays in restaurant hallways or retail windows where typical shapes fall short. Outdoor signage, especially in high-traffic areas like gymnasiums or convention centers, often pairs custom dimensions with durable materials like 20 mil styrene or PVC board for weather resistance. Additionally, custom square formats can mimic social media aesthetics, offering a creative edge for modern branding.

For projects where creativity and precision are key, custom dimensions open up endless possibilities.

How to Choose Between Standard and Custom Poster Sizes

Factors to Consider

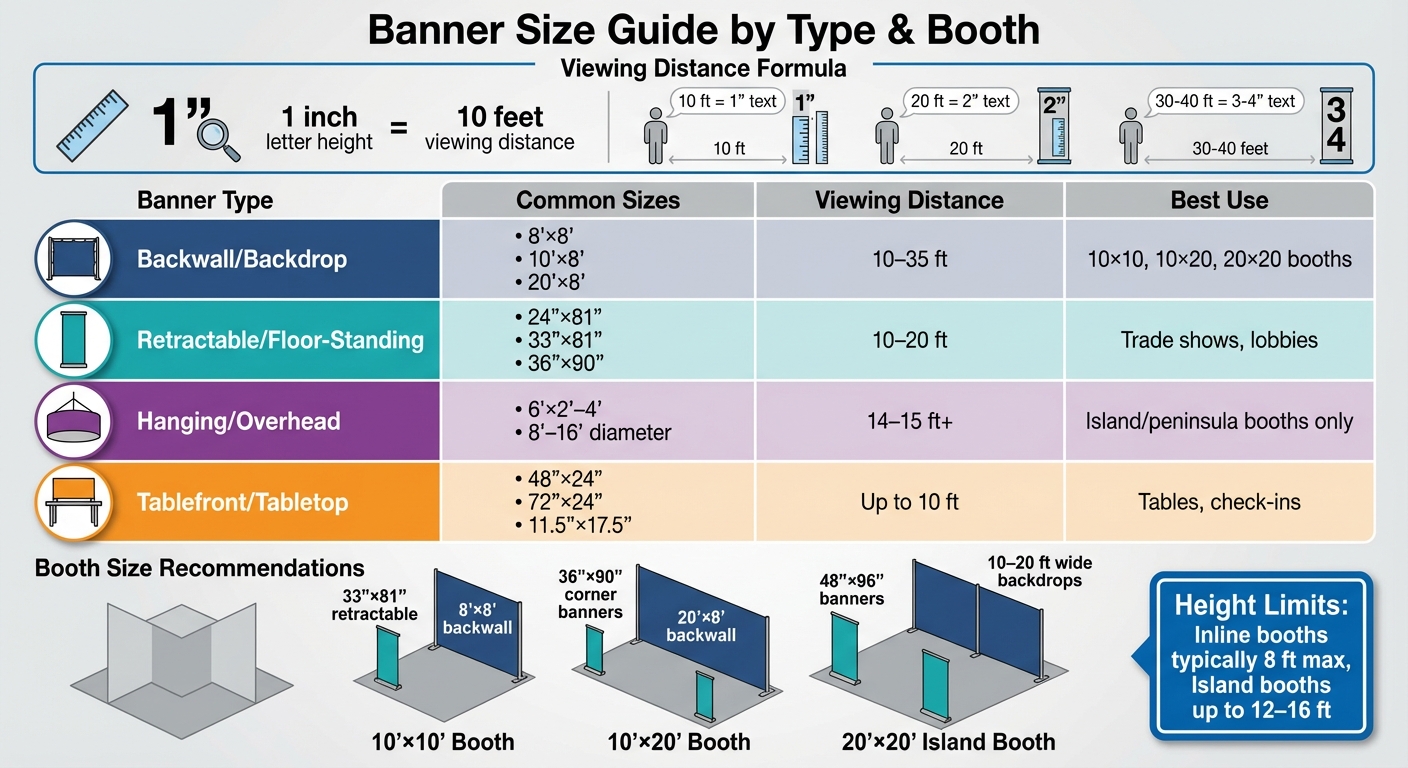

Picking the right poster size can make or break its visibility and overall design impact. One of the most important considerations is viewing distance. Smaller sizes like 8.5″×11″ or 11″×17″ are ideal for close-up viewing, while larger formats, such as 24″×36″ or bigger, are better suited for high-traffic areas where they need to grab attention from afar. A helpful tip? Use a font size of at least one inch tall (72 pt) for every 10 feet of viewing distance.

Location also plays a big role. Posters displayed outdoors should be printed on durable, weather-resistant materials to withstand the elements. For indoor settings, standard paper and readily available frames usually work just fine.

Another key factor is content density. If your design is heavy on text, like a menu or schedule, you’ll need a larger size to ensure everything stays legible. On the other hand, posters focused on imagery can benefit from bigger formats to maintain the quality and impact of visuals. Don’t forget to leave enough white space to keep text-heavy designs clean and easy to read.

Finally, think about your budget. Standard poster sizes are generally more affordable since frames, paper rolls, and printing materials are mass-produced in these dimensions.

Once you’ve considered these factors, the next step is to explore how working with a professional print shop can elevate your project.

Working with a Professional Print Shop

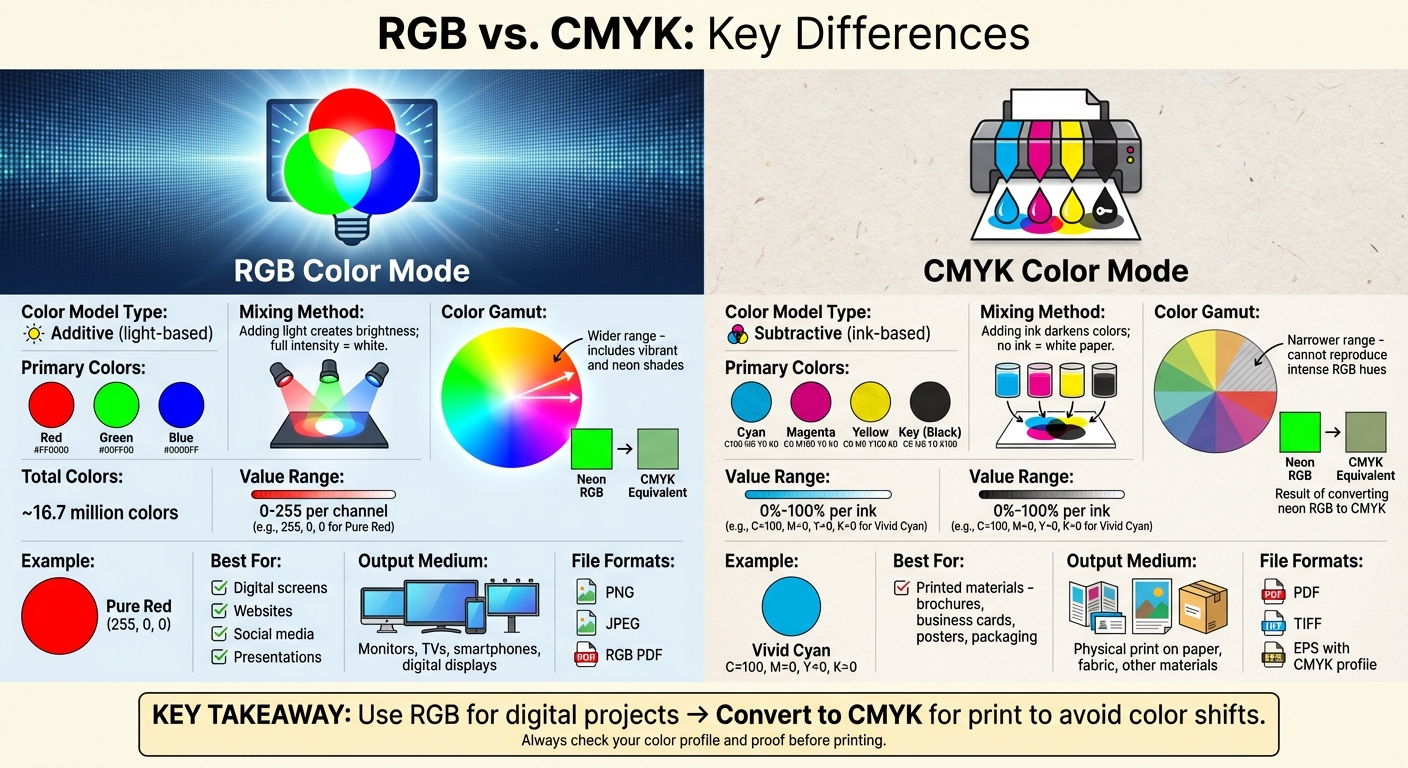

After narrowing down your poster size and design considerations, collaborating with a professional print shop can take your project to the next level. A full-service print shop like Miro Printing & Graphics Inc. ensures your posters look polished and professional from start to finish. Their team can provide valuable input on design scalability, ensure your files are set up correctly in CMYK color space, and verify details like bleed margins (typically 0.125″) and a resolution of 300 DPI to avoid any blurry prints.

Miro Printing & Graphics Inc. also offers options like mounting, lamination, and UV coating to enhance your poster’s visual appeal while keeping costs in check. One happy customer, Julia I., shared her experience, saying the team completed a "complex job in record time for a very reasonable price" and even provided a video of the print sample for approval.

"The end result is a finished piece that exceeds your highest expectations but never your budget!" – Miro Printing & Graphics Inc.

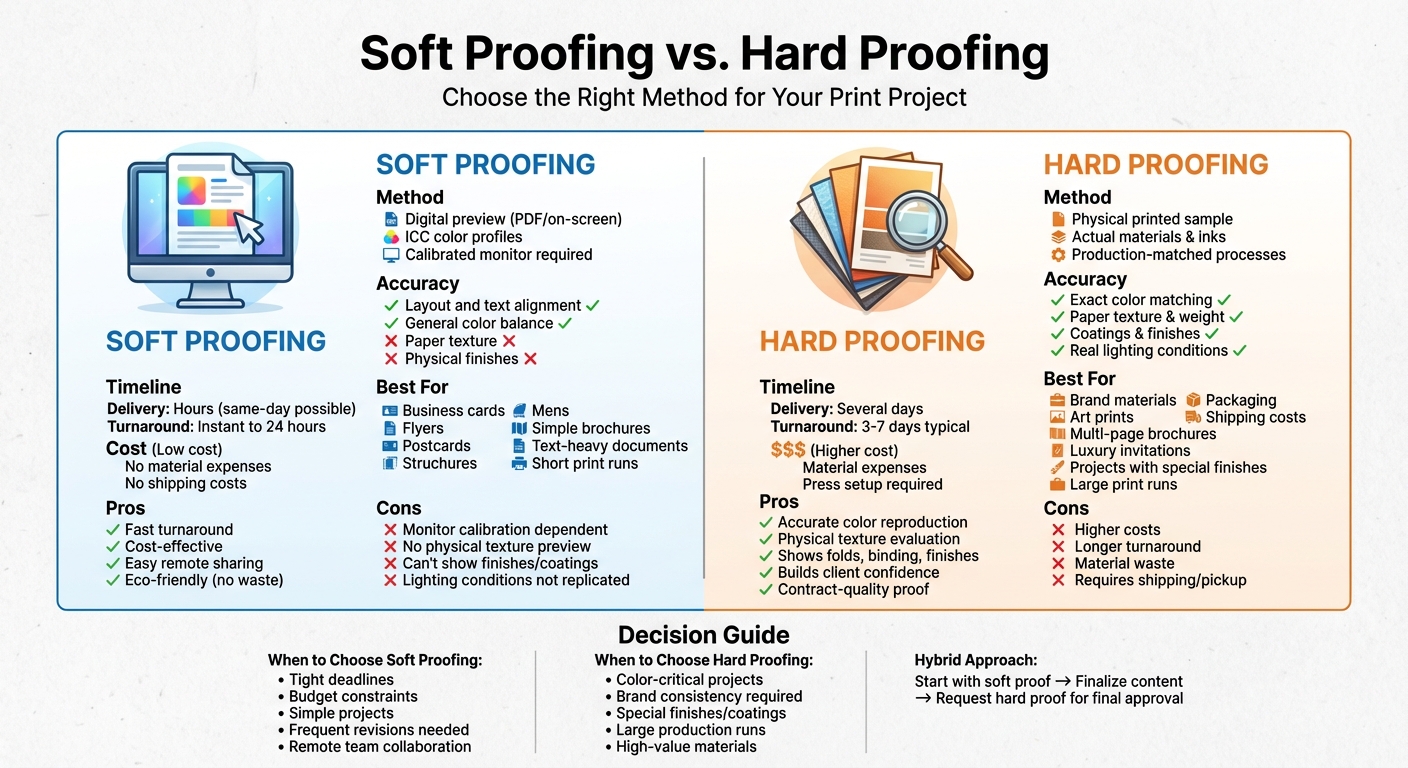

Before committing to a full print run, always request a digital or physical proof. This step is essential for catching any last-minute changes and avoiding the expense of printing multiple sizes just to find the right fit.

Conclusion

When deciding on poster sizes, standard dimensions offer affordability and quick production, while custom sizes provide flexibility for unique designs. Sizes like 11″×17″, 18″×24″, and 24″×36″ are perfect for fast and budget-friendly projects, such as retail promotions, event announcements, or office displays. On the other hand, custom dimensions are ideal for spaces with unusual architectural features or specific branding needs, giving you more control over the final look.

Standard sizes are great for everyday use, but custom options shine when you need something designed to stand out. Consider factors like viewing distance, location, content density, and budget when making your choice. Finding the right balance between practicality and creativity ensures your poster makes the desired impact.

For a seamless experience, consult a professional print shop. Miro Printing & Graphics Inc. specializes in both standard and custom poster printing. They can guide you through file setup, material choices, and finishing touches. Their expertise ensures your design scales properly, colors print accurately in CMYK, and the final product delivers sharp visuals at 300 DPI.

"Great customer service that we didn’t get with our old online printer – attention to detail is what makes the difference!" – Mike B.

With expert guidance, you can avoid costly mistakes and create a poster that leaves a lasting impression – whether you stick to a classic size or explore custom dimensions.

FAQs

What should I consider when deciding between standard and custom poster sizes?

Choosing the right poster size boils down to what you need and the purpose it serves. Standard sizes – like 8.5 × 11 in, 11 × 17 in, 18 × 24 in, 24 × 36 in, and 27 × 40 in – are popular for a reason. They’re budget-friendly, easy to work with, and compatible with most frames, paper rolls, and mounting tools. Plus, they’re a go-to for quick projects since many templates and design software already support these dimensions. That said, standard sizes might not always fit the bill if you’re working with unique spaces or aiming for a standout design.

If you’re after something more tailored, custom sizes might be the way to go. They’re perfect for fitting specific display areas, showcasing panoramic visuals, or highlighting bold headlines. When considering custom dimensions, think about factors like the display location, how far away people will view it, the balance of text and images, and, of course, your budget. Just remember, custom sizes can come with higher costs for materials and setup, and they might require special framing or mounting solutions.

For those looking for expert help, Miro Printing & Graphics Inc. in Hackensack, NJ, offers both standard and custom large-format printing. Their team can guide you through the process, ensuring you get the right size for your project without overspending.

How do custom poster sizes affect cost and production time?

Custom poster sizes can take more time to produce and cost more than standard sizes. Why? Standard dimensions are easier and cheaper to work with because they use pre-cut materials, commonly available paper rolls, and standard frames. This streamlines the entire process, keeping costs and production times down. On the other hand, custom sizes often require extra steps like cutting paper to precise measurements or tweaking press settings. These adjustments can lead to more material waste and longer production times.

That said, custom sizes bring a level of flexibility that standard options just can’t match. They’re perfect for fitting unique spaces, meeting specific branding requirements, or creating standout displays. If you’re considering custom dimensions, it’s smart to plan ahead. Decide on your measurements early, and carefully weigh the benefits of getting the exact fit you want against the potential for higher costs and longer production timelines.

When should I choose custom poster dimensions instead of standard sizes?

Custom poster sizes are a great solution when standard dimensions just won’t cut it. They’re perfect for projects that demand specific proportions – like aligning with a company’s branding, creating eye-catching outdoor displays, or designing indoor pieces such as gallery artwork, directional signs, or window displays that need to fit snugly into a particular space.

Businesses often choose custom dimensions for trade shows, pop-up events, or office décor. This ensures their posters fit seamlessly into unique booth setups, wall areas, or promotional themes. Whether it’s a sleek, narrow banner or a large-scale display, custom posters let you craft your message and design exactly how you envision it.

At Miro Printing & Graphics Inc. in Hackensack, NJ, you can bring your vision to life with custom posters in any size. Using advanced large-format and digital printing technology, they deliver high-quality results quickly, ensuring your posters are both striking and perfectly tailored to your business or event needs.

Related Blog Posts

- Paper Sizes for Commercial Printing Explained

- Offset vs. Digital: Paper Size Considerations

- Standard Print Sizes Explained

- Standard Booklet Sizes for Printing

https://app.seobotai.com/banner/banner.js?id=694c870912e0ddc125fc35b4